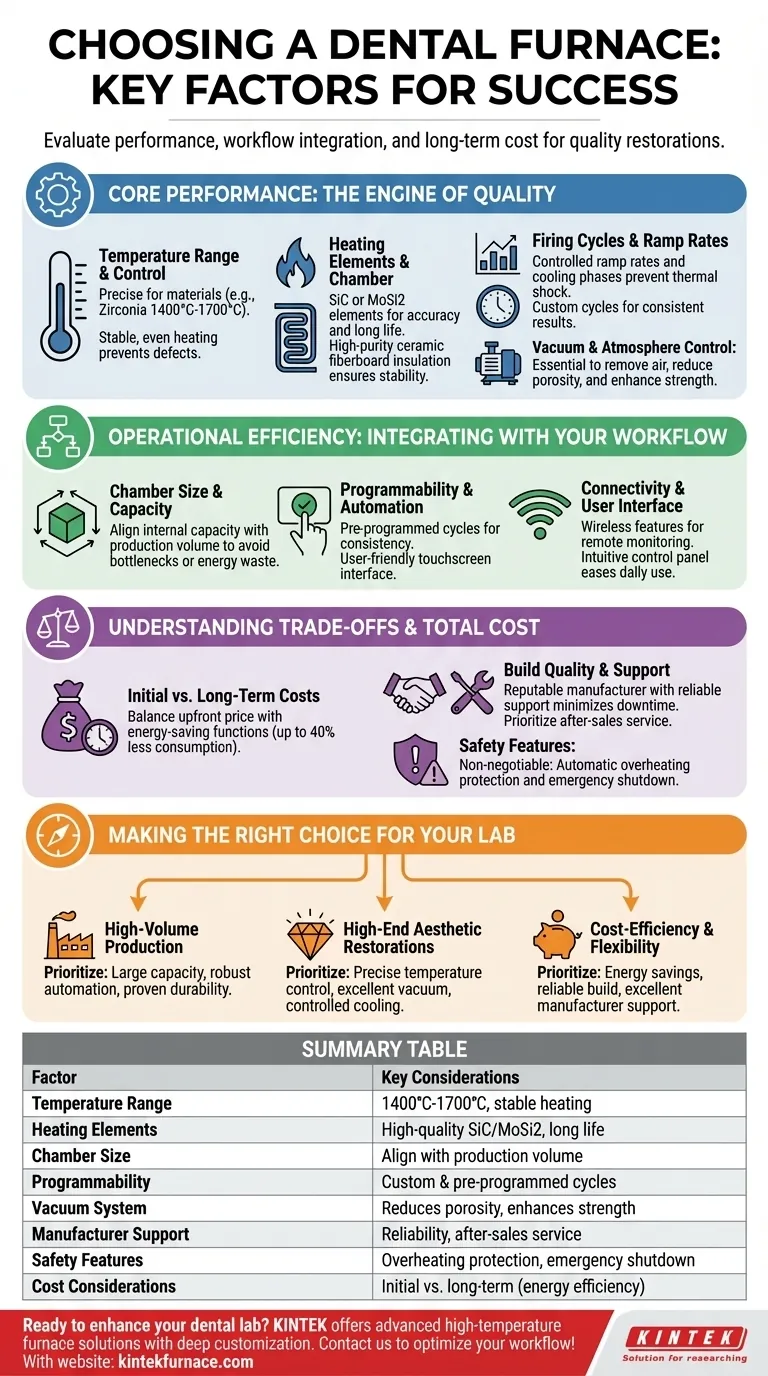

When choosing a dental furnace, you must evaluate a core set of factors related to performance, workflow integration, and long-term cost. Key considerations include the furnace's temperature range and control, the quality of its heating elements, its chamber size, its programmability, and the reliability of the manufacturer. Making the right choice is critical for ensuring the quality of your restorations and the efficiency of your lab.

The selection process for a dental furnace is not about finding the "best" one, but about identifying the right tool for your specific needs. The ideal furnace is one that aligns perfectly with your primary materials, daily workload, and standards for aesthetic precision.

Core Performance: The Engine of Quality Restorations

The technical capabilities of a furnace directly determine the quality, durability, and aesthetics of the final restoration. These are the non-negotiable performance metrics you must evaluate first.

Temperature Range and Precision Control

The furnace must be able to reach and maintain the precise temperatures required for the materials you use. For materials like zirconia, this often means a range of 1400°C to 1700°C.

Even more important than the maximum temperature is the furnace's ability to maintain a stable and evenly distributed temperature throughout the chamber. Inconsistent heating leads to weak or warped restorations.

Heating Elements and Chamber Construction

The heating elements are the heart of the furnace. High-quality elements made from silicon carbide (SiC) or molybdenum disilicide (MoSi2) offer better temperature accuracy and a significantly longer service life.

Look for durable chamber insulation, such as high-purity ceramic fiberboard, which ensures stable temperatures and contributes to energy efficiency.

Firing Cycles and Ramp Rates

Ramp rate refers to how quickly the furnace heats up and cools down. While faster cycles can increase throughput, a controlled cooling phase is critical to prevent thermal shock, which can cause cracks and defects in the ceramic.

The ability to program custom firing cycles allows you to perfectly match the parameters to the specific requirements of different materials, ensuring consistent and predictable results.

Vacuum and Atmosphere Control

For many ceramic materials, a vacuum pump is essential. It removes air from the firing chamber, which reduces porosity and creates a denser, stronger, and more translucent final restoration. A reliable vacuum system is a hallmark of a high-quality furnace.

Operational Efficiency: Integrating with Your Workflow

A furnace's performance specifications are only part of the story. It must also fit seamlessly into your daily operations to maximize productivity and ease of use.

Chamber Size and Capacity

The furnace's internal capacity must align with your lab's production volume. A chamber that is too small will create a bottleneck, while an oversized one can be inefficient in terms of energy consumption for smaller batches.

Programmability and Automation

Modern furnaces feature pre-programmed cycles for common materials, which simplifies operation and ensures consistency. A user-friendly touchscreen interface reduces the learning curve and minimizes the risk of operator error.

Connectivity and User Interface

Advanced features like wireless connectivity allow for remote monitoring of firing cycles, providing flexibility and peace of mind. An intuitive, easy-to-navigate control panel is crucial for efficient day-to-day use.

Understanding the Trade-offs and Total Cost

A smart investment considers more than just the initial purchase price. You must weigh upfront costs against long-term operational expenses and potential risks.

Initial Investment vs. Long-Term Operating Costs

Some furnaces are equipped with energy-saving functions that can reduce electricity consumption by up to 40%. While these models may have a higher initial cost, they can deliver significant savings over the life of the unit.

Build Quality and Manufacturer Support

Investing in a furnace from a reputable manufacturer with a strong record of reliability is paramount. The hidden cost of equipment downtime far outweighs any initial savings from a cheaper, less reliable unit.

Crucially, evaluate the quality of the manufacturer's after-sales service and technical support. When issues arise, prompt and effective support is invaluable.

Safety Features as a Non-Negotiable

Ensure any furnace you consider has essential safety features, such as automatic overheating protection and emergency shutdown capabilities. These features protect your staff, your facility, and your investment.

Making the Right Choice for Your Lab

Your final decision should be guided by your primary business objectives. Use these guidelines to prioritize the features that matter most to you.

- If your primary focus is high-volume production: Prioritize a large chamber capacity, robust automation features, and proven durability to handle a heavy workload.

- If your primary focus is high-end aesthetic restorations: Prioritize precise temperature control, an excellent vacuum system, and controlled cooling cycles for superior material properties.

- If your primary focus is cost-efficiency and flexibility: Prioritize a furnace with strong energy-saving features, a reliable build, and excellent manufacturer support to minimize long-term expenses.

By thoroughly analyzing your needs against these key factors, you can make an informed decision that will serve as a valuable asset for your practice for years to come.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature Range | 1400°C to 1700°C for materials like zirconia, stable and even heating |

| Heating Elements | High-quality SiC or MoSi2 for accuracy and long life |

| Chamber Size | Align with production volume to avoid bottlenecks or inefficiency |

| Programmability | Custom firing cycles, pre-programmed options for consistency |

| Vacuum System | Essential for reducing porosity and enhancing strength |

| Manufacturer Support | Reliability, after-sales service, and technical support |

| Safety Features | Overheating protection and emergency shutdown |

| Cost Considerations | Initial investment vs. long-term savings from energy efficiency |

Ready to enhance your dental lab's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you focus on high-volume production, high-end aesthetics, or cost-efficiency, our furnaces ensure superior temperature control, reliability, and long-term value. Contact us today to discuss how we can optimize your workflow and deliver exceptional results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations