Choosing a sintering furnace is a critical investment that directly impacts product quality, operational efficiency, and your bottom line. The decision hinges on three core pillars: the specific materials you are processing, your required production volume and speed, and the operational constraints of your environment, such as budget and user skill.

The optimal furnace is not the one with the most features, but the one whose technical capabilities—temperature, atmosphere, and capacity—are precisely aligned with your specific application. A mismatch in any of these fundamental areas will inevitably lead to compromised quality, process inefficiency, and wasted resources.

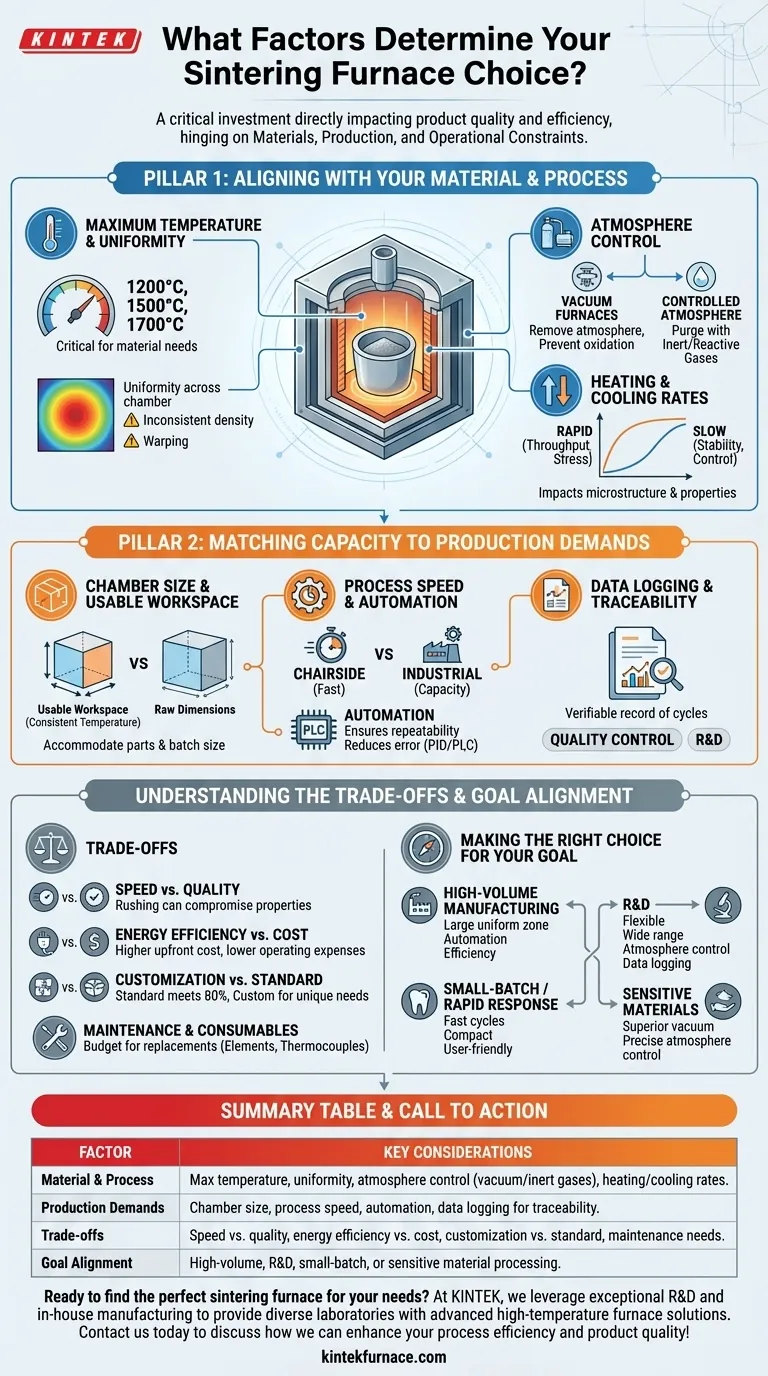

Pillar 1: Aligning with Your Material and Process

The first and most critical step is to define the non-negotiable requirements of the material you intend to sinter. This determines the fundamental technical specifications of the furnace.

Maximum Temperature and Uniformity

The furnace must be able to safely reach and sustain the required sintering temperature for your material. Common maximum operating temperatures are 1200°C, 1500°C, and 1700°C.

Equally important is temperature uniformity across the entire chamber. Poor uniformity can lead to inconsistent density, warping, or incomplete sintering in different parts of your batch.

Atmosphere Control

Many materials, especially metals and certain advanced ceramics, will oxidize or react undesirably if heated in air. Atmosphere control is essential for managing the chemical environment during the cycle.

Your options include:

- Vacuum Furnaces: Remove atmosphere to prevent oxidation and contamination. The required vacuum level (e.g., high vacuum vs. ultra-high vacuum) depends on the material's sensitivity and purity requirements.

- Controlled Atmosphere Furnaces: Purge the chamber with an inert gas (like Argon or Nitrogen) to displace oxygen or introduce reactive gases for specific surface treatments.

Heating and Cooling Rates

The speed at which the furnace heats up and cools down has a significant impact on the material's final microstructure and properties.

Rapid heating/cooling rates increase throughput but can induce thermal shock or internal stresses in sensitive parts. Slower, more controlled ramps are often necessary to ensure dimensional stability and consistent results.

Pillar 2: Matching Capacity to Your Production Demands

Once material needs are met, you must align the furnace's capabilities with your workflow and production goals.

Chamber Size and Usable Workspace

The furnace's internal chamber size must accommodate your parts and batch size. Consider not just the raw dimensions, but the usable workspace—the area that maintains consistent temperature uniformity.

Evaluate your typical batch size and the dimensions of your largest parts to avoid a production bottleneck.

Process Speed and Automation

Consider your required throughput. A furnace for chairside dental applications prioritizes extremely fast cycles, while a furnace for industrial production may prioritize capacity and consistency over raw speed.

Process automation capabilities, ranging from simple PID controllers for temperature regulation to advanced PLC systems, ensure repeatability and reduce the chance of operator error. These systems can manage multi-stage programs with precise control over temperature, atmosphere, and dwell times.

Data Logging and Traceability

For quality control, R&D, and certified production environments, the ability to log process data is crucial. This provides a verifiable record of each sintering cycle, ensuring traceability and helping diagnose any production issues.

Understanding the Trade-offs

Every furnace design represents a series of engineering compromises. Understanding these trade-offs is key to making an informed choice.

Speed vs. Final Quality

While fast sintering cycles are attractive for productivity, they are not always ideal. Rushing the process can lead to incomplete sintering or internal stresses, compromising the mechanical properties of the final part. Always verify that a "fast" cycle can deliver the quality you require.

Energy Efficiency vs. Initial Cost

Furnaces with advanced insulation, modern heating elements, and efficient power supplies consume significantly less energy. While these models often have a higher upfront cost, the savings in long-term operating expenses can be substantial, especially in high-volume settings.

Customization vs. Standard Models

A standard, off-the-shelf furnace may meet 80% of your needs at a lower cost. However, for unique processes or materials, a customized furnace with specific chamber dimensions, atmosphere options, or control systems may be necessary to achieve optimal results.

Maintenance and Consumables

A furnace is not a one-time purchase. Budget for ongoing maintenance and the replacement of consumables like heating elements, thermocouples, and vacuum seals. Inquire about the lifespan and cost of these components before purchasing.

Making the Right Choice for Your Goal

Select a furnace by methodically matching its specifications to your primary objective.

- If your primary focus is high-volume manufacturing: Prioritize a furnace with a large, uniform heating zone, robust automation for repeatability, and high energy efficiency to minimize operating costs.

- If your primary focus is research and development (R&D): Choose a flexible furnace with a wide temperature range, versatile atmosphere control options, and comprehensive data logging capabilities.

- If your primary focus is small-batch or rapid-response production (e.g., dental labs): Focus on fast cycle times, a compact footprint, and an intuitive, user-friendly interface to minimize training and operational errors.

- If your primary focus is processing highly sensitive or reactive materials: Invest in superior vacuum levels and precise, verifiable atmosphere control systems to guarantee material purity and integrity.

By systematically evaluating your needs against these core principles, you can select a furnace that serves as a reliable foundation for your work for years to come.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material & Process | Maximum temperature, uniformity, atmosphere control (vacuum/inert gases), heating/cooling rates |

| Production Demands | Chamber size, process speed, automation, data logging for traceability |

| Trade-offs | Speed vs. quality, energy efficiency vs. cost, customization vs. standard models, maintenance needs |

| Goal Alignment | High-volume, R&D, small-batch, or sensitive material processing |

Ready to find the perfect sintering furnace for your needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your process efficiency and product quality!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability