Crucible size selection is dictated by two primary constraints: the physical dimensions of your sample and the internal, usable space within your muffle furnace's chamber. A correctly sized crucible must be large enough to safely contain the sample as it heats—potentially expanding or off-gassing—while being small enough to allow for proper air circulation and uniform heating inside the furnace.

The optimal crucible is not simply one that "fits." It is a component chosen to create a balanced thermal system, ensuring the sample is heated uniformly without impeding furnace performance or creating a safety risk.

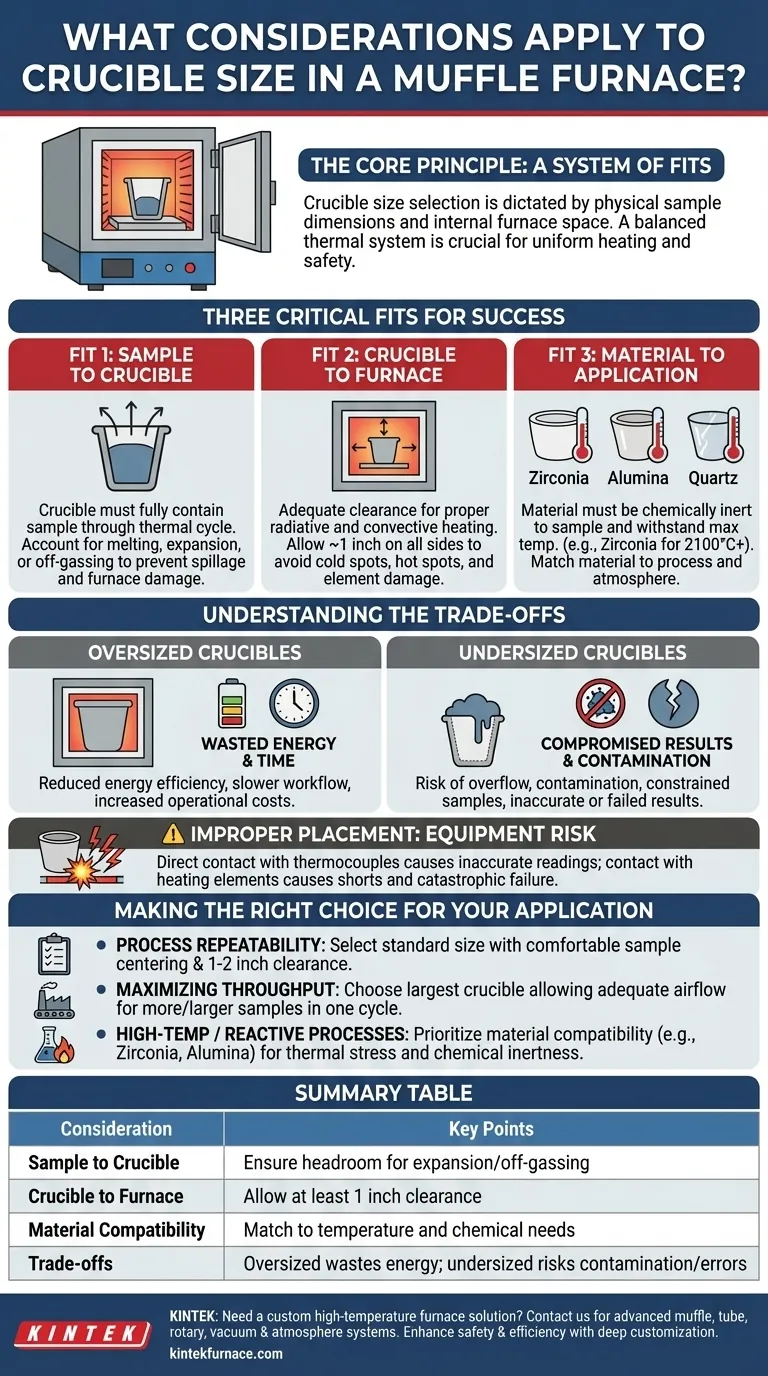

The Core Principle: A System of Fits

Thinking of selection as a series of "fits" clarifies the decision process. The crucible is the interface between your sample and the furnace, and all three parts must be compatible to achieve a successful outcome.

Fit 1: The Sample to the Crucible

The most immediate consideration is the relationship between the sample and the crucible. The crucible must fully contain the sample throughout the entire thermal cycle.

This means accounting for any changes in the sample's state. Materials that melt, expand, or release gases require a crucible with significant headroom to prevent spillage, which can damage the furnace floor and heating elements.

Fit 2: The Crucible to the Furnace Chamber

A crucible that is technically small enough to slide into the furnace is not necessarily the right size. For proper radiative and convective heating, there must be adequate clearance on all sides.

Placing a crucible too close to the chamber walls or heating elements creates cold spots on the sample and hot spots on the furnace components. This leads to non-uniform processing and significantly increases the risk of damaging the heating elements through direct contact or localized overheating. A general rule is to allow for at least one inch of clearance in all directions.

Fit 3: The Material to the Application

The crucible's material is as critical as its size. The chosen material must be chemically inert to your sample and capable of withstanding the furnace's maximum operating temperature without degrading.

For example, the references note that Zirconia crucibles are suitable for extremely high temperatures (2100°C and above). Other common materials like alumina, quartz, or graphite have different temperature limits and chemical compatibilities that must be matched to your specific process and furnace atmosphere.

Understanding the Trade-offs

Choosing the wrong size is not just an inconvenience; it has direct consequences for your results, your energy costs, and the lifespan of your equipment.

Oversized Crucibles: Wasted Energy

A crucible that is excessively large for the sample requires more energy and time to reach the target temperature. This reduces the furnace's overall energy efficiency and slows down your workflow, increasing operational costs over time.

Undersized Crucibles: Compromised Results

A crucible that is too small risks sample overflow and contamination of the furnace chamber. More subtly, it can physically constrain a sample that needs to expand or react, altering the outcome of the process and leading to inaccurate or failed results.

Improper Placement: Equipment Risk

Even a perfectly sized crucible can cause damage if placed incorrectly. Allowing the crucible to make direct contact with the furnace's thermocouple can lead to inaccurate temperature readings, while contact with a heating element can cause an electrical short and catastrophic failure.

Making the Right Choice for Your Application

Use these guidelines to select the best crucible based on your primary objective.

- If your primary focus is process repeatability: Select a standard crucible size that comfortably centers your sample and allows for at least 1-2 inches of clearance on all sides within the furnace.

- If your primary focus is maximizing throughput: Choose the largest crucible that still maintains adequate clearance for airflow, allowing you to process larger or more numerous samples safely in a single cycle.

- If your primary focus is high-temperature or reactive processes: Prioritize the crucible's material composition first (e.g., Zirconia, Alumina, Quartz), ensuring it can handle the thermal stress and will not react with your sample or atmosphere.

By viewing the crucible not as an isolated container but as a critical link between your sample and your furnace, you ensure precise, safe, and efficient results.

Summary Table:

| Consideration | Key Points |

|---|---|

| Sample to Crucible Fit | Ensure crucible contains sample with headroom for expansion/off-gassing |

| Crucible to Furnace Fit | Allow at least 1 inch clearance for uniform heating and safety |

| Material Compatibility | Match crucible material (e.g., Zirconia, Alumina) to temperature and chemical needs |

| Trade-offs | Oversized wastes energy; undersized risks contamination and inaccurate results |

Need a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental requirements, enhancing safety and efficiency. Contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production