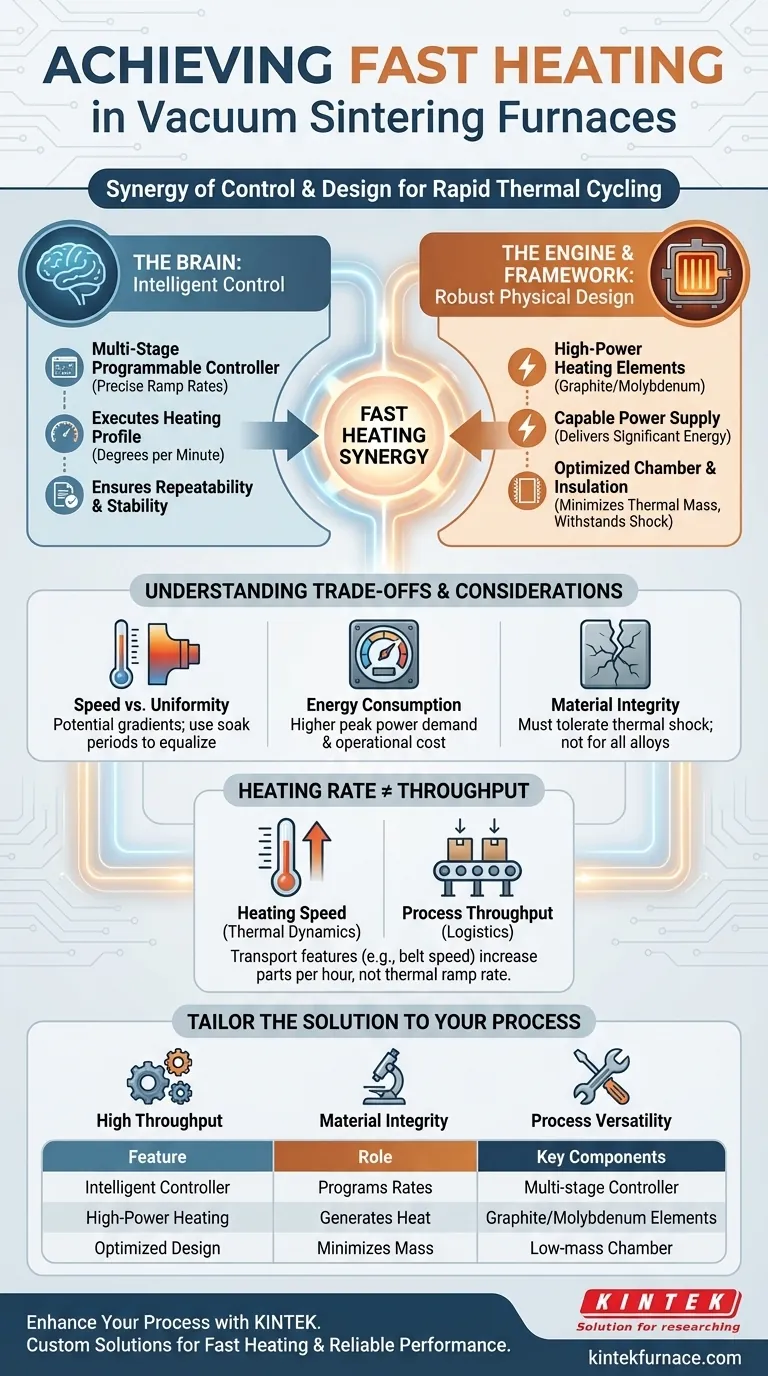

At its core, a vacuum sintering furnace's ability to meet fast heating requirements depends on the synergy between its control system and its fundamental physical design. The key features are an intelligent, programmable temperature controller that dictates the heating rate, and a robust heating system—including powerful elements and a capable power supply—designed to execute those commands swiftly and reliably.

The critical insight is that achieving rapid heating is not about a single component, but the integrated performance of the entire thermal system. A furnace must be specifically engineered for rapid thermal cycling, from its power source to its control logic, to ensure both speed and process repeatability.

The Core Components for Rapid Heating

To understand how a furnace achieves fast heating, we must look at the components responsible for generating, delivering, and controlling thermal energy. These elements work together as a cohesive system.

The Intelligent Temperature Controller: The Brain

The furnace's "brain" is its multi-stage intelligent program-controlled temperature controller. This is the most critical feature for executing a precise heating profile.

Its primary function is to allow operators to program a specific temperature ramp rate—measured in degrees per minute or hour. For a fast heating process, you would program a high ramp rate. The "multi-stage" capability means you can set different rates for different phases of the cycle, allowing for an initial rapid climb followed by a slower, controlled soak.

This programmability ensures repeatability and stability, guaranteeing that every batch undergoes the exact same thermal profile, which is crucial for quality control.

High-Power Heating System: The Engine

A programmable controller is ineffective without a physical system capable of generating heat quickly. The furnace's heating elements and power supply act as the engine.

Furnaces designed for fast heating rates are equipped with high-power heating elements, often made from materials like graphite or molybdenum, which can handle high electrical loads and reach target temperatures very quickly.

The furnace's power supply must be sized appropriately to deliver the significant energy required to drive these elements at full capacity, enabling a rapid increase in chamber temperature.

Optimized Furnace Design: The Framework

The overall design of the furnace chamber and its insulation is the final piece. The insulation must not only contain the heat but also be capable of withstanding the thermal shock associated with rapid heating and cooling cycles.

Furthermore, the design focuses on minimizing thermal mass where possible, as heating excess material slows down the response time of the system. This is a key consideration in custom-designed furnaces, where the heating rate is a specified design parameter.

Differentiating Process Speed from Heating Speed

It's important to distinguish between the speed of the heating cycle itself and the overall throughput of the furnace. Some features improve process efficiency but do not directly affect the thermal ramp rate.

The Role of Material Transport

Features like a variable frequency stepless speed regulation and a stainless steel mesh belt transmission relate to how products are moved through the furnace, typically in a continuous or semi-continuous model.

While a faster belt speed increases the number of parts processed per hour (throughput), it does not change the rate at which the furnace's heating zone can increase its temperature. These features are about process logistics, not thermal dynamics.

Understanding the Trade-offs

Specifying a furnace for fast heating involves balancing competing priorities. Speed is valuable, but it comes with considerations that impact quality and cost.

Speed vs. Temperature Uniformity

Rapidly heating a part can create significant temperature gradients, where the surface is much hotter than the core. This can lead to incomplete sintering, internal stresses, or warping, especially in larger or thicker components. A multi-stage controller helps mitigate this by allowing a slower, equalizing soak period after the initial fast ramp.

Energy Consumption and Cost

Achieving a high ramp rate requires a massive input of electrical power in a short amount of time. This translates directly to higher peak energy consumption and potentially higher operational costs compared to a slower, more gradual heating process.

Material Integrity and Thermal Shock

Not all materials or part geometries can withstand the stress of rapid heating. The process must be designed around the material's tolerance for thermal shock. A fast heating cycle that works for one alloy may cause another to crack or fail.

Making the Right Choice for Your Process

Your ideal furnace specification depends entirely on the requirements of your material and your production goals.

- If your primary focus is high throughput for robust parts: Specify a furnace with a high-watt-density heating system and a power supply engineered for rapid cycling.

- If your primary focus is material integrity and precision: Prioritize a sophisticated, multi-stage temperature controller that allows you to finely tune the balance between heating speed and thermal soaking.

- If your primary focus is process versatility: Ensure the furnace's controller and heating system are rated for a wide range of programmable ramp rates to accommodate different products and materials.

Ultimately, selecting the right furnace is about precisely matching its engineered capabilities to the specific demands of your sintering process.

Summary Table:

| Feature | Role in Fast Heating | Key Components |

|---|---|---|

| Intelligent Temperature Controller | Programs and controls precise heating ramp rates | Multi-stage programmable controller |

| High-Power Heating System | Generates heat quickly for rapid temperature increases | Graphite/molybdenum elements, robust power supply |

| Optimized Furnace Design | Minimizes thermal mass and withstands thermal shock | Insulation, low-mass chamber |

Ready to enhance your sintering process with a custom high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for fast heating and reliable performance. Contact us today to discuss how we can optimize your thermal processing!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures