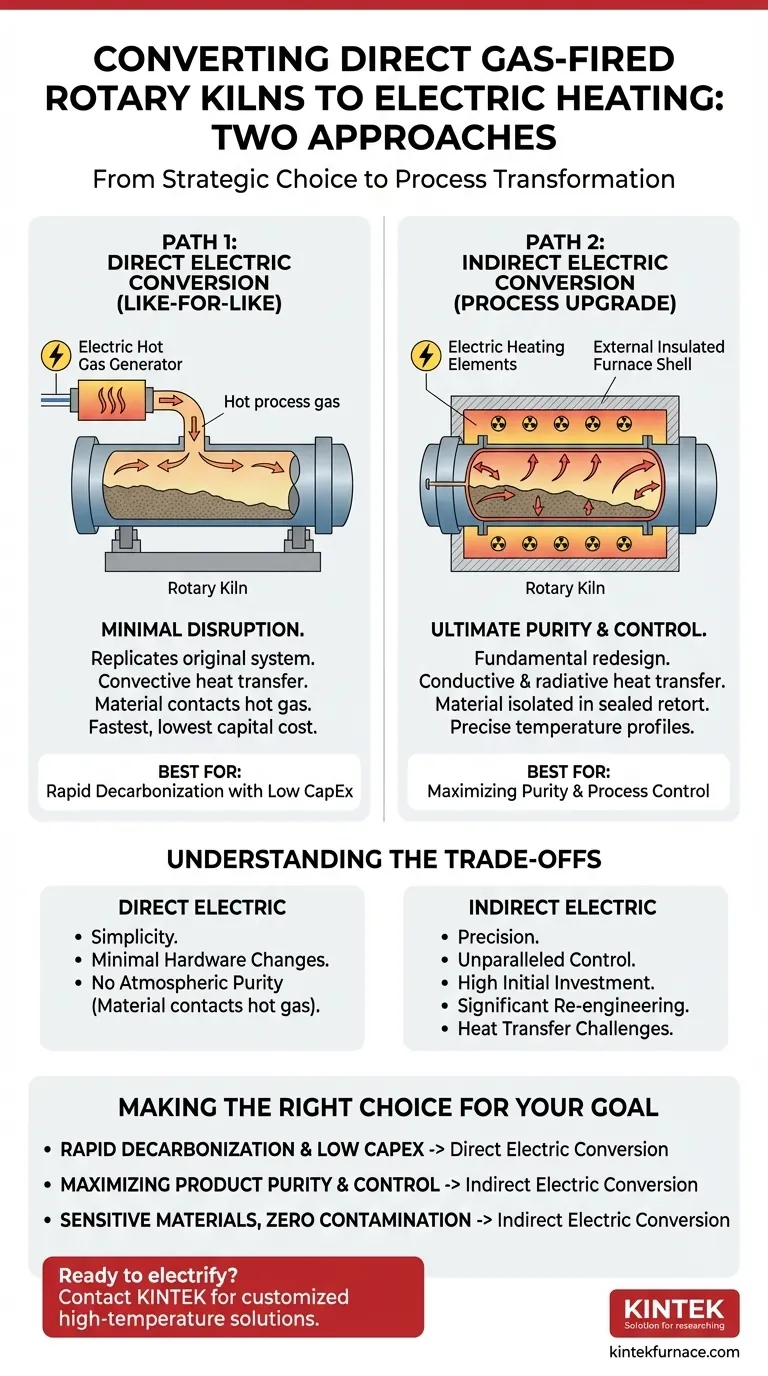

When converting a direct gas-fired rotary kiln to electric heating, you have two fundamentally different paths available. The first approach is to directly replace the internal gas burner with an electric hot gas generator, which mimics the function of the original system. The second, more transformative approach is to re-engineer the system for indirect electric heating, where external elements heat the kiln shell from the outside.

The decision to electrify a rotary kiln is not merely a component swap. It is a strategic choice between a direct replacement for minimal process disruption and a fundamental redesign toward an indirect system for superior process control and product purity.

Understanding the Core Difference: Direct vs. Indirect Heating

A rotary kiln's heating method is central to its design and function. Understanding the distinction between direct and indirect heating is the first step in evaluating a conversion.

Direct Heating: Heat Source Inside

In a traditional direct-fired kiln, a gas burner injects a flame and hot combustion gases directly into the rotating drum. The material being processed is in direct contact with these gases.

This method relies on convection as the primary mode of heat transfer, as the hot gases flow over and through the material bed.

Indirect Heating: Heat Source Outside

In an indirect kiln, the material is contained within a sealed drum, or retort. The heat source—in this case, electric elements—is located outside this retort.

Heat transfers through the retort wall to the material via conduction and radiation. This completely isolates the process material from the heating source and any byproducts.

Path 1: Direct Electric Conversion (The "Like-for-Like" Approach)

This path seeks to replicate the original direct-fired system using electricity. It is the most straightforward conversion method.

The Principle: The Electric Hot Gas Generator

Instead of a flame, an electric hot gas generator is installed. This device uses electric resistive elements to heat a process gas (such as air, nitrogen, or argon) to a very high temperature.

This superheated gas is then blown into the kiln, transferring heat to the material much like the original combustion gases did.

Key Advantage: Minimal Process Disruption

Because this method preserves the internal gas flow and convective heat transfer dynamics, it requires the least amount of change to the existing kiln hardware and process parameters. It is often the fastest and least capital-intensive option.

Path 2: Indirect Electric Conversion (The "Process Upgrade" Approach)

This path involves a more fundamental redesign of the kiln, changing from a direct to an indirect heating model.

The Principle: External Heating Elements

The internal burner is removed entirely. The kiln is retrofitted, or a new retort is installed, and surrounded by an insulated furnace shell containing electric heating elements.

These elements heat the outside of the rotating drum, and that heat conducts through the wall to the material inside. This requires a deep understanding of the process's thermal requirements.

Key Advantage: Ultimate Purity and Control

Because the material is isolated in a sealed retort, this method offers absolute control over the internal atmosphere. There is no contamination from combustion byproducts.

Furthermore, external elements can be arranged in multiple zones along the kiln's length, enabling exceptionally precise temperature profiles that are difficult to achieve with a single direct heat source.

Understanding the Trade-offs

Neither approach is universally superior. The correct choice depends entirely on your process goals and operational constraints.

Direct Electric: Simplicity vs. Atmosphere Control

The primary benefit of a direct electric conversion is its relative simplicity. However, you do not gain the core benefit of atmospheric purity, as the material is still in direct contact with the hot gas stream being blown into the kiln.

Indirect Electric: Precision vs. Complexity

Indirect heating offers unparalleled control over temperature and atmosphere, which can lead to higher-quality products. This comes at the cost of higher initial investment and significant re-engineering, as you are fundamentally changing the heat transfer mechanism.

Thermal Efficiency and Material Limits

Indirect heating can present challenges with heat transfer, as the kiln wall itself becomes a barrier. The choice of retort material is critical, as it must withstand high temperatures and efficiently conduct heat without degrading.

Making the Right Choice for Your Goal

To select the appropriate path, you must first define your primary objective for the conversion.

- If your primary focus is rapid decarbonization with minimal capital expense: A direct electric hot gas generator is the most straightforward path, replacing the burner with minimal process change.

- If your primary focus is maximizing product purity and process control: Converting to an indirect electric heating system is the superior long-term solution, as it decouples the heat source from the process atmosphere.

- If your primary focus is processing sensitive materials that cannot tolerate any contamination: Indirect electric heating is the only viable option, as it provides a completely isolated and controlled internal environment.

Ultimately, electrifying your kiln is an opportunity not just to change your energy source, but to fundamentally enhance your process.

Summary Table:

| Approach | Key Features | Best For |

|---|---|---|

| Direct Electric Conversion | Uses electric hot gas generator; minimal process disruption; convective heat transfer | Rapid decarbonization with low capital cost |

| Indirect Electric Conversion | Employs external heating elements; superior purity and control; conductive/radiative heat transfer | Maximizing product quality and process precision |

Ready to electrify your rotary kiln for enhanced efficiency and purity? KINTEK specializes in advanced high-temperature furnace solutions, including deep customization for your unique needs. Our product line—featuring Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—ensures precise control and superior performance. Contact us today to discuss how we can tailor a solution for your laboratory!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency