At their core, a box furnace and an atmosphere furnace are distinguished by the environment they create. A box furnace operates in natural air, making it a simple heating chamber for general-purpose applications. An atmosphere furnace, however, is a specialized tool that allows you to replace the air with a precisely controlled gas, enabling advanced processes and protecting sensitive materials from oxidation.

The fundamental choice is not about which furnace is superior, but about the level of environmental control your process requires. A box furnace provides heat, while an atmosphere furnace provides heat within a controlled chemical environment.

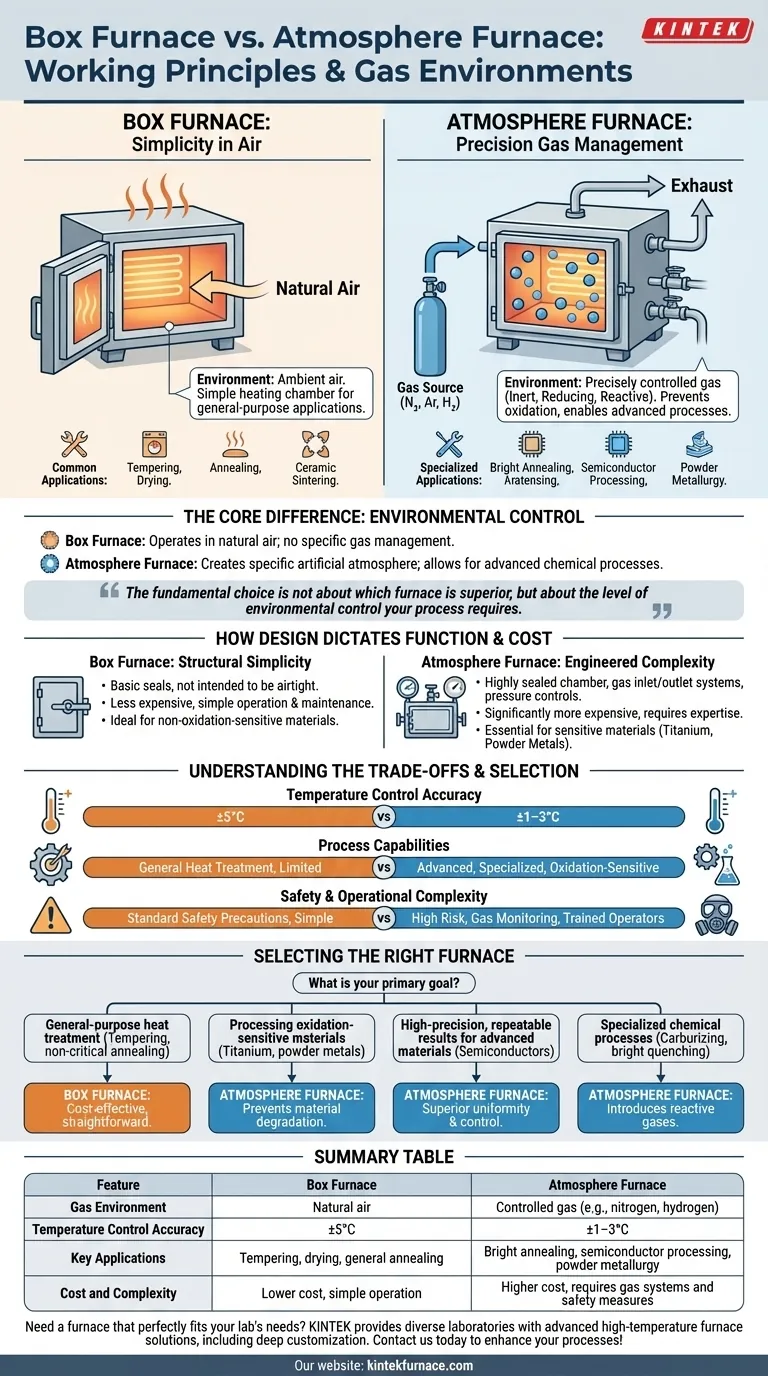

The Core Difference: Environmental Control

The defining characteristic that separates these two furnaces is their ability to manage the gas composition inside the heating chamber. This single difference dictates their design, application, and complexity.

The Box Furnace: Simplicity in Air

A standard box furnace is essentially a high-temperature oven. Its internal environment is the ambient air that was trapped inside when the door was closed.

These furnaces are ideal for conventional heat treatments where oxidation is either not a concern or is an accepted part of the process. This includes applications like tempering, drying, and certain types of annealing or ceramic sintering.

The Atmosphere Furnace: Precision Gas Management

An atmosphere furnace is engineered to create a specific, artificial atmosphere. It does this by purging the natural air and introducing a controlled gas or gas mixture.

The purpose is to prevent unwanted chemical reactions, primarily oxidation, or to intentionally induce a reaction. Protective gases like nitrogen or argon are inert, while active gases like hydrogen create a reducing environment. Other processes like carburizing use specific gas compositions to alter the surface chemistry of a material.

How Design Dictates Function and Cost

The need to control the internal atmosphere has profound implications for the furnace's construction, complexity, and ultimately, its price.

Structural Simplicity of Box Furnaces

Box furnaces feature a relatively simple design with basic seals on the furnace door. They are not intended to be perfectly airtight.

This straightforward construction makes them less expensive to manufacture, operate, and maintain, positioning them as a cost-effective solution for general-purpose heating.

The Engineered Complexity of Atmosphere Furnaces

To maintain a pure internal atmosphere, these furnaces require a highly sealed chamber. They must be equipped with dedicated gas inlet and outlet systems and pressure controls.

This engineering prevents gas leakage and contamination from outside air. The added complexity in manufacturing and control systems makes atmosphere furnaces significantly more expensive.

Understanding the Trade-offs

Choosing between these furnaces involves balancing process requirements against operational factors like precision, safety, and cost.

Process Capabilities and Limitations

A box furnace is a versatile workhorse for many common applications. However, it cannot be used for materials that are highly sensitive to oxygen, such as titanium alloys or many powder metals.

Atmosphere furnaces are purpose-built for these sensitive applications. They are essential for processes like bright annealing (which leaves no oxide layer), semiconductor component manufacturing, and modern powder metallurgy.

Precision and Uniformity

Box furnaces typically offer temperature control accuracy within ±5°C. This is sufficient for many bulk heat treatment processes.

Atmosphere furnaces provide superior temperature control, often with an accuracy of ±1–3°C. Many also include gas circulation systems that improve temperature uniformity throughout the chamber, ensuring consistent, repeatable results for high-value components.

Safety and Operational Complexity

A box furnace is simple to operate and requires only standard high-temperature safety precautions.

Atmosphere furnaces, especially those using flammable or explosive gases like hydrogen, present a much higher safety risk. They demand sophisticated gas monitoring systems, explosion-proof devices, and professionally trained operators, increasing the overall operational threshold.

Selecting the Right Furnace for Your Application

Your choice ultimately depends on the material you are processing and the outcome you need to achieve. Assess your primary goal to make a clear decision.

- If your primary focus is general-purpose heat treatment (like tempering or non-critical annealing): A box furnace is the most cost-effective and straightforward solution.

- If your primary focus is processing oxidation-sensitive materials (like titanium or powder metals): An atmosphere furnace is non-negotiable to prevent material degradation.

- If your primary focus is achieving high-precision, repeatable results for advanced materials (like semiconductors): The superior temperature uniformity and control of an atmosphere furnace are essential.

- If your primary focus is specialized chemical processes (like carburizing or bright quenching): You must use an atmosphere furnace to introduce and control the necessary reactive gases.

Ultimately, your decision is guided by matching the furnace's environmental capabilities to your material's specific processing requirements.

Summary Table:

| Feature | Box Furnace | Atmosphere Furnace |

|---|---|---|

| Gas Environment | Natural air | Controlled gas (e.g., nitrogen, hydrogen) |

| Temperature Control Accuracy | ±5°C | ±1–3°C |

| Key Applications | Tempering, drying, general annealing | Bright annealing, semiconductor processing, powder metallurgy |

| Cost and Complexity | Lower cost, simple operation | Higher cost, requires gas systems and safety measures |

Need a furnace that perfectly fits your lab's needs? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your processes with tailored furnace solutions!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality