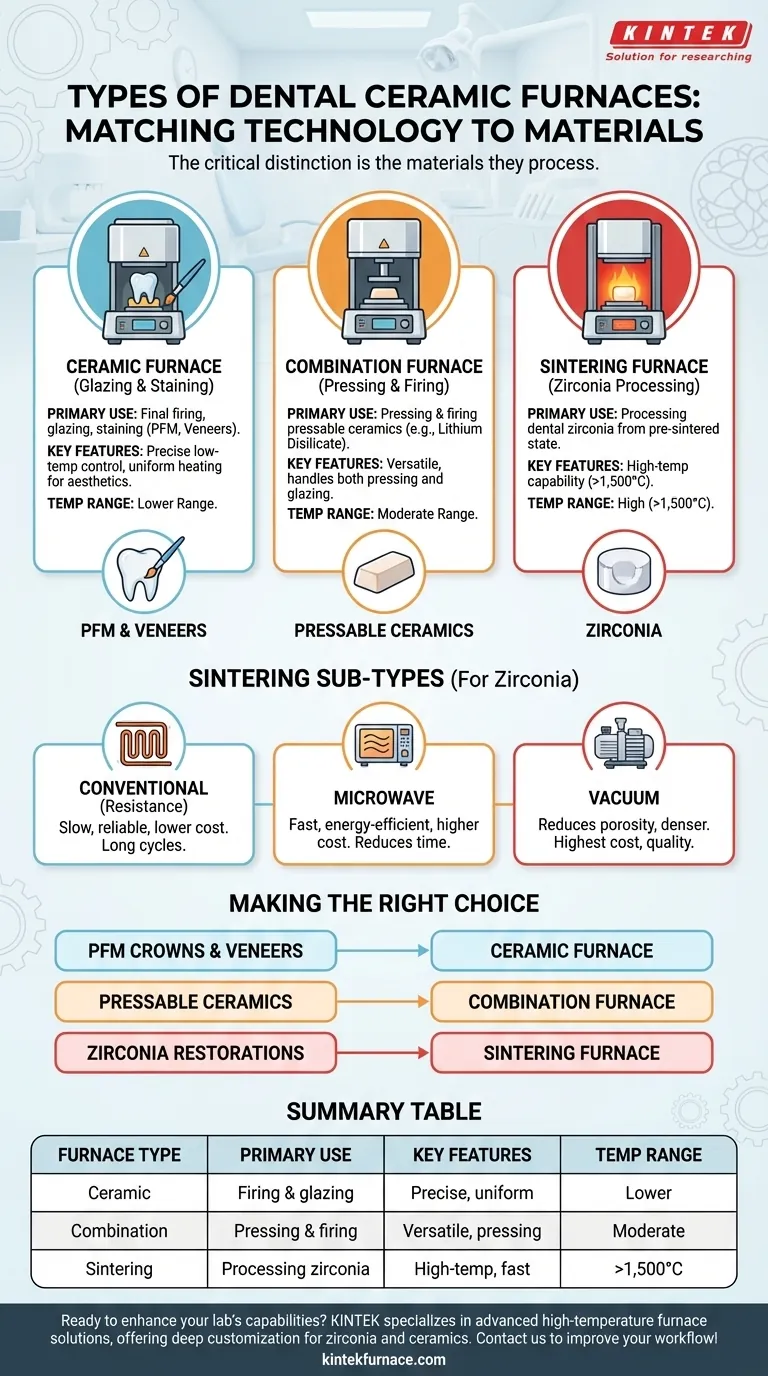

At a functional level, the dental industry primarily uses three types of furnaces, each designed for specific materials and processes. These are the standard Ceramic Furnace for glazing and staining, the versatile Combination Furnace for pressing and firing, and the high-temperature Sintering Furnace required for processing zirconia.

The critical distinction between dental furnaces is not their features, but the materials they are designed to process. Choosing the correct furnace means matching the equipment's heating capabilities—specifically its temperature range and control—to the precise requirements of either conventional porcelain, pressable ceramics, or zirconia.

Understanding the Core Furnace Types

While many furnaces are programmable, their fundamental purpose separates them into distinct categories. The type of restoration you produce dictates the furnace you require.

Ceramic Furnaces (For Firing and Glazing)

A standard ceramic furnace is the workhorse for finishing conventional ceramic restorations. Its primary role is the final firing, glazing, and staining of materials like porcelain-fused-to-metal (PFM) crowns and feldspathic veneers.

These furnaces operate at a lower temperature range compared to sintering units. They are engineered for extremely precise temperature control and uniform heating, which is essential for achieving lifelike aesthetics, translucency, and accurate color matching in the final product.

Combination Furnaces (For Pressing and Firing)

A combination furnace offers greater versatility. It performs all the functions of a standard ceramic furnace but adds the capability to press ceramic materials.

This makes it the ideal choice for labs and practices that work with pressable ceramics, such as lithium disilicate, in addition to conventional porcelain. These units can handle both the pressing of ingots and the final staining and glazing of the resulting restoration.

Sintering Furnaces (For Zirconia)

Sintering furnaces are in a class of their own, designed specifically for processing dental zirconia. Zirconia is milled in a soft, pre-sintered state and must be heated to extremely high temperatures (often over 1,500°C) to achieve its final, full-strength form.

A standard ceramic or combination furnace cannot reach these temperatures and is unsuitable for this process. Sintering furnaces are essential for any lab that wants to fabricate zirconia restorations in-house.

A Deeper Look at Sintering Technology

Because zirconia is such a dominant material, sintering furnace technology has evolved into its own sub-categories, primarily differing in speed, cost, and heating method.

Conventional Sintering Furnaces

These furnaces use traditional resistance heating elements (like MoSi2) to slowly bring the zirconia to its target temperature. While they are the most affordable and highly reliable, the firing cycles can be very long, often taking several hours.

Microwave Sintering Furnaces

As an alternative, microwave furnaces use microwave energy to heat the zirconia. This method is significantly faster and more energy-efficient, drastically reducing the production time for a zirconia crown. However, this speed and efficiency come with a higher initial equipment cost.

Vacuum Sintering Furnaces

For the highest possible quality, some advanced sintering processes use a vacuum. By removing air during the heating cycle, these furnaces reduce porosity within the zirconia, leading to a denser and potentially stronger final restoration. These units are typically the most expensive and may require more specialized operational knowledge.

Understanding the Trade-offs

Choosing a furnace involves balancing capability against the specific materials you use in your practice or lab.

Material Limitations

The most significant limitation is temperature. A ceramic furnace is fundamentally incapable of sintering zirconia. Conversely, a high-temperature sintering furnace is not designed for the delicate, nuanced heat control required for the aesthetic glazing of a porcelain veneer.

Cost vs. Capability

Ceramic furnaces are the most cost-effective solution for practices focusing exclusively on conventional porcelain work. Combination furnaces represent a moderate investment for added pressable capabilities, while sintering furnaces are a significant capital expense tied directly to providing zirconia services.

Workflow and Throughput

For labs producing a high volume of zirconia, the speed of a microwave sintering furnace can provide a substantial return on investment by increasing throughput. For lower volume work, the slower cycle of a conventional sintering furnace is often perfectly adequate.

Making the Right Choice for Your Lab

Your decision should be guided entirely by the services you offer and the materials you work with.

- If your primary focus is PFM crowns and feldspathic veneers: A standard ceramic furnace provides the precise, lower-temperature control you need for aesthetic finishing.

- If you work with pressable ceramics like lithium disilicate: A combination furnace that can both press ingots and fire porcelain is your most versatile and efficient choice.

- If you fabricate zirconia restorations in-house: A dedicated, high-temperature sintering furnace is absolutely essential.

Ultimately, matching your furnace technology to your chosen materials is the foundation for achieving predictable and high-quality restorative outcomes.

Summary Table:

| Furnace Type | Primary Use | Key Features | Temperature Range |

|---|---|---|---|

| Ceramic Furnace | Firing and glazing conventional ceramics | Precise temperature control, uniform heating | Lower range |

| Combination Furnace | Pressing and firing pressable ceramics | Versatile, handles pressing and glazing | Moderate range |

| Sintering Furnace | Processing zirconia | High-temperature capability, fast cycles | Over 1,500°C |

Ready to enhance your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs for materials like zirconia and ceramics. Contact us today to discuss how our furnaces can improve your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time