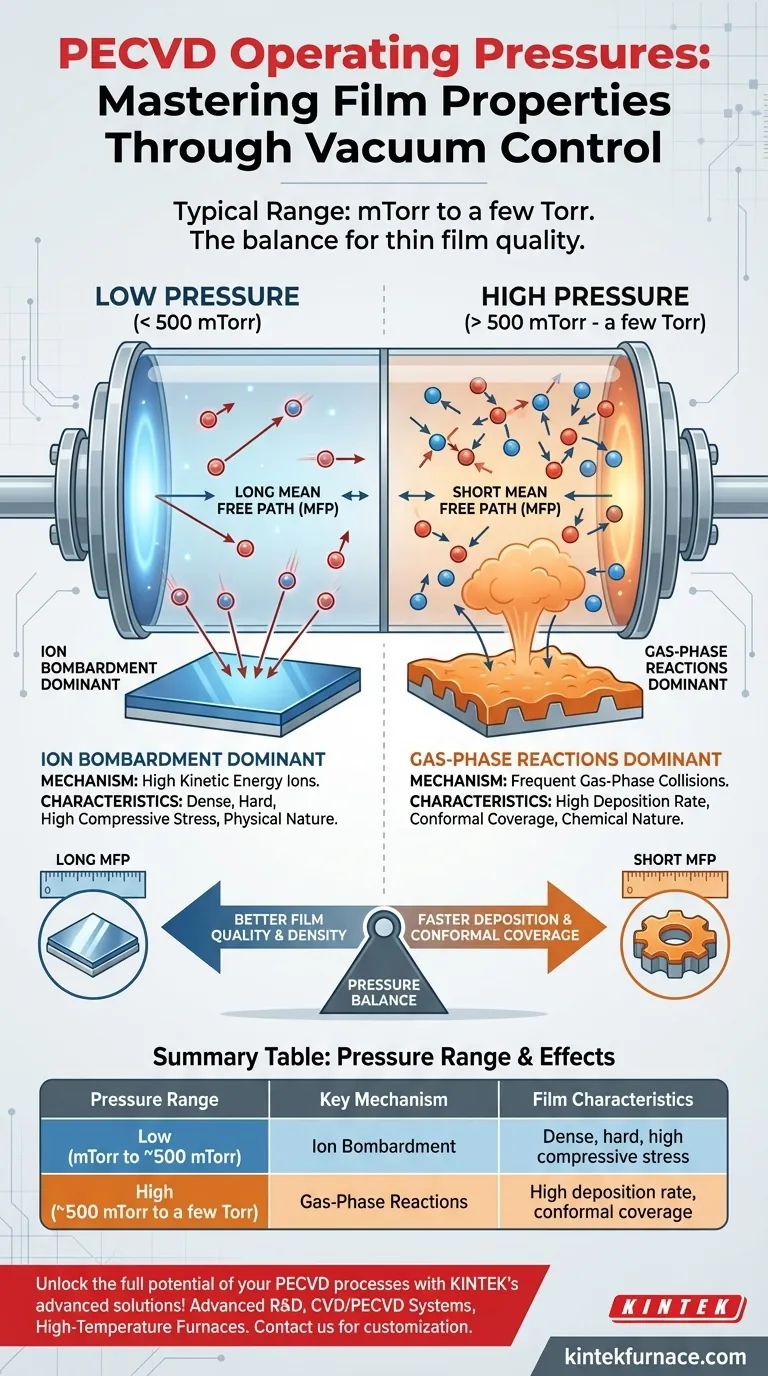

In short, the typical operating pressure for processing plasmas in Plasma-Enhanced Chemical Vapor Deposition (PECVD) ranges from a few millitorr (mTorr) to a few torr. This range represents the vacuum level inside the deposition chamber, which is a critical parameter for controlling the final properties of the thin film.

The choice of pressure is not arbitrary; it is a fundamental trade-off. Lower pressures promote energetic ion bombardment for creating dense films, while higher pressures encourage gas-phase chemical reactions needed for faster, more conformal coatings. Understanding this balance is the key to mastering the PECVD process.

The Role of Pressure in the PECVD Process

Pressure is one of the most influential variables in PECVD because it directly governs the behavior of gas molecules and the nature of the plasma itself. The entire process hinges on controlling the interactions between particles within the chamber.

Defining the Pressure Range

The standard PECVD process operates in a rough vacuum, typically between 10 mTorr and 5 Torr. For context, one Torr is approximately 1/760th of standard atmospheric pressure.

This range is the sweet spot that allows for the stable generation of a plasma without the extreme equipment demands of ultra-high vacuum systems.

The Concept of Mean Free Path (MFP)

The most important physical principle controlled by pressure is the mean free path (MFP). This is the average distance a gas particle (an atom, ion, or molecule) travels before colliding with another particle.

At low pressure, there are fewer gas molecules, so the MFP is long. Particles can travel across the chamber and accelerate to high energies before hitting the substrate.

At high pressure, the chamber is more crowded, so the MFP is short. Particles undergo many collisions, losing energy and reacting with each other in the gas phase before ever reaching the substrate.

How Pressure Impacts Film Deposition

The length of the mean free path directly dictates the primary mechanism of film deposition and, consequently, the material's final characteristics.

Low-Pressure Regimes (mTorr to ~500 mTorr)

Operating at lower pressures favors a process dominated by ion bombardment. With a long MFP, ions are accelerated by the plasma's electric field and strike the substrate with high kinetic energy.

This energetic bombardment transfers momentum to the growing film, resulting in materials that are typically denser, harder, and have higher compressive stress. The deposition is more "physical" in nature.

High-Pressure Regimes (~500 mTorr to a few Torr)

At higher pressures, the short MFP leads to frequent collisions in the gas phase. This environment promotes chemical reactions between the precursor gas molecules, creating the film-forming species before they reach the substrate.

This leads to a process that is more "chemical" in nature. It often results in higher deposition rates and better conformal coverage over complex, non-flat surfaces. However, the resulting films can be less dense or more porous.

Understanding the Trade-offs

Selecting the correct pressure is always a balance between competing factors. There is no single "best" pressure; there is only the best pressure for a specific application.

Deposition Rate vs. Film Quality

Higher pressures generally increase the concentration of reactive species, leading to a faster deposition rate. However, this speed can come at the cost of film quality, potentially reducing density and uniformity.

Ion Bombardment vs. Conformal Coverage

Low-pressure deposition is ideal for creating dense, robust films on flat surfaces. High-pressure deposition is superior for coating intricate topographies, as the chemical precursors can "stick" to all surfaces more evenly without being driven by line-of-sight ion bombardment.

A Note on Atmospheric Pressure

While the references note that some plasmas can operate at atmospheric pressure, this is highly specialized and not typical for thin-film PECVD. Controlling uniformity and preventing gas-phase particle formation (dust) becomes extremely challenging at such high pressures, requiring unique reactor designs like plasma jets.

Selecting the Right Pressure for Your Goal

Your choice of operating pressure should be dictated entirely by the desired properties of your final thin film.

- If your primary focus is a dense, hard, or stress-controlled film: Operate in the lower pressure range (e.g., < 500 mTorr) to leverage high-energy ion bombardment.

- If your primary focus is a high deposition rate or conformal coverage: Operate in the higher pressure range (e.g., > 500 mTorr to a few Torr) to promote gas-phase chemical reactions.

- If your primary focus is process optimization for a new material: Start in the middle of the range (~1 Torr) and adjust up or down based on film characterization to find the right balance.

Ultimately, pressure is the primary knob you can turn to tune your film's properties from being physically dominated to chemically dominated.

Summary Table:

| Pressure Range | Key Mechanism | Film Characteristics |

|---|---|---|

| Low (mTorr to ~500 mTorr) | Ion Bombardment | Dense, hard, high compressive stress |

| High (~500 mTorr to a few Torr) | Gas-Phase Reactions | High deposition rate, conformal coverage |

Unlock the full potential of your PECVD processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve optimal film properties and efficiency. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition