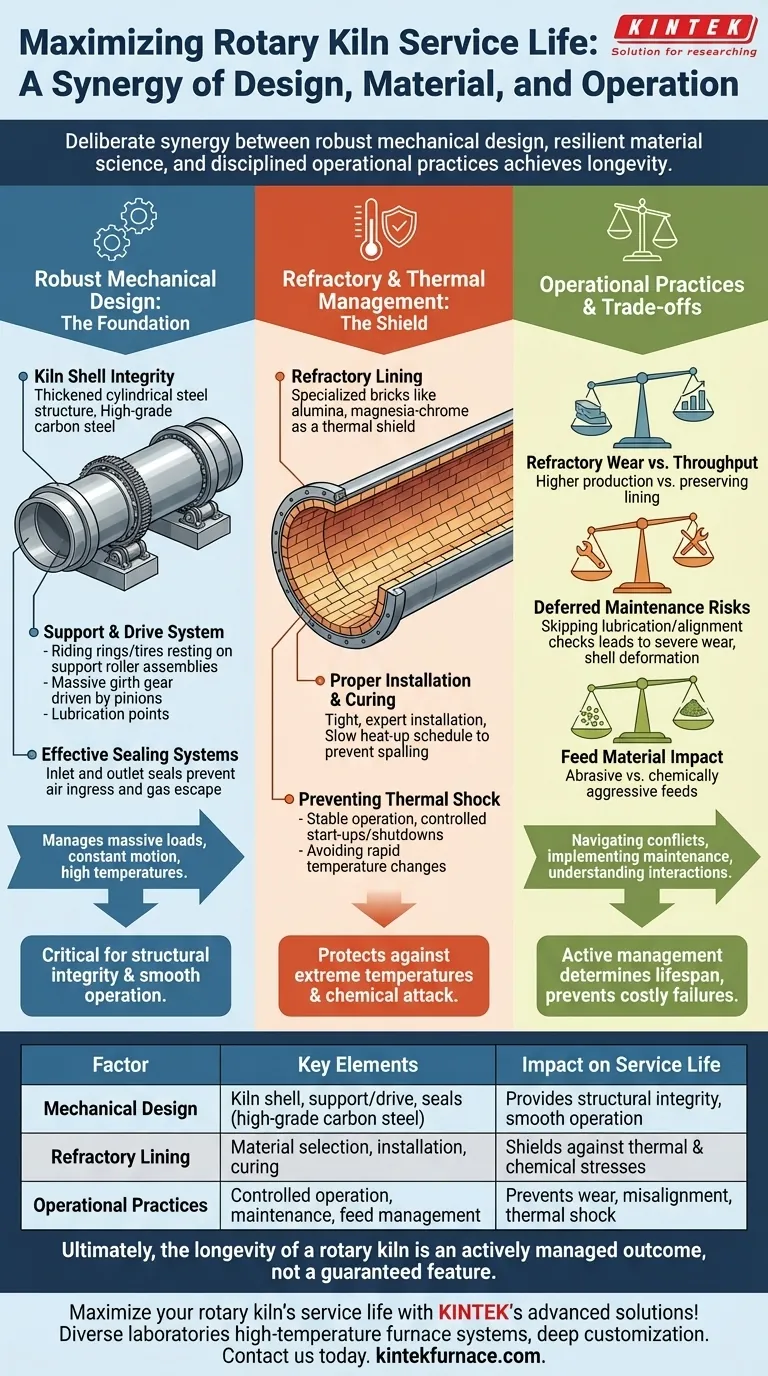

The long service life of a rotary kiln is not accidental; it is the result of a deliberate synergy between robust mechanical design, resilient material science, and disciplined operational practices. While high-quality construction forms the foundation, it is the ongoing maintenance and controlled operation that ultimately determine whether a kiln achieves a lifespan measured in decades.

A rotary kiln's longevity is not a static feature determined at the time of manufacture. It is a dynamic outcome of the constant battle against thermal, chemical, and mechanical stresses, a battle won through superior design, diligent maintenance, and intelligent operation.

The Foundation: Robust Mechanical Design

The core structure of the kiln is its first line of defense against the immense physical forces it endures. Every component is designed to manage massive loads and constant motion.

Kiln Shell Integrity

The kiln shell is the primary cylindrical steel structure. Its thickness and material grade (typically high-quality carbon steel) are engineered to withstand the huge mechanical stresses from the weight of the refractory and product load, all while enduring high temperatures.

The Support and Drive System

The immense weight of the kiln is transferred through steel riding rings (or "tires") onto support roller assemblies. The quality of these components and their bearings is critical for smooth rotation and load distribution.

The kiln is turned by a massive girth gear driven by one or more pinions. The precise alignment and constant lubrication of this drive train are paramount to preventing premature wear and catastrophic gear failure.

Effective Sealing Systems

Seals at the kiln's feed and discharge ends are crucial. They prevent cold air from entering the kiln (air ingress) and hot gases from escaping. This maintains thermal efficiency, protects ancillary equipment, and ensures a stable process environment, which in turn reduces stress on the entire system.

The Shield: Refractory and Thermal Management

Inside the steel shell, the refractory lining is the most critical element for thermal protection and, consequently, for the kiln's long-term survival.

The Role of the Refractory Lining

The refractory lining, typically made of specialized bricks (e.g., alumina, magnesia-chrome), acts as a thermal shield. It protects the steel shell from extreme process temperatures that would otherwise cause it to weaken and fail.

The choice of refractory material depends entirely on the specific process, considering factors like operating temperature, chemical attack from the product, and abrasion.

Proper Installation and Curing

Even the highest quality refractory bricks will fail prematurely if not installed correctly. A tight, expert installation followed by a slow, controlled heat-up schedule (curing) is essential to drive out moisture and allow the lining to set properly, preventing spalling and cracking.

Preventing Thermal Shock

Rapid changes in temperature create immense stress in the refractory, a phenomenon known as thermal shock. Stable, controlled operation and planned, slow shutdowns and start-ups are the most effective ways to prevent the cracking and failure that result from this stress.

Understanding the Trade-offs and Common Failure Points

Achieving maximum service life requires navigating operational and maintenance trade-offs. Ignoring them is the fastest path to costly, premature failure.

Refractory Wear vs. Throughput

There is often a direct conflict between maximizing production and preserving the refractory. Pushing for higher throughput can require higher temperatures or different feed chemistry, both of which can drastically accelerate wear on the refractory lining and increase the frequency of expensive relining projects.

The True Cost of Deferred Maintenance

Postponing routine tasks like lubrication or alignment checks is a critical error. A misaligned kiln concentrates massive loads onto small sections of the rollers and riding rings, leading to severe localized wear. This eventually causes shell deformation ("cranking") and failures that are orders of magnitude more expensive than the maintenance that was skipped.

The Impact of Feed Material

The chemical and physical properties of the material being processed have a direct impact on kiln life. Highly abrasive feeds will physically wear down the refractory, while chemically aggressive materials will corrode it. Understanding this interaction is key to selecting the right refractory and predicting its lifespan.

Making the Right Choice for Your Goal

Your operational priorities will dictate where you focus your resources to maximize the kiln's service life.

- If your primary focus is procurement and initial investment: Scrutinize the shell material specifications, the design of the support and drive systems, and the quality of the proposed refractory lining.

- If your primary focus is maximizing operational lifespan: Implement and enforce a rigorous preventative maintenance schedule centered on kiln alignment, lubrication, and frequent inspections of the refractory and seals.

- If your primary focus is optimizing production: Invest in advanced monitoring systems, such as infrared shell scanners, to provide real-time data on the kiln's thermal profile, allowing you to catch and correct damaging hot spots before they destroy the refractory.

Ultimately, the longevity of a rotary kiln is an actively managed outcome, not a guaranteed feature.

Summary Table:

| Factor | Key Elements | Impact on Service Life |

|---|---|---|

| Mechanical Design | Kiln shell, support/drive system, seals | Provides structural integrity and smooth operation |

| Refractory Lining | Material selection, installation, curing | Shields against thermal and chemical stresses |

| Operational Practices | Controlled operation, maintenance, feed management | Prevents wear, misalignment, and thermal shock |

| Maintenance | Alignment checks, lubrication, inspections | Avoids costly failures and extends lifespan |

Maximize your rotary kiln's service life with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing durability and efficiency. Contact us today to discuss how we can support your goals with reliable, long-lasting equipment!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing