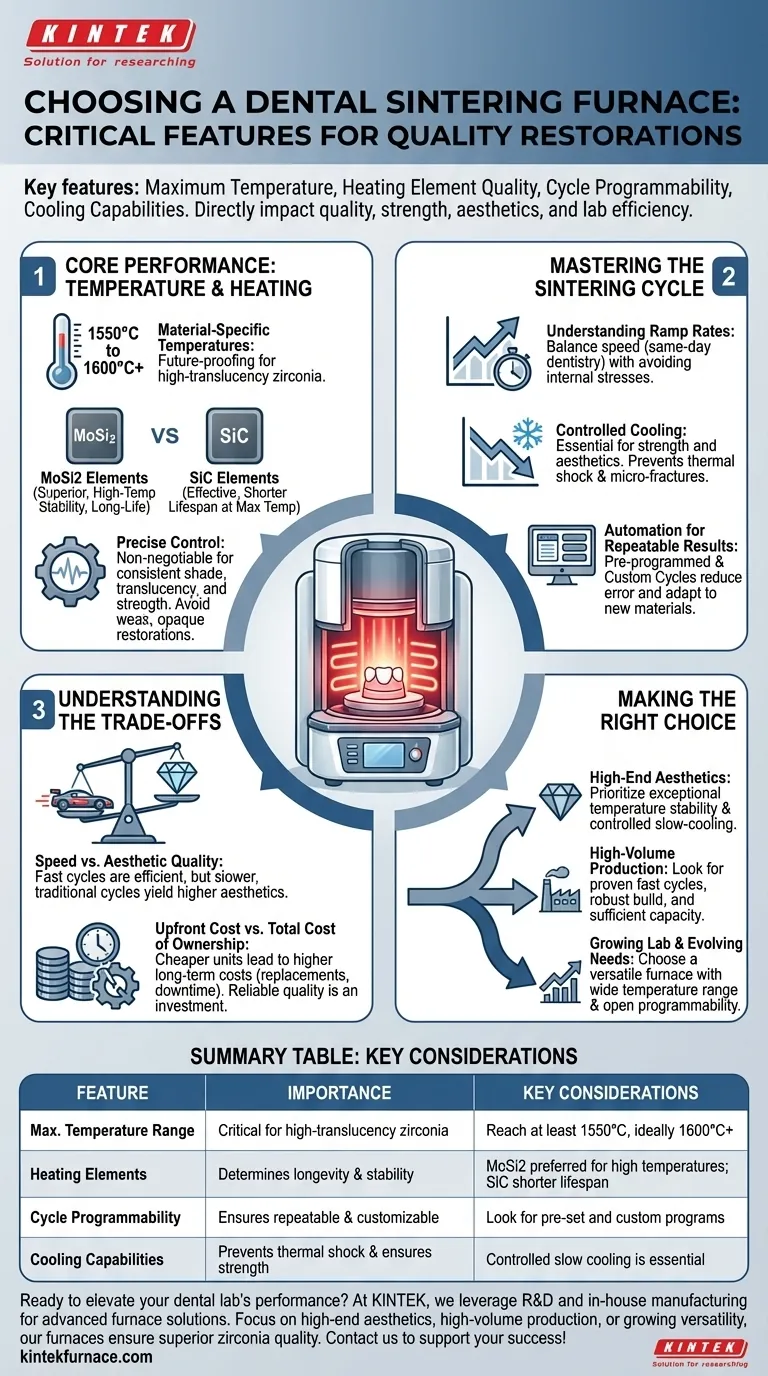

When choosing a dental sintering furnace, the most critical features to evaluate are its maximum temperature range, the quality of its heating elements, its cycle programmability, and its cooling capabilities. These technical specifications directly determine the quality, strength, and aesthetics of your zirconia restorations, as well as the overall efficiency of your lab's workflow.

Choosing a sintering furnace is not about finding the most features, but about aligning the unit's core capabilities with your specific material requirements and production goals. The right decision hinges on understanding how each component impacts the final restoration and your long-term operational costs.

The Core of Performance: Temperature and Heating

The fundamental purpose of a sintering furnace is to apply heat precisely. This capability is determined by its temperature range and the components that generate and control the heat.

Achieving Material-Specific Temperatures

Most modern zirconia materials, especially high-translucency varieties, require sintering temperatures of at least 1550°C, with some newer materials pushing toward 1600°C.

Choosing a furnace that can comfortably reach and sustain these higher temperatures is a crucial step in future-proofing your lab. A unit that struggles at its maximum rated temperature will wear out faster and produce inconsistent results.

The Role of Heating Elements

The heating elements are the engine of your furnace. The two most common types are Molybdenum Disilicide (MoSi2) and Silicon Carbide (SiC).

MoSi2 elements are generally considered the superior choice for high-temperature zirconia sintering. They offer excellent longevity and stability at very high temperatures, protecting them from the degradation that can lead to inconsistent heating.

SiC elements are also effective but may have a shorter operational lifespan when consistently run at the highest end of the temperature spectrum.

Why Precise Control is Non-Negotiable

The final shade, translucency, and strength of a restoration are directly linked to hitting and holding a precise target temperature.

A furnace with poor temperature accuracy can result in restorations that are weak, opaque, or off-shade, leading to costly remakes and patient dissatisfaction. Look for furnaces that guarantee a high degree of temperature uniformity throughout the chamber.

Efficiency vs. Quality: Mastering the Sintering Cycle

A sintering cycle isn't just about reaching a peak temperature; it's a carefully controlled process of heating and cooling.

Understanding Ramp Rates

The "ramp rate" is the speed at which the furnace heats up. While faster ramp rates can enable quicker cycles for same-day dentistry, they must be executed without compromising the zirconia.

An overly aggressive heating phase can introduce internal stresses in the material before it is fully sintered.

The Critical Importance of Controlled Cooling

How the furnace cools is just as important as how it heats. Rapid cooling can cause thermal shock, leading to micro-fractures that weaken the final restoration, even if they aren't visible.

A high-quality furnace allows you to program a slow, controlled cooling phase, which is essential for achieving maximum strength and aesthetic quality, particularly with large or complex bridge structures.

Automation for Repeatable Results

Look for a furnace with both pre-programmed cycles for common materials and the ability to create and save custom programs.

Pre-set programs reduce the risk of human error and ensure consistency. The ability to program custom cycles gives you the flexibility to adopt new materials as they come to market without needing to replace your furnace.

Understanding the Trade-offs

Making an informed decision requires acknowledging the inherent compromises between cost, speed, and ultimate quality.

Speed vs. Aesthetic Quality

Fast-sintering cycles are a significant workflow advantage, but they can sometimes come at a small cost to the final aesthetic.

The most highly translucent results are often achieved with slower, more traditional cycles. You must decide if your priority is maximum efficiency for single units or achieving the absolute highest level of aesthetics for demanding cosmetic cases.

Upfront Cost vs. Total Cost of Ownership

A less expensive furnace may save you money initially but can lead to higher long-term costs. Cheaper components, especially heating elements and insulation, may require more frequent replacement.

Consider the cost of downtime. A reliable furnace from a reputable manufacturer with robust build quality is an investment in your lab's uninterrupted operation.

Feature-Rich vs. Mission-Critical

Advanced features like wireless connectivity for remote monitoring can improve workflow convenience, but they are not essential to producing a high-quality restoration.

Focus first on the core performance factors: temperature accuracy, reliable heating elements, and precise cycle control. Extra features are only valuable if they solve a specific problem in your workflow.

Making the Right Choice for Your Lab

Your choice of furnace should be a strategic decision based on your primary business objectives.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with exceptional temperature stability, uniform chamber heating, and programmable slow-cooling cycles.

- If your primary focus is high-volume production or same-day dentistry: Look for a furnace with proven fast-sintering cycles, a robust build quality for constant use, and sufficient capacity for your throughput.

- If you are a growing lab with evolving needs: Choose a versatile furnace with a wide temperature range (up to 1600°C or more) and open programmability to accommodate new materials.

Ultimately, the right furnace is a strategic investment that secures your lab's quality, efficiency, and future-readiness.

Summary Table:

| Feature | Importance | Key Considerations |

|---|---|---|

| Maximum Temperature Range | Critical for sintering high-translucency zirconia | Should reach at least 1550°C, ideally 1600°C for future-proofing |

| Heating Elements | Determines longevity and heating stability | MoSi2 preferred for high temperatures; SiC may have shorter lifespan |

| Cycle Programmability | Ensures repeatable and customizable sintering | Look for pre-set and custom programs for consistency and flexibility |

| Cooling Capabilities | Prevents thermal shock and ensures strength | Controlled slow cooling is essential for complex restorations |

Ready to elevate your dental lab's performance? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you focus on high-end aesthetics, high-volume production, or growing versatility, our sintering furnaces ensure superior zirconia restoration quality, efficiency, and future-readiness. Contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations