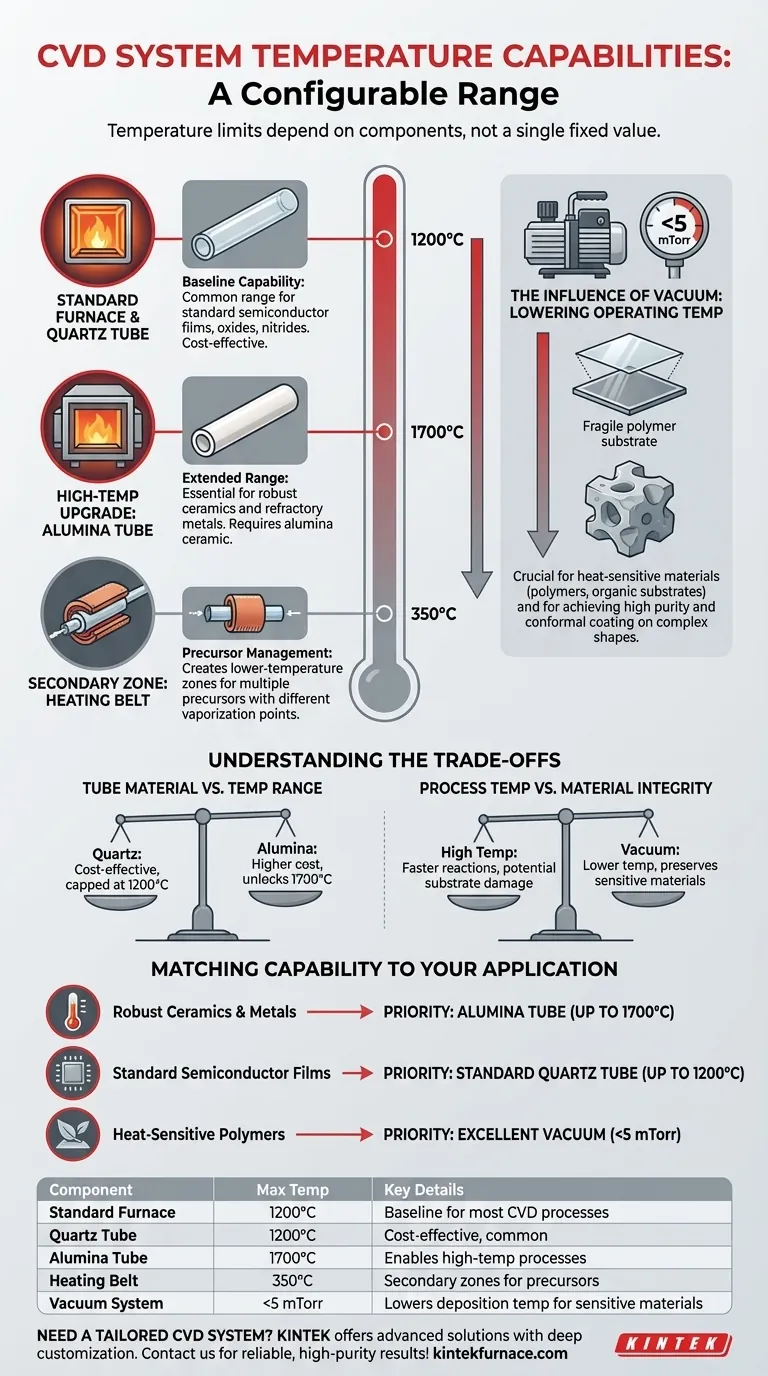

In short, the maximum temperature of a Chemical Vapor Deposition (CVD) system is not a single value but depends on its configuration. Standard furnaces with quartz process tubes can reach 1200°C, while swapping to an alumina tube can increase this capability to 1700°C. Additionally, secondary heating elements, like a heating belt, can create separate temperature zones up to 350°C for precursor management.

The true temperature capability of a CVD system is defined by its components—primarily the process tube material—and its ability to use vacuum to lower the required deposition temperature for sensitive materials.

Factors Defining Temperature Capability

To fully understand a CVD system's thermal performance, you must look beyond the furnace's maximum rating and consider the key components that dictate the practical operating range.

The Core Furnace Limit

The primary heating element, the furnace, is typically designed for a maximum temperature of 1200°C. This serves as the baseline capability for most standard CVD processes.

The Critical Role of the Process Tube

The material of the tube placed inside the furnace is the most significant factor.

- Quartz Tubes: These are common and can safely operate up to 1200°C, matching the standard furnace limit.

- Alumina Tubes: For processes requiring higher temperatures, an alumina ceramic tube is necessary. This allows the system's maximum operating temperature to be extended up to 1700°C.

Creating Secondary Heat Zones

For processes involving multiple precursors with different vaporization points, a supplemental heating belt can be added. This belt wraps around the gas lines outside the main furnace and can create a separate, lower-temperature zone of up to 350°C to pre-heat a second precursor.

Operating Temperature vs. Maximum Temperature

The maximum achievable temperature is only one part of the story. The true strength of a CVD system lies in its precise control across a wide range, including at much lower temperatures.

The Influence of Vacuum

CVD systems are equipped with vacuum pumps, reaching a base pressure of less than 5 mTorr. By reducing the system pressure, you can lower the temperature required for the chemical reactions to occur.

This principle is crucial when working with heat-sensitive materials whose structural or chemical properties would be compromised at high temperatures.

Why Purity and Control Matter

The precise control over temperature, combined with gas flow and pressure management, is what enables the key advantages of CVD. This control is directly responsible for producing films with exceptionally high purity (often >99.995%) and uniform thickness.

Because the reactants are in a gaseous state, they can flow around and coat complex, irregular geometries with a highly conformal layer, an outcome difficult to achieve with line-of-sight deposition methods.

Understanding the Trade-offs

Choosing the right configuration involves balancing competing requirements. Understanding these trade-offs is essential for a successful process.

Tube Material vs. Temperature Range

The choice is straightforward but critical: using a standard quartz tube is cost-effective and sufficient for many applications but caps your process at 1200°C. If your materials demand it, you must invest in a more expensive alumina tube to unlock the 1700°C range.

Process Temperature vs. Material Integrity

While high temperatures can increase reaction rates, they can also damage the underlying substrate. You must always weigh the need for a high deposition temperature against the thermal stability of the material you are coating. Leveraging the system's vacuum capability is the primary method for resolving this conflict.

Matching Temperature Capability to Your Application

Your specific goal will determine the necessary system configuration.

- If your primary focus is depositing robust ceramics or refractory metals: You must prioritize a system that supports an alumina process tube to safely reach temperatures up to 1700°C.

- If your primary focus is on standard semiconductor films, oxides, or nitrides: A standard system with a quartz tube capable of 1200°C is typically sufficient and the most common configuration.

- If your primary focus is coating heat-sensitive polymers or organic substrates: Your priority should be excellent vacuum control (<5 mTorr), which allows you to significantly lower deposition temperatures and preserve your material.

Ultimately, selecting the right CVD system is about matching its specific thermal and vacuum capabilities to the precise demands of your materials and desired outcome.

Summary Table:

| Component | Maximum Temperature | Key Details |

|---|---|---|

| Standard Furnace | 1200°C | Baseline for most CVD processes |

| Quartz Tube | 1200°C | Cost-effective, common for standard applications |

| Alumina Tube | 1700°C | Enables high-temp processes for ceramics and metals |

| Heating Belt | 350°C | Creates secondary zones for precursor management |

| Vacuum System | <5 mTorr | Lowers deposition temperature for sensitive materials |

Need a CVD system tailored to your lab's unique temperature requirements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our product line, featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, is enhanced by strong deep customization capabilities to precisely meet your experimental needs—whether you're working with heat-sensitive polymers or high-temp ceramics. Contact us today to discuss how we can optimize your deposition processes with reliable, high-purity results!

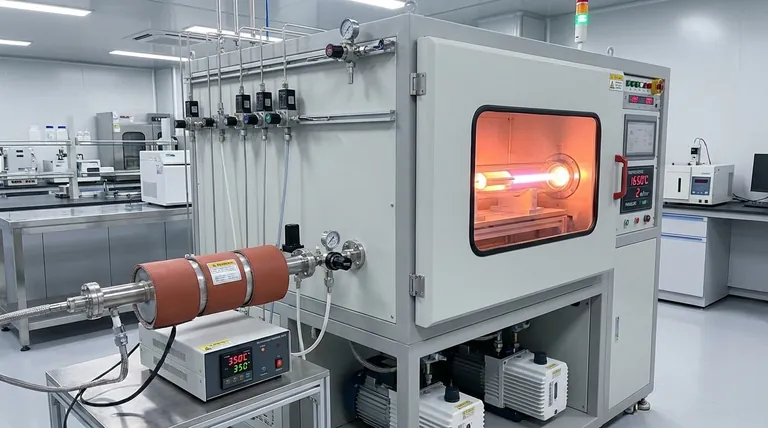

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition