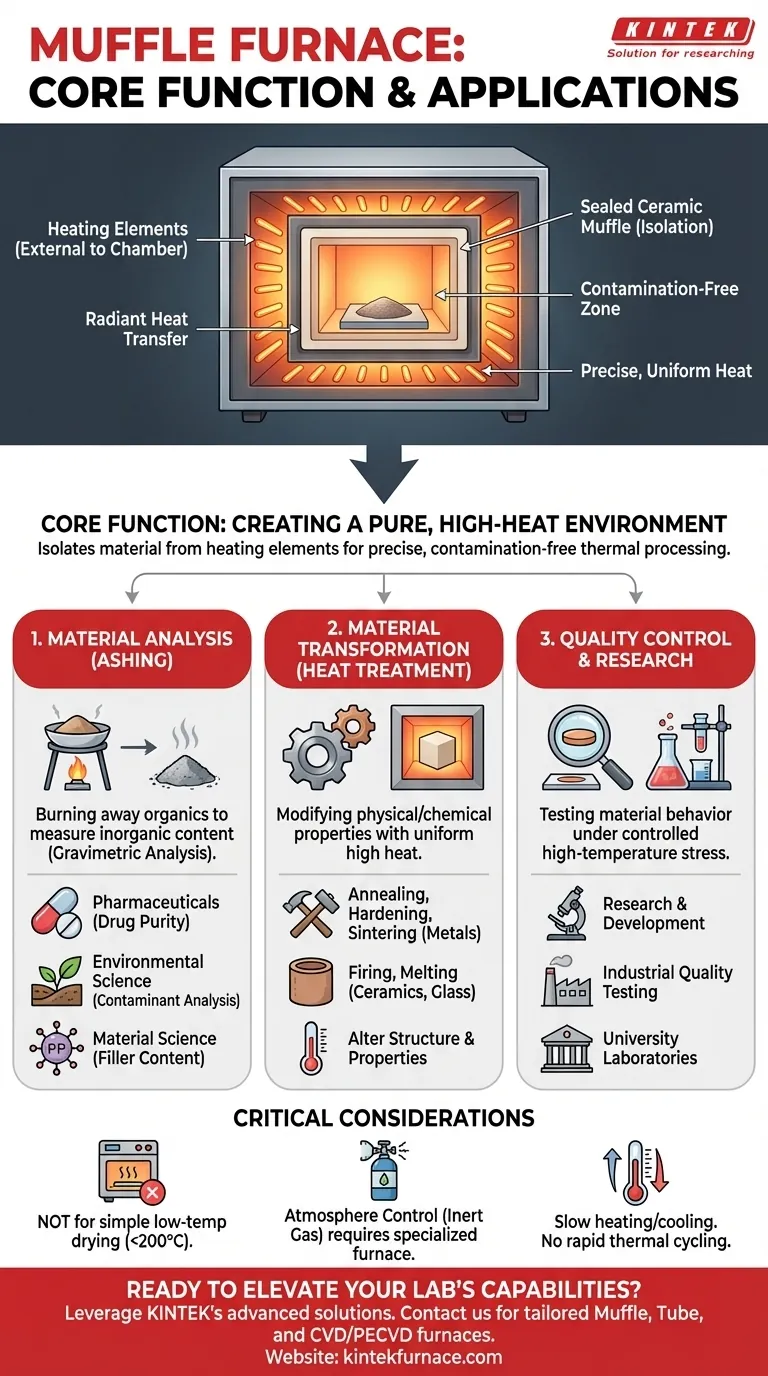

In essence, a muffle furnace is a high-temperature chamber oven used for transforming or analyzing materials. Its primary applications fall into three main categories: performing material decomposition for analysis (ashing), altering the physical properties of metals and ceramics (heat treatment), and conducting quality control tests in research, industrial, and university laboratories.

A muffle furnace is not simply an oven that gets very hot. Its defining feature is a sealed inner chamber—the "muffle"—that isolates the material being heated from the heating elements, ensuring a pure, contamination-free, and precisely controlled thermal environment.

The Core Function: Creating a Pure High-Heat Environment

Before listing applications, it is critical to understand why a muffle furnace is used. Its design solves a specific problem: the need for intense heat without direct exposure to flames or heating elements.

What "Muffle" Means

The term "muffle" refers to the furnace's sealed inner chamber, typically made of high-temperature ceramic. This chamber separates your sample from the heating coils.

Heat radiates through the walls of the muffle to heat the contents, rather than heating them directly.

Why This Isolation is Crucial

This separation provides two key benefits: temperature uniformity and a contamination-free environment. It prevents combustion byproducts or flakes from the heating elements from corrupting the sample, which is essential for precise chemical analysis and material processing.

Application 1: Material Analysis via Decomposition (Ashing)

One of the most common uses for a muffle furnace is ashing. This is the process of burning away all organic or volatile substances in a sample to determine what remains.

Determining Non-Combustible Content

By weighing a sample before and after ashing, analysts can precisely calculate its non-combustible and non-volatile content. This is a fundamental technique in gravimetric analysis.

Common Use Cases

This process is vital for quality control in many fields, including pharmaceuticals (testing drug purity), environmental science (analyzing soil or water contaminants), and material science (determining filler content in polymers).

Application 2: Transforming Materials with Heat Treatment

Heat treatment modifies the physical and chemical properties of a material. A muffle furnace provides the exact temperature control required for these sensitive processes.

Metals: Annealing, Hardening, and Sintering

In metallurgy, furnaces are used for processes like annealing (to soften metal and improve ductility), hardening (to increase strength), and sintering (fusing metal powders together below their melting point).

Ceramics and Glass: Firing and Melting

The furnace provides the consistent, high temperatures needed to fire ceramics, melt glass, or determine the ash melting point of a material. This is essential for creating materials with specific structural properties.

Common Pitfalls and Considerations

While powerful, a muffle furnace is a specialized tool. Understanding its limitations is key to using it effectively.

Not a Simple Drying Oven

A muffle furnace is designed for high-temperature applications, typically starting above 200°C. It is inefficient and often unsuitable for simple low-temperature drying or curing, where a convection or vacuum oven is more appropriate.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. If your process requires an inert or reactive gas environment (like nitrogen or argon to prevent oxidation), you need a specialized furnace with gas ports and a sealed door, which adds complexity and cost.

Heating and Cooling Rates

The thick insulation required for high temperatures means muffle furnaces heat up and cool down slowly. They are not designed for rapid thermal cycling. Forcing a cool-down can crack the ceramic muffle.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, match your primary goal to its core function.

- If your primary focus is analytical testing: A muffle furnace is essential for ashing, where you must burn away organic matter completely to measure the inorganic remainder accurately.

- If your primary focus is material science or metallurgy: The furnace's precise, uniform heat is necessary for processes like annealing, tempering, or sintering that fundamentally change a material's microstructure.

- If your primary focus is high-temperature quality control: The furnace provides a stable, repeatable environment for testing how materials behave under extreme thermal stress.

Ultimately, a muffle furnace is the definitive tool whenever your process demands high, uniform heat within a contamination-free environment.

Summary Table:

| Application Category | Key Uses | Industries/Fields |

|---|---|---|

| Material Analysis (Ashing) | Burning organic matter to determine inorganic content | Pharmaceuticals, Environmental Science, Material Science |

| Heat Treatment | Annealing, hardening, sintering of metals and ceramics | Metallurgy, Ceramics, Glass Manufacturing |

| Quality Control | Testing material behavior under high heat | Research, Industrial, University Laboratories |

Ready to elevate your lab's capabilities with a tailored muffle furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need precise temperature control for ashing or uniform heating for material transformations, we can help. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production