At its core, a three-zone split tube furnace is used for sophisticated thermal processes that require exceptional temperature uniformity and easy sample accessibility. These furnaces are the tool of choice for applications like chemical vapor deposition (CVD), the annealing of semiconductors, advanced materials testing, and the controlled sintering of ceramics, where both precision and convenience are paramount.

The key takeaway is not just what these furnaces are used for, but why. The "three-zone" design creates a perfectly uniform hot zone by using end zones to compensate for heat loss, while the "split-tube" design allows the chamber to open for easy loading of complex or delicate samples.

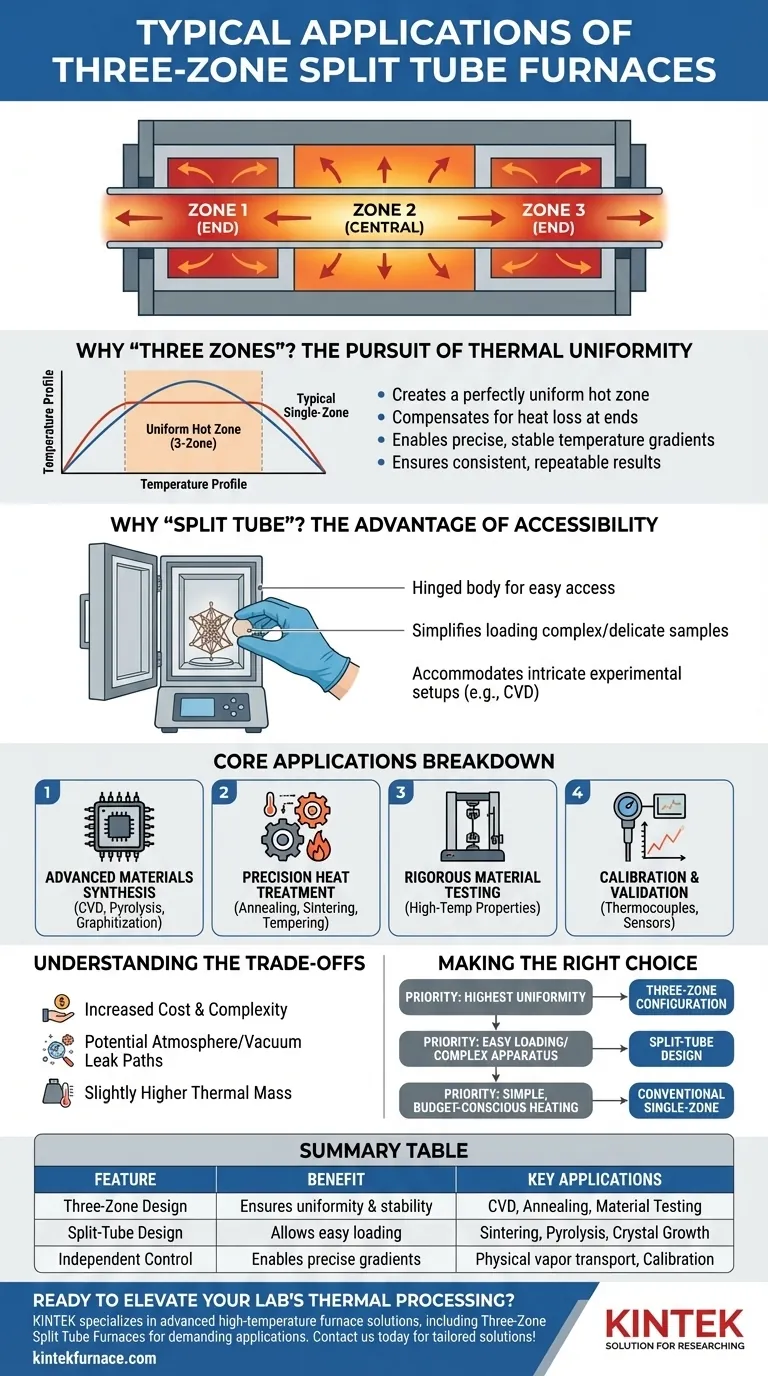

Why "Three Zones"? The Pursuit of Thermal Uniformity

A standard single-zone furnace is hottest in the middle and cooler at the ends due to natural heat loss. A three-zone design solves this fundamental problem.

How It Creates a Uniform Hot Zone

The furnace has three independently controlled heating areas: a large central zone and two smaller end zones.

By setting the end zones to a slightly higher temperature, you can create a power profile that actively counteracts the heat that would normally escape from the ends of the tube. This results in a much longer, flatter, and more uniform temperature profile across the central zone.

The Power of Controlled Gradients

While often used for uniformity, the three independent zones can also be programmed to create a precise, stable temperature gradient across the sample.

This capability is critical for specialized processes like physical vapor transport or certain types of crystal growth, where a controlled temperature difference drives the process.

Impact on Process Repeatability

For both R&D and manufacturing, process control is everything. The superior temperature stability of a three-zone furnace ensures that results are consistent and repeatable from one run to the next, which is essential for validating experiments or maintaining production quality.

Why "Split Tube"? The Advantage of Accessibility

The "split tube" feature refers to the furnace body being built on a hinge. This allows it to be opened vertically or horizontally, providing direct access to the work tube inside.

Simplifying Sample Handling

This design is ideal when working with samples that are difficult to insert into a long, solid tube. This includes delicate components, pre-assembled reactor setups, or objects with irregular shapes.

Instead of sliding the sample in from one end, you can place it directly into the work tube and then close the furnace around it.

Enabling Complex Experimental Setups

The split design makes it significantly easier to accommodate complex apparatus within the hot zone.

Applications like Chemical Vapor Deposition (CVD), which involve intricate gas delivery nozzles and substrate holders, benefit immensely from the ability to build the setup in an open tube before enclosing it within the furnace.

Core Applications Breakdown

The combination of thermal uniformity and accessibility makes these furnaces indispensable for several key applications.

Advanced Materials Synthesis

Processes like CVD, pyrolysis, and graphitization rely on precise temperature control to create thin films or transform materials. The furnace's uniformity ensures the resulting material has consistent properties, while the split design allows for the necessary complex gas-handling equipment.

Precision Heat Treatment

Applications like annealing, sintering, and tempering are performed to alter the microstructure of a material. A perfectly uniform hot zone ensures that the entire sample receives the exact same thermal treatment, preventing weak spots or inconsistent material properties.

Rigorous Material Testing and Calibration

When testing material properties at high temperatures (e.g., tensile strength) or calibrating temperature sensors like thermocouples, the sample must be held in a known, stable thermal environment. The certified uniformity of a three-zone furnace provides this reliable baseline.

Understanding the Trade-offs

While powerful, these furnaces are not the universal solution. Their specialized design comes with specific considerations.

Increased Cost and Complexity

A three-zone furnace requires three independent controllers and power circuits, making it more expensive and complex to operate than a single-zone model. The mechanical hinge system of a split tube also adds to the cost and mechanical complexity.

Atmosphere and Vacuum Sealing

While excellent seals are achievable, the presence of a split in the furnace body can present more potential leak paths than a solid furnace design. Achieving and maintaining a high-purity inert atmosphere or a deep vacuum can require more careful engineering of the end seals on the work tube.

Thermal Mass

The larger, more intricate heating element assembly of a three-zone furnace may result in a slightly higher thermal mass. This can lead to marginally slower heat-up and cool-down rates compared to a simpler, lower-mass single-zone furnace.

Making the Right Choice for Your Goal

The decision to use a three-zone split tube furnace should be driven by the specific demands of your process.

- If your primary focus is achieving the highest possible temperature uniformity over a defined sample length: The three-zone configuration is the critical feature you need.

- If your primary focus is processing samples that are difficult to load or require a complex apparatus inside the tube: The split-tube design is the most important advantage.

- If your primary focus is simple, budget-conscious heating where absolute uniformity is not critical: A more conventional single-zone, non-split tube furnace is likely a more suitable and cost-effective choice.

Ultimately, selecting a three-zone split tube furnace is a decision to prioritize precision and accessibility for the most demanding thermal applications.

Summary Table:

| Feature | Benefit | Key Applications |

|---|---|---|

| Three-Zone Design | Ensures temperature uniformity and stability | CVD, annealing, material testing |

| Split-Tube Design | Allows easy loading of complex samples | Sintering, pyrolysis, crystal growth |

| Independent Control | Enables precise gradients and repeatability | Physical vapor transport, calibration |

Ready to elevate your lab's thermal processing with precision and ease? KINTEK specializes in advanced high-temperature furnace solutions, including Three-Zone Split Tube Furnaces, designed for demanding applications like CVD, annealing, and sintering. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your process efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity