At its core, an experimental box-type atmosphere furnace is made easy to operate through a combination of intelligent automation and thoughtful design. Modern furnaces integrate intuitive controls, smart systems, and clear display panels that allow users to effortlessly set, monitor, and adjust critical parameters like temperature and atmospheric conditions. This automation significantly lowers the barrier to entry, reducing the need for specialized operator skills and boosting the efficiency of experiments.

The key to modern furnace usability is not just about simpler buttons. It's about shifting the complex burden of maintaining precise, stable, and repeatable experimental conditions from the human operator to the machine itself.

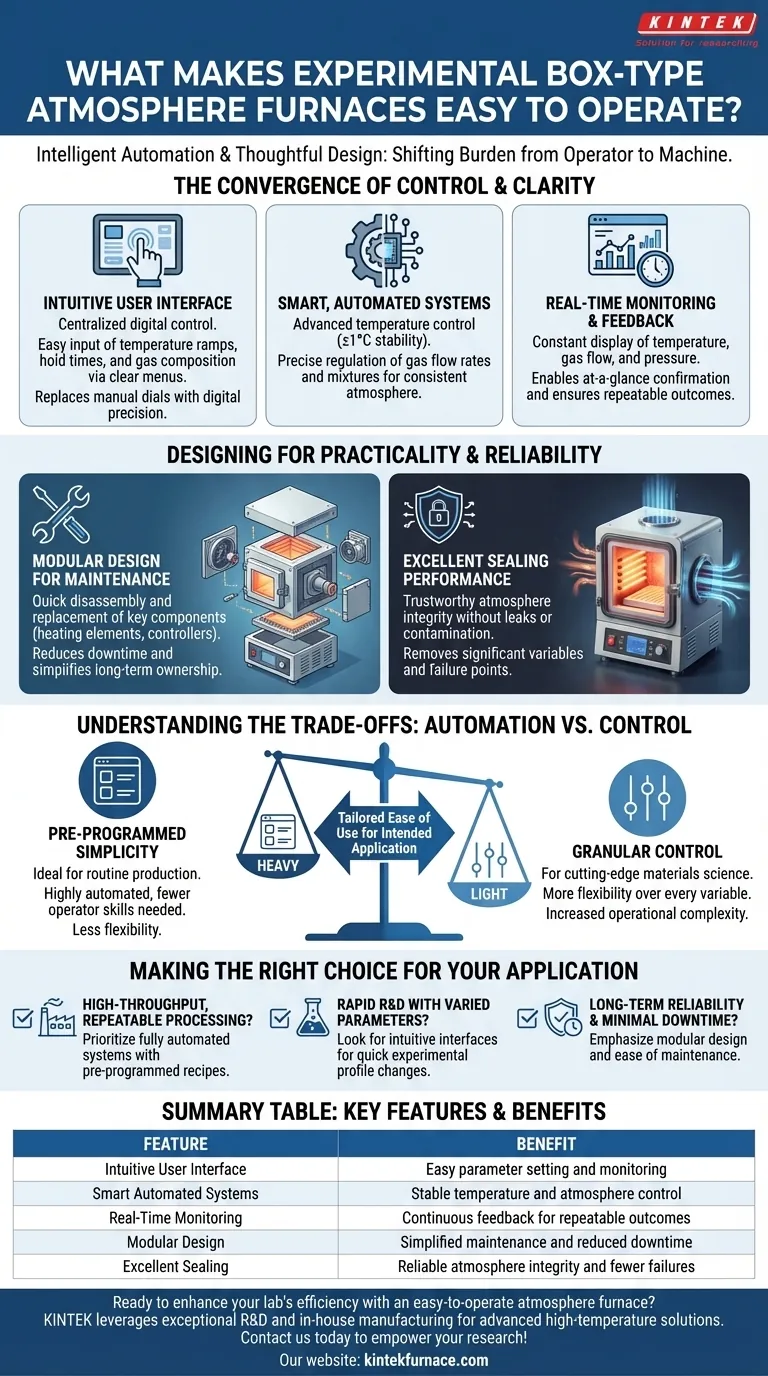

The Convergence of Control and Clarity

Ease of use in a technical instrument is born from the seamless interaction between the operator and the machine's core functions. For an atmosphere furnace, this means providing direct control without overwhelming complexity.

The Intuitive User Interface

The most visible feature is the user-friendly interface. These are typically digital display panels that provide a centralized hub for all operations.

Operators can easily input desired temperature ramp rates, hold times, and gas compositions through a clear menu system. This replaces archaic manual dials and guesswork with digital precision.

Smart, Automated Systems

Behind the simple interface lies a powerful network of automated systems. These are the true workhorses that ensure process stability.

Advanced temperature control systems use sophisticated sensors and algorithms to maintain chamber temperature with exceptional stability, often with variations as low as ±1°C.

Simultaneously, atmosphere control systems use mass flow controllers and sensors to precisely regulate gas flow rates and mixtures, ensuring the internal environment remains exactly as specified throughout the experiment.

Real-Time Monitoring and Feedback

An easy-to-operate furnace provides constant, clear feedback. The display panel shows the current temperature, gas flow, and pressure levels in real-time.

This continuous monitoring allows the operator to confirm at a glance that the experiment is running correctly and provides the data needed to ensure repeatable outcomes.

Designing for Practicality and Reliability

Beyond the control panel, the physical and structural design of the furnace plays a critical role in its day-to-day usability and long-term reliability.

Modular Design for Maintenance

Many modern furnaces feature a modular design. This means key components like heating elements or controllers can be quickly disassembled, replaced, or serviced.

This approach dramatically reduces downtime and simplifies maintenance, making the furnace more reliable and less complex to own over its lifespan.

Excellent Sealing Performance

The integrity of the furnace's atmosphere is paramount. A high-quality seal is not just a performance feature; it's an operational one.

Excellent sealing means the operator can trust the system to maintain the desired atmosphere without leaks or contamination. This removes a significant variable and point of failure, simplifying the entire experimental process.

Understanding the Trade-offs: Automation vs. Granular Control

While automation greatly simplifies operation, it's important to understand the inherent trade-offs. The level of automation and control is directly related to the furnace's intended application.

Pre-Programmed Simplicity

Systems designed for routine production or standardized tests often feature highly automated, pre-programmable cycles. This is incredibly easy to use but may offer less flexibility for novel, exploratory research where parameters change frequently.

Customization and Complexity

Conversely, a furnace designed for cutting-edge materials science might offer more granular control over every variable. While more powerful, this flexibility inherently increases operational complexity and requires a more skilled operator. The "ease of use" is tailored to the expertise of the intended user.

Making the Right Choice for Your Application

Selecting a furnace requires matching its features to your primary goal. The definition of "easy to operate" changes based on your specific research or production needs.

- If your primary focus is high-throughput, repeatable processing: Prioritize a furnace with fully automated temperature and atmosphere control systems that support pre-programmed recipes.

- If your primary focus is rapid research and development with varied parameters: Look for a system with an exceptionally intuitive interface that allows for quick and easy changes to experiment profiles without deep programming.

- If your primary focus is long-term reliability and minimal downtime: Emphasize a modular design and investigate the ease of routine maintenance and the availability of replacement parts.

Ultimately, the right furnace empowers you to focus on your experiment, not the equipment.

Summary Table:

| Feature | Benefit |

|---|---|

| Intuitive User Interface | Easy parameter setting and monitoring |

| Smart Automated Systems | Stable temperature and atmosphere control |

| Real-Time Monitoring | Continuous feedback for repeatable outcomes |

| Modular Design | Simplified maintenance and reduced downtime |

| Excellent Sealing | Reliable atmosphere integrity and fewer failures |

Ready to enhance your lab's efficiency with an easy-to-operate atmosphere furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Box-Type Atmosphere Furnaces. Our products, such as Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today via our contact form to discuss how we can empower your research with reliable, user-friendly equipment!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation