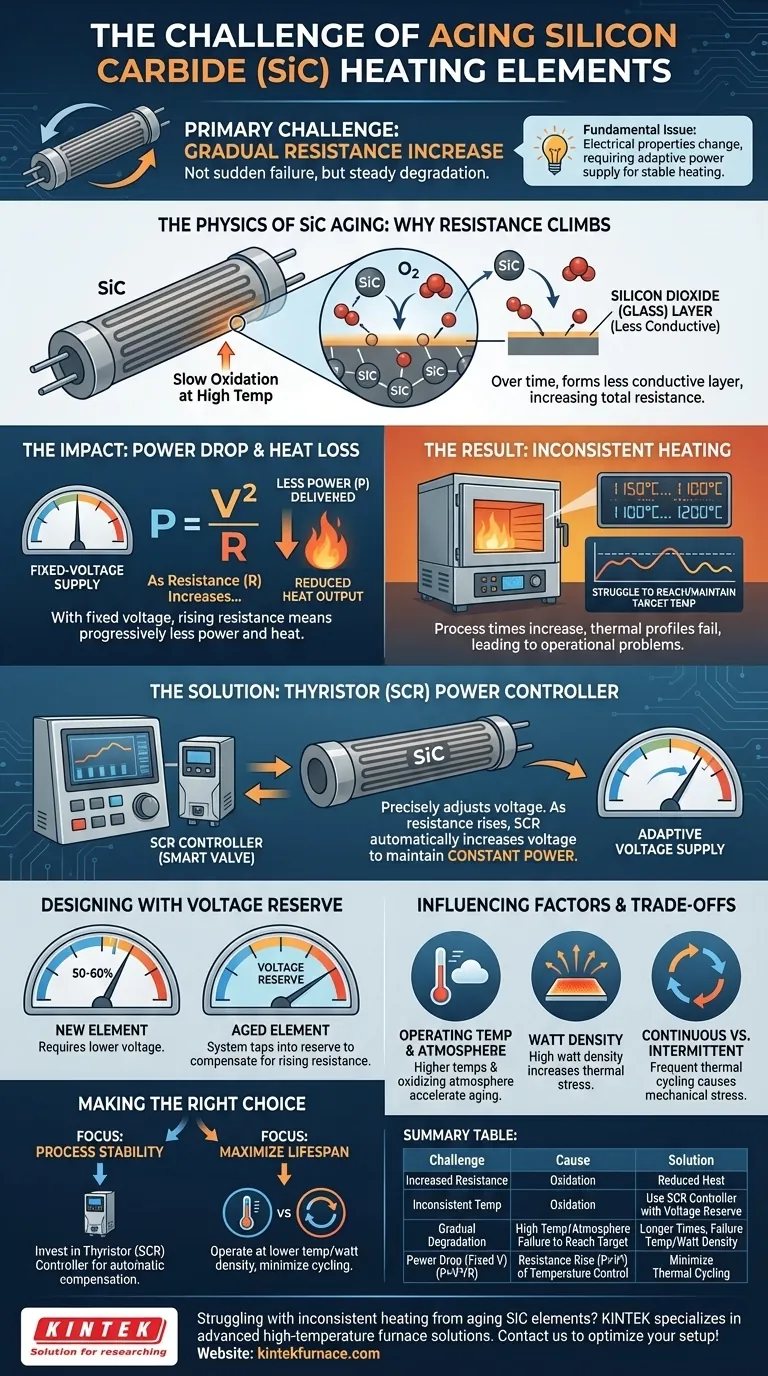

The primary challenge associated with aging Silicon Carbide (SiC) heating elements is that their electrical resistance steadily increases over time. This is not a sudden failure, but a gradual degradation that, if unmanaged, will cause a progressive drop in heat output and lead to inconsistent furnace temperatures.

The fundamental issue is not that the elements simply wear out, but that their electrical properties change. This rising resistance requires a power supply capable of compensating to maintain constant power and ensure stable, reliable heating throughout the element's lifespan.

The Physics of SiC Aging: Increased Resistance

Why Resistance Increases

The increase in resistance is a natural consequence of the material's slow oxidation at high operating temperatures. The silicon carbide reacts with oxygen in the furnace atmosphere to form a thin layer of silicon dioxide (glass), which is less electrically conductive.

Over hundreds or thousands of hours, this process gradually changes the element's bulk electrical characteristics, causing its total resistance to climb.

The Impact on Power Output

Heat is a direct result of electrical power. According to the foundational formula P = V²/R (Power = Voltage² / Resistance), power is inversely proportional to resistance when voltage is constant.

As the element's resistance (R) increases with age, a fixed-voltage power supply will deliver progressively less power (P). This directly translates to less heat generation.

The Result: Loss of Temperature Control

This power drop means the furnace will struggle to reach or maintain its target temperature. The process may take longer, or it may fail to achieve the required thermal profile altogether.

This "inconsistent heating" is the ultimate operational problem that stems from the element's natural aging process.

Managing the Aging Process

The Limitation of a Fixed Power Supply

A simple, fixed-voltage transformer is inadequate for SiC elements over the long term. It cannot adapt to the element's rising resistance, leading directly to the power drop described above.

The Solution: The Thyristor (SCR) Controller

Modern systems solve this problem using a thyristor-based power controller, often called an SCR (Silicon Controlled Rectifier).

An SCR acts like a sophisticated, high-speed valve for electricity. It can precisely adjust the voltage supplied to the heating element. As the element's resistance increases, the SCR automatically increases the voltage to maintain a constant power output, ensuring the heat remains stable.

Designing with Voltage Reserve

For this to work, the system must be designed with voltage reserve. A new SiC element might only require 50-60% of the power supply's maximum available voltage.

This leaves a "reserve" of voltage that the SCR controller can tap into over the element's life, increasing it as needed to compensate for the rising resistance.

Understanding the Trade-offs and Influencing Factors

Operating Temperature and Atmosphere

The rate of aging is not fixed. It is accelerated by higher operating temperatures and oxidizing atmospheres, which speed up the formation of silicon dioxide.

Watt Density

Watt density is the amount of power radiated per unit of the element's surface area. Running elements at a very high watt density puts more thermal stress on the material, shortening its effective service life.

Continuous vs. Intermittent Use

Frequent thermal cycling (heating and cooling) is more damaging to SiC elements than continuous operation. The expansion and contraction create mechanical stress that can exacerbate the aging process and lead to premature failure.

Making the Right Choice for Your Goal

To properly manage your SiC heating elements, you must align your operational strategy with your primary objective.

- If your primary focus is process stability and tight temperature control: Invest in a high-quality, phase-angle fired SCR power controller designed to automatically compensate for element aging.

- If your primary focus is maximizing element lifespan: Operate at the lowest effective temperature and watt density for your process and minimize unnecessary thermal cycling.

Understanding and actively managing this aging characteristic transforms it from a problem into a predictable aspect of furnace maintenance.

Summary Table:

| Challenge | Cause | Impact | Solution |

|---|---|---|---|

| Increased electrical resistance | Oxidation forming silicon dioxide layer | Reduced heat output, inconsistent temperatures | Use thyristor (SCR) controller with voltage reserve |

| Gradual degradation over time | High operating temperatures, oxidizing atmospheres | Longer process times, failure to reach target temperature | Operate at lower temperatures and watt density |

| Power drop with fixed voltage | Resistance rise per P = V²/R formula | Loss of temperature control | Minimize thermal cycling for extended lifespan |

Struggling with inconsistent heating from aging SiC elements? KINTEK specializes in advanced high-temperature furnace solutions tailored for diverse laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Ensure stable, reliable performance—contact us today to discuss how we can optimize your furnace setup!

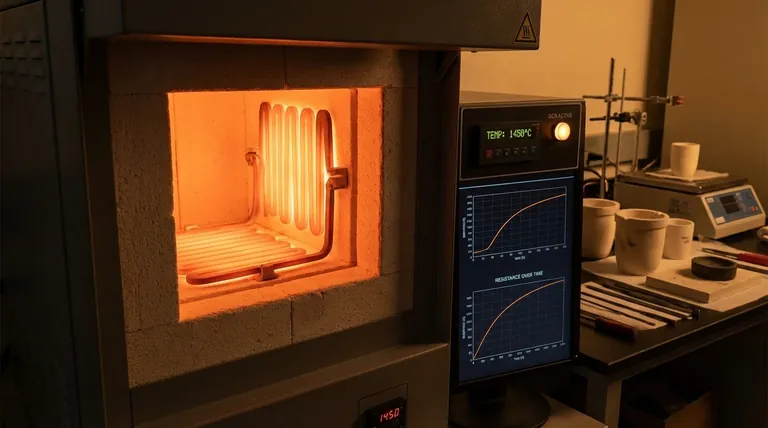

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer