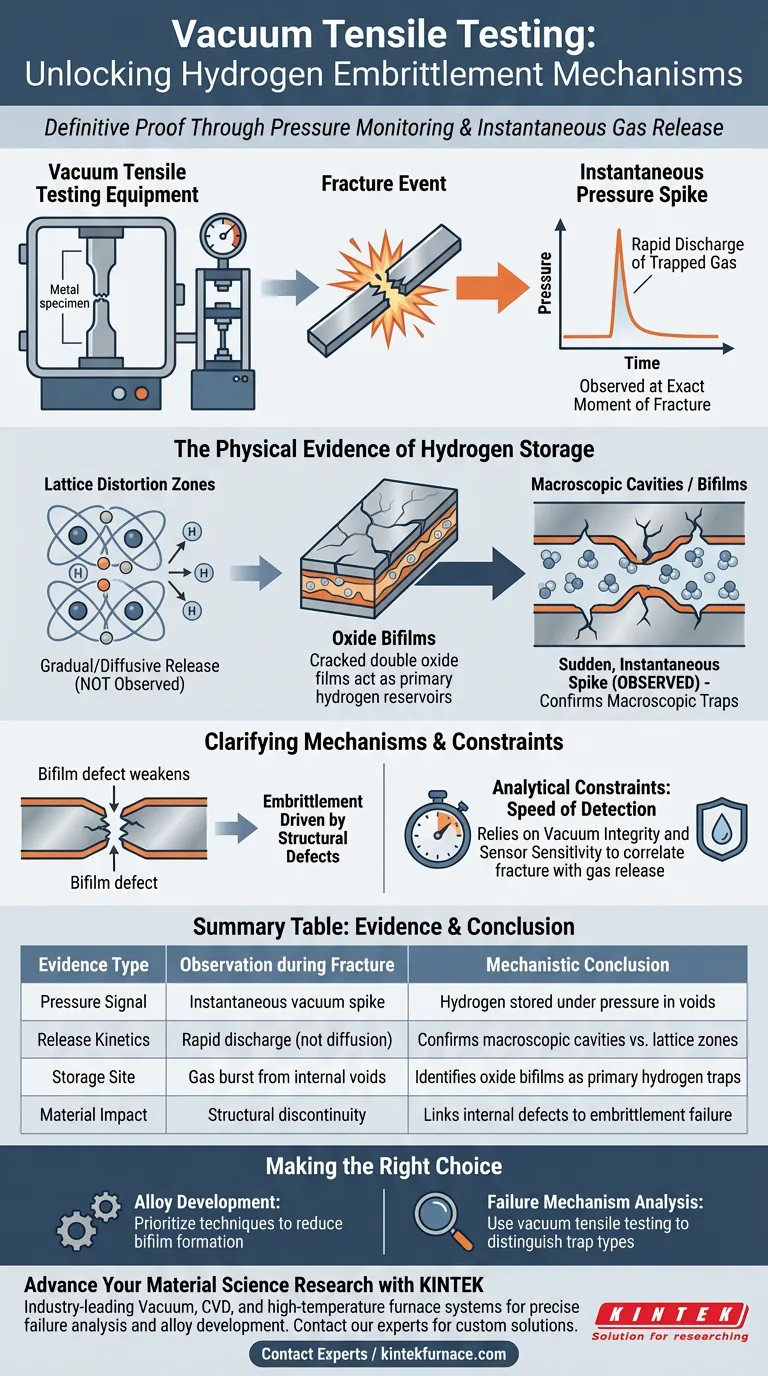

Vacuum tensile testing equipment provides definitive evidence of hydrogen storage mechanisms through pressure monitoring. Specifically, researchers observe a sudden, instantaneous spike in the vacuum chamber pressure at the exact moment the metal specimen fractures. This distinct physical signal serves as experimental proof of how and where hydrogen is retained within the metal's structure.

By capturing the instantaneous release of gas upon fracture, this testing method proves that hydrogen is accumulated in macroscopic cavities, such as bifilms, rather than simply existing within atomic lattice distortions.

The Physical Evidence of Hydrogen Storage

The Phenomenon of Instantaneous Release

The primary evidence provided by vacuum tensile testing is the timing and nature of the pressure change. When the alloy fractures, the equipment records an immediate surge in chamber pressure.

This suggests that the hydrogen was not slowly diffusing out of the material. Instead, it indicates a rapid discharge of a significantly larger volume of gas that was trapped under pressure.

Distinguishing Storage Locations

This evidence allows researchers to differentiate between microscopic and macroscopic hydrogen storage.

If hydrogen were solely located in lattice distortion zones, the release would likely be gradual or diffusive. The sudden pressure spike confirms the presence of macroscopic cavities—physical voids inside the metal that hold pockets of gas.

The Role of Oxide Bifilms

Identifying the Trap

The data specifically points to cracked double oxide films, known as bifilms, as the primary "traps" for hydrogen.

These bifilms create internal discontinuities within the metal. The vacuum test proves these films act as reservoirs, storing hydrogen gas until the material fails.

Clarifying Embrittlement Mechanisms

By identifying bifilms as the core storage site, the equipment clarifies the mechanism of embrittlement.

It moves the understanding away from purely atomic-level interactions to structural defects. The hydrogen trapped in these films weakens the material, facilitating the fracture that releases the gas.

Understanding the Analytical Constraints

Specificity of the Signal

It is important to note that this evidence relies heavily on the speed of detection. The distinct advantage of this method is its ability to correlate the exact moment of structural failure with gas release.

Without the vacuum environment, this release would be undetectable against atmospheric pressure. Therefore, the validity of this evidence depends entirely on the integrity of the vacuum seal and the sensitivity of the pressure sensors.

Making the Right Choice for Your Research

To effectively utilize these findings in material science or failure analysis, consider the following applications:

- If your primary focus is Alloy Development: Prioritize casting and processing techniques that reduce the formation of double oxide films (bifilms) to minimize hydrogen trap sites.

- If your primary focus is Failure Mechanism Analysis: Utilize vacuum tensile testing to distinguish whether hydrogen embrittlement is driven by lattice diffusion or macroscopic gas pockets.

The sudden release of pressure in a vacuum confirms that structural defects, not just atomic lattice issues, are the critical reservoirs for hydrogen in aluminum alloys.

Summary Table:

| Evidence Type | Observation during Fracture | Mechanistic Conclusion |

|---|---|---|

| Pressure Signal | Instantaneous vacuum spike | Hydrogen is stored under pressure in voids |

| Release Kinetics | Rapid discharge (not diffusion) | Confirms macroscopic cavities vs. lattice zones |

| Storage Site | Gas burst from internal voids | Identifies oxide bifilms as primary hydrogen traps |

| Material Impact | Structural discontinuity | Links internal defects to embrittlement failure |

Advance Your Material Science Research with KINTEK

Identifying the root cause of hydrogen embrittlement requires precision and high-performance testing environments. KINTEK provides industry-leading, customizable Vacuum, CVD, and high-temperature furnace systems designed to meet the rigorous demands of material failure analysis and alloy development.

Backed by expert R&D and world-class manufacturing, our equipment empowers researchers to capture critical data—from gas release signals to structural transitions. Whether you need a standard Muffle furnace or a specialized Vacuum system, our solutions are tailored to your unique laboratory needs.

Ready to eliminate structural defects and enhance your alloy performance? Contact our experts today to find your custom solution.

Visual Guide

References

- Time-Dependent Failure Mechanisms of Metals; The Role of Precipitation Cleavage. DOI: 10.20944/preprints202508.2134.v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are some common industrial applications of vacuum furnaces? Unlock Purity and Performance in Your Processes

- What are the advantages of conducting heat treatment in a vacuum environment? Achieve Superior Material Control and Quality

- Can horizontal vacuum furnaces be customized for specific needs? Tailor Your Thermal Process for Optimal Results

- What types of materials are suitable for vacuum sintering furnaces? Ideal for Reactive Metals and High-Purity Applications

- What role does a high-temperature vacuum furnace play in the desilication of biomass? Achieve Ultra-High Purity Carbon

- What are the main features and advantages of a vacuum heat treatment furnace? Achieve Superior Material Quality & Efficiency

- How does a vacuum furnace differ from conventional heat treatment configurations? Discover Key Benefits for Superior Material Quality

- How do vacuum brazing furnaces eliminate part distortion? Achieve Perfect Dimensional Accuracy