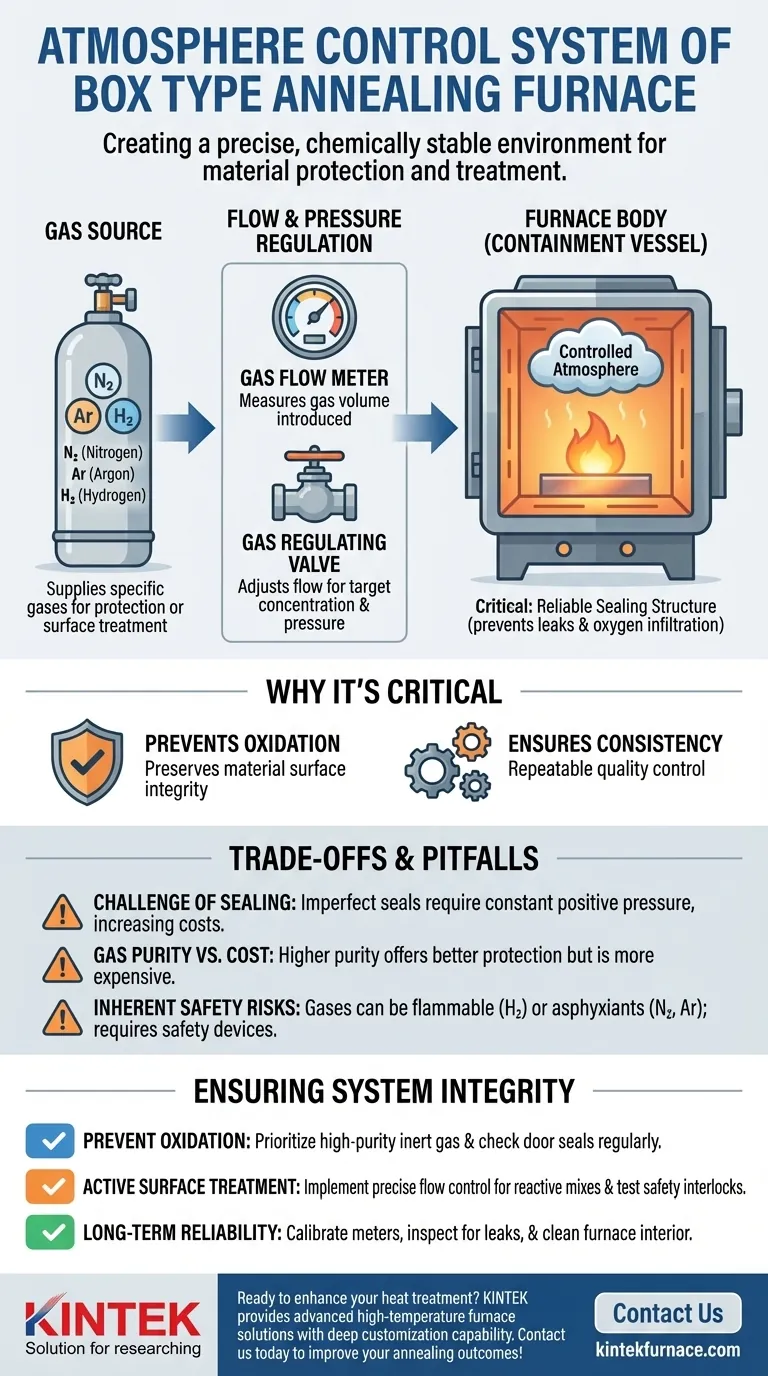

At its core, an atmosphere control system for a box-type annealing furnace is composed of four main elements. These are the gas source, a gas flow meter, a gas regulating valve, and the furnace body itself, which contains the controlled environment. Together, these components work to introduce specific gases and maintain a precise atmosphere to protect or treat the workpiece during the annealing cycle.

The purpose of an atmosphere control system is not simply to fill a furnace with gas. Its true function is to create and sustain a chemically stable environment, meticulously managing gas purity, flow, and pressure to prevent unwanted reactions like oxidation and ensure the material's surface integrity.

The Core Components of Atmosphere Control

To achieve a stable and protective environment, each part of the system must perform its function reliably. The system is a chain where the failure of one link compromises the entire process.

The Gas Source

The process begins with the gas source. This is the supply of the specific gas or gas mixture required for the annealing process.

The choice of gas depends entirely on the material being treated and the desired outcome. Common gases include inert options like nitrogen (N₂) and argon (Ar) to prevent oxidation, or reactive gases like hydrogen (H₂) and decomposed ammonia for surface reduction.

The Flow and Pressure Regulation System

This part of the system is the brain of the operation, dictating how much gas enters the furnace and when. It primarily consists of two devices.

The gas flow meter measures the volume of gas being introduced into the furnace. The gas regulating valve then adjusts this flow based on control system inputs to achieve and maintain the target concentration and positive pressure inside the furnace.

The Furnace Body as a Containment Vessel

While not an active control device, the furnace body is a critical component of the system. Its role is to contain the controlled atmosphere and isolate it from the ambient air outside.

The effectiveness of the entire system hinges on the integrity of the furnace chamber. A reliable sealing structure, especially around the furnace door, is essential to prevent atmosphere leakage and the infiltration of oxygen, which would undermine the process.

Why Precise Atmosphere Control is Critical

The complexity of this system is directly tied to the strict metallurgical requirements of the annealing process. Without it, the heat treatment would damage the material instead of improving it.

Preventing Oxidation and Decarburization

The primary goal is often protection. At high annealing temperatures, most metals will rapidly react with oxygen, forming a layer of scale or oxide on the surface. A controlled inert atmosphere displaces the oxygen, preserving the material's finish and properties.

Ensuring Process Consistency

By precisely managing the gas composition, flow rate, and pressure, the system ensures that every workpiece in a batch, and every batch over time, is treated under identical conditions. This repeatability is fundamental to modern quality control.

Understanding the Trade-offs and Pitfalls

A perfectly controlled atmosphere is the goal, but practical and safety considerations introduce necessary trade-offs.

The Challenge of Sealing

No seal is perfect. Furnace door gaskets and other connection points are common sources of leaks. Maintaining a slight positive pressure inside the furnace helps ensure that if a small leak exists, the controlled gas flows out rather than ambient air flowing in. This requires a constant, controlled gas flow, which has cost implications.

Gas Purity vs. Cost

Higher purity gases (e.g., 99.999% pure nitrogen) provide better protection but are significantly more expensive. For less sensitive applications, a lower purity or a blended gas might be sufficient, presenting a classic trade-off between process cost and final quality.

Inherent Safety Risks

The gases used can present serious hazards. Hydrogen is highly flammable, while nitrogen and argon are asphyxiants. Therefore, the atmosphere control system must be integrated with robust safety devices, such as overpressure relief valves, leak detectors, and alarms that can shut the system down in an emergency.

How to Ensure System Integrity

Your focus should be on maintaining the system to consistently deliver the desired outcome, whether it's protection, reaction, or long-term reliability.

- If your primary focus is preventing surface oxidation: Prioritize a high-purity inert gas source (nitrogen or argon) and perform regular checks on the furnace door seal integrity.

- If your primary focus is active surface treatment: Implement a highly precise flow control system for your reactive gas mix (e.g., H₂/N₂) and ensure all safety interlocks and alarms are tested and fully functional.

- If your primary focus is long-term reliability: Institute a strict maintenance schedule that includes calibrating flow meters, inspecting gas lines for leaks, and cleaning the furnace interior to remove contaminants.

Ultimately, viewing the atmosphere control system as an integrated whole is the key to achieving consistent, high-quality heat treatment results.

Summary Table:

| Component | Function |

|---|---|

| Gas Source | Supplies specific gases (e.g., N₂, Ar, H₂) for protection or surface treatment |

| Gas Flow Meter | Measures gas volume introduced into the furnace |

| Gas Regulating Valve | Adjusts gas flow to maintain target concentration and pressure |

| Furnace Body | Contains and seals the controlled atmosphere to prevent leaks and oxygen infiltration |

Ready to enhance your heat treatment processes with reliable atmosphere control? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can improve your annealing outcomes and ensure consistent quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment