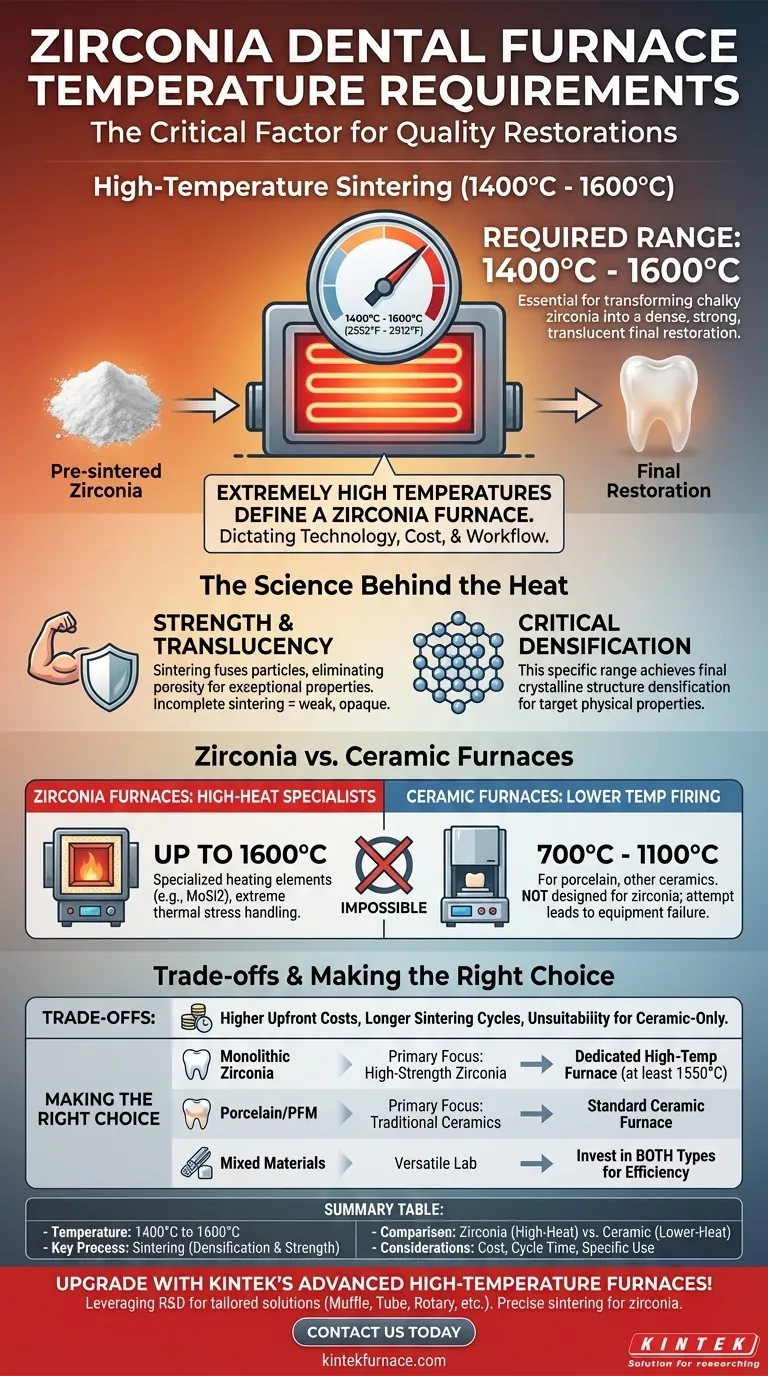

To properly sinter zirconia, a dental furnace must be capable of operating at extremely high temperatures. The required range is typically between 1400°C and 1600°C (2552°F to 2912°F). This specific temperature window is critical for transforming the milled zirconia from its chalky, pre-sintered state into a dense, strong, and translucent final restoration.

The need for extremely high temperatures is the single most important factor defining a zirconia furnace. This requirement dictates the furnace's technology, cost, and operational workflow, and fundamentally distinguishes it from furnaces used for traditional ceramics.

Why Zirconia Demands High-Temperature Sintering

Understanding the "why" behind the temperature reveals the science that ensures the quality of the final restoration. The entire process is centered on a material transformation called sintering.

The Goal of Sintering: Strength and Translucency

Sintering is the process of heating a powdered material to just below its melting point. This causes the individual particles to fuse together, eliminating the porous spaces between them.

For zirconia, this process is what imparts its exceptional strength and esthetic translucency. Incomplete sintering at lower temperatures results in a weaker, more opaque, and clinically unacceptable restoration.

The Critical Temperature Range

The range of 1400°C to 1600°C is not arbitrary. This is the temperature at which zirconia's crystalline structure undergoes its final densification.

Operating a furnace within this precise range, as specified by the zirconia manufacturer, ensures that the material reaches its target physical properties, including flexural strength and fracture resistance.

Zirconia vs. Ceramic Furnaces: A Key Distinction

A common point of confusion is whether one furnace can handle all dental materials. The temperature requirements create a clear technological divide.

Zirconia Furnaces: The High-Heat Specialists

These furnaces are engineered specifically to reach and maintain temperatures up to 1600°C or higher. They feature specialized heating elements (often molybdenum disilicide) and insulation designed to handle the extreme thermal stress of a zirconia cycle.

Ceramic Furnaces: Lower Temperature Firing

In contrast, furnaces used for firing porcelain and other dental ceramics operate at much lower temperatures, typically between 700°C and 1100°C.

These furnaces are not designed to reach the temperatures needed for zirconia sintering. Attempting to do so is impossible and would destroy the equipment.

Understanding the Trade-offs of High-Temperature Sintering

The necessity for high heat introduces several practical considerations that every dental lab or practice must weigh.

Higher Upfront Costs

The materials and technology required to safely and reliably produce temperatures over 1400°C make zirconia furnaces significantly more expensive than their lower-temperature ceramic counterparts.

Longer Sintering Cycles

A zirconia sintering cycle is not quick. It involves a slow ramp-up to the peak temperature, a "hold" or "soak" time at that temperature, and a carefully controlled cool-down period. This entire process can take several hours, impacting lab productivity and chairside turnaround times.

Unsuitability for Ceramic-Only Workflows

If a practice works exclusively with porcelain-fused-to-metal (PFM) or layered e.max restorations, investing in a high-temperature zirconia furnace is unnecessary. The equipment would be underutilized and not cost-effective for lower-temperature materials.

Making the Right Choice for Your Practice

Your decision on furnace technology must align directly with the materials you use most often.

- If your primary focus is high-strength monolithic zirconia restorations: A dedicated high-temperature furnace capable of reaching at least 1550°C is a non-negotiable investment for predictable results.

- If your primary focus is porcelain and other traditional ceramics: A standard ceramic furnace is the more efficient and cost-effective choice for your workflow.

- If you manage a versatile lab with a mix of materials: You will likely need to invest in both types of furnaces to optimize efficiency and avoid compromising the quality of either material.

Matching the furnace's capabilities to the material's requirements is the foundation of producing consistent, high-quality dental restorations.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 1400°C to 1600°C (2552°F to 2912°F) |

| Key Process | Sintering for densification and strength |

| Comparison | Zirconia furnaces: 1400°C-1600°C; Ceramic furnaces: 700°C-1100°C |

| Considerations | Higher cost, longer cycles, material-specific use |

Upgrade your dental lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise sintering for zirconia, delivering strong, translucent restorations efficiently. Contact us today to enhance your workflow and achieve superior results!

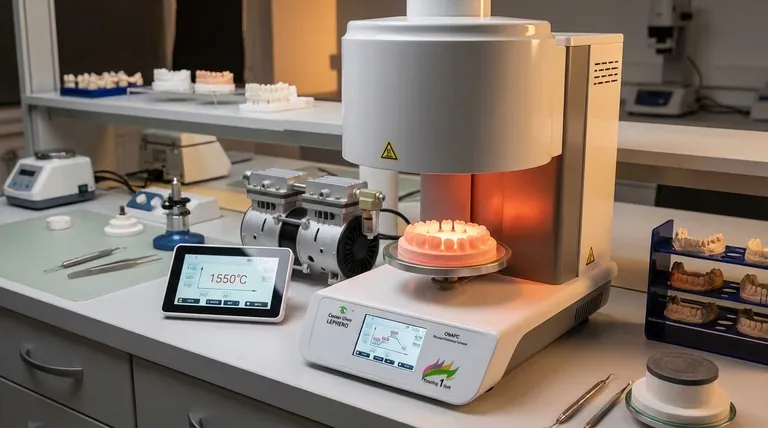

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab