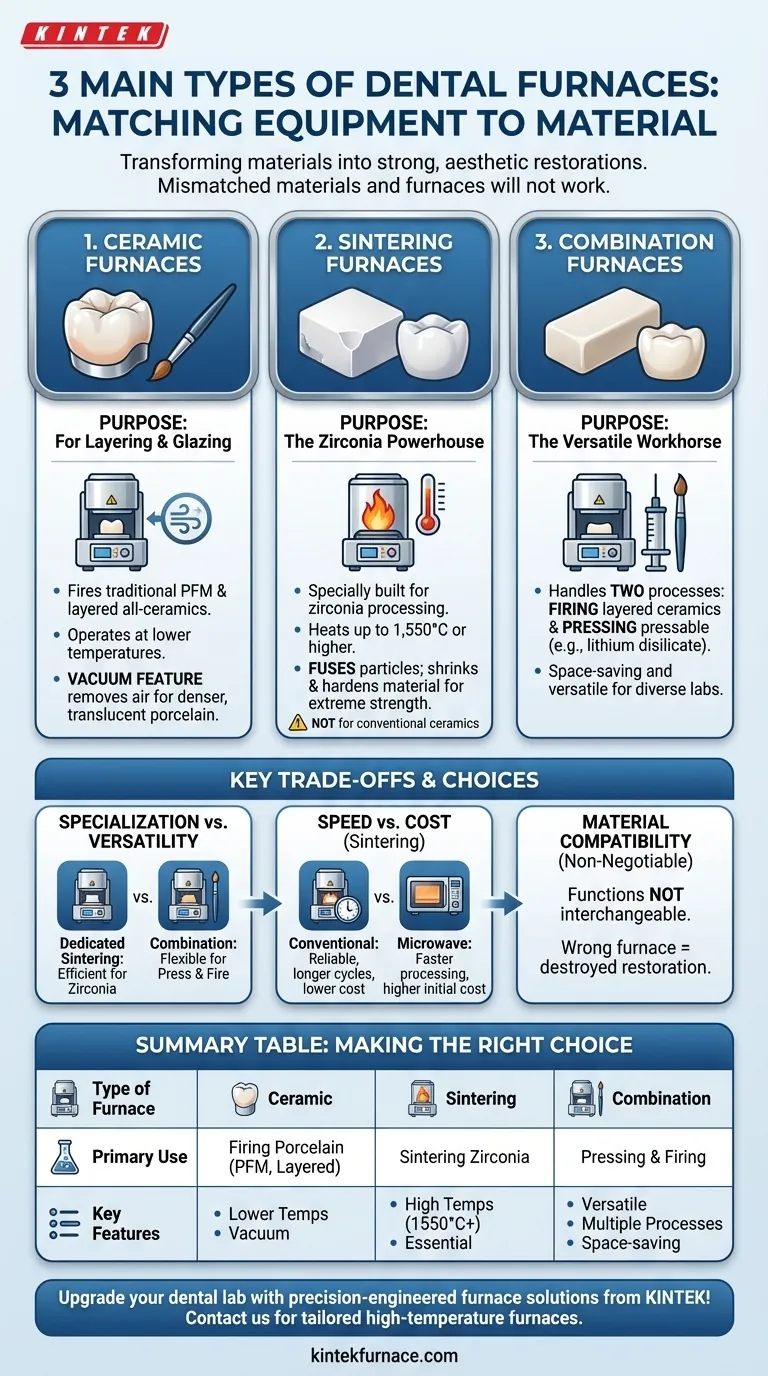

At its core, a dental furnace is a specialized, high-temperature oven used to process materials for restorations like crowns, bridges, and veneers. The three principal types are ceramic furnaces for firing porcelain, sintering furnaces for hardening zirconia, and combination furnaces that can both press and fire various ceramics. Each is designed for the unique thermal requirements of specific dental materials.

The critical takeaway is that the type of furnace you need is dictated entirely by the dental material you are processing. Mismatched materials and furnaces will not work, as each furnace is engineered to perform a specific thermal process—firing, pressing, or sintering—at precise temperatures and conditions.

The Purpose: Matching the Furnace to the Material

A dental furnace's job is to transform a raw or milled material into a strong, aesthetic, and perfectly fitting final restoration. The dramatic differences in material properties, especially between zirconia and conventional ceramics, necessitate different types of furnaces.

Ceramic Furnaces: For Layering and Glazing

A ceramic furnace, also called a firing furnace, is used for traditional porcelain-fused-to-metal (PFM) and layered all-ceramic restorations. Technicians apply layers of porcelain paste onto a core or framework, and each layer is fired in the furnace to harden it.

These furnaces operate at lower temperatures than sintering furnaces. Most modern ceramic furnaces are also vacuum furnaces, which remove air from the chamber during firing. This creates denser, stronger porcelain with fewer bubbles and higher translucency.

Sintering Furnaces: The Zirconia Powerhouse

Sintering furnaces are high-temperature units built specifically for processing zirconia. Zirconia restorations are milled from a pre-sintered, chalk-like block. This soft state is easy to mill, but it lacks the necessary strength for clinical use.

The sintering process heats the zirconia restoration to extremely high temperatures (up to 1,550°C or higher), causing the particles to fuse and the material to shrink into a dense, incredibly strong final state. You cannot sinter zirconia in a conventional ceramic furnace, as it cannot reach the required temperatures.

Combination Furnaces: The Versatile Workhorse

Combination furnaces are designed to handle two distinct processes: firing layered ceramics and pressing pressable ceramics like lithium disilicate (e.g., IPS e.max). The pressing function uses a plunger to press a heated, softened ceramic ingot into a mold.

After pressing, the same furnace can be used to fire layers of stain or glaze onto the restoration. This versatility makes them a popular and space-saving choice for labs that work with a wide range of materials but may not have the volume to justify separate pressing and firing units.

Understanding the Key Trade-offs

Choosing a furnace involves balancing specialization, cost, and the types of restorations your lab produces. Understanding the trade-offs is essential for making a sound investment.

Specialization vs. Versatility

A dedicated sintering furnace is a must-have for any lab focused on zirconia production. Its single purpose is to perform that high-temperature process efficiently.

A combination furnace is the model of versatility. It provides a lab with the flexibility to produce both beautiful pressable restorations and traditional layered crowns without buying two separate machines.

Speed vs. Cost in Sintering

Within sintering furnaces, there are further trade-offs. Conventional sintering furnaces are the standard, using traditional heating elements. They are reliable and less expensive upfront but have longer cycle times.

Newer microwave sintering furnaces use microwave energy to heat zirconia much faster, significantly reducing processing time. While more energy-efficient, they come with a higher initial purchase price.

Material Compatibility is Non-Negotiable

This is less a trade-off and more a fundamental rule. The functions are not interchangeable. A ceramic furnace lacks the temperature range to sinter zirconia, and a sintering furnace lacks the vacuum and precise low-temperature control for firing delicate porcelain layers. Attempting to use the wrong furnace will destroy the restoration and potentially damage the equipment.

Making the Right Choice for Your Lab

Your decision should be guided by the primary materials your lab will be working with.

- If your primary focus is zirconia restorations: You must have a dedicated sintering furnace.

- If your primary focus is pressable ceramics (e.g., lithium disilicate): A combination furnace with a pressing function is the most efficient choice.

- If your primary focus is traditional PFM and layered ceramics: A standard ceramic vacuum furnace is the correct tool for the job.

- If you are a versatile lab or just starting out: A combination furnace offers the greatest flexibility to adapt to different cases and materials.

Understanding the distinct role of each furnace empowers you to align your equipment capabilities with your production goals for predictable, high-quality results.

Summary Table:

| Type of Dental Furnace | Primary Use | Key Features |

|---|---|---|

| Ceramic Furnace | Firing porcelain for PFM and layered ceramics | Lower temperatures, vacuum capability for dense, bubble-free results |

| Sintering Furnace | Sintering zirconia for strength and density | High temperatures up to 1,550°C, essential for zirconia processing |

| Combination Furnace | Pressing and firing ceramics like lithium disilicate | Versatile, handles multiple processes, space-saving for diverse labs |

Upgrade your dental lab with precision-engineered furnace solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique experimental requirements. Whether you're processing zirconia, porcelain, or other ceramics, KINTEK ensures reliable performance and enhanced productivity. Contact us today to discuss how our furnaces can optimize your restoration workflows and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity