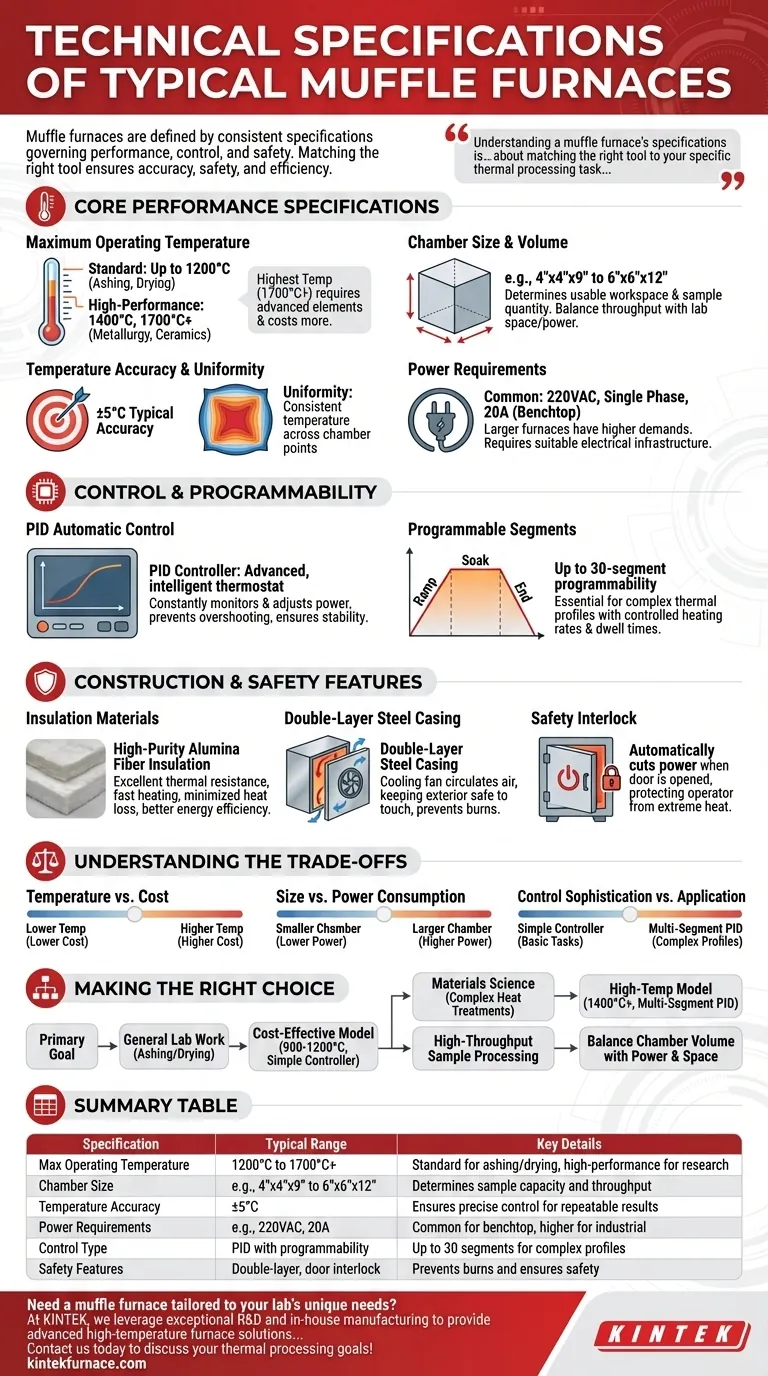

At their core, muffle furnaces are defined by a consistent set of technical specifications governing their performance, control, and safety. Key specifications typically include a maximum operating temperature between 1200°C and 1700°C, a programmable PID controller for precise temperature management, high-purity alumina fiber insulation for efficiency, and critical safety features like a double-layer cooled steel casing and an automatic power-off door interlock.

Understanding a muffle furnace's specifications is not just about knowing its limits; it's about matching the right tool to your specific thermal processing task, ensuring accuracy, safety, and efficiency.

Core Performance Specifications

The fundamental capability of any muffle furnace is defined by its ability to generate and maintain heat accurately within its chamber. These specifications are the primary determinants of what you can achieve.

Maximum Operating Temperature

The single most important specification is the maximum operating temperature. Standard laboratory furnaces typically operate up to 1200°C, which is sufficient for processes like ashing, drying, and basic heat treatments.

High-performance models for metallurgy, ceramics, or advanced materials research can reach temperatures of 1400°C, 1700°C, or higher. This capability dictates the types of materials and processes the furnace can handle.

Chamber Size and Volume

Chamber dimensions, often cited in inches (e.g., 4"x4"x9" or 6"x6"x12"), determine the usable workspace. This directly impacts the size and quantity of samples you can process at one time.

Choosing the right size is a balance between your throughput needs and the available lab space and power.

Temperature Accuracy and Uniformity

Accuracy refers to how close the chamber temperature is to the setpoint on the controller, with a typical value being ±5°C. Uniformity describes how consistent the temperature is across different points within the chamber.

For processes requiring high repeatability and precision, excellent accuracy and uniformity are non-negotiable.

Power Requirements

This specification dictates the electrical infrastructure needed to operate the furnace. A common requirement for benchtop models is 220VAC, single phase, 20A. Larger industrial furnaces will have significantly higher power demands.

Control and Programmability

Modern muffle furnaces are not simple ovens; they are sophisticated instruments whose value lies in precise, automated control over the heating process.

PID Automatic Control

Nearly all modern furnaces use a Proportional-Integral-Derivative (PID) controller. Think of this as an advanced, intelligent thermostat that constantly monitors the chamber temperature and makes tiny adjustments to the power.

This system actively prevents temperature overshooting and maintains the setpoint with high stability, which is crucial for sensitive processes.

Programmable Segments

A furnace with 30-segment programmability allows you to create complex thermal profiles. Each segment can be a ramp (heating/cooling at a specific rate), a soak (holding at a temperature for a set time), or an end step.

This is essential for processes that require controlled heating rates, specific dwell times, and gradual cooling to avoid thermal shock to the material.

Construction and Safety Features

The physical design of a muffle furnace is engineered for energy efficiency, durability, and, most importantly, user safety.

Insulation Materials

The use of high-purity fibrous alumina insulation is standard in quality furnaces. This material offers excellent thermal resistance, allowing the furnace to reach high temperatures quickly while minimizing heat loss. This directly translates to better energy efficiency.

Double-Layer Steel Casing

Furnaces feature a double-layer steel structure with a cooling fan circulating air between the inner and outer walls. This design keeps the exterior surface temperature low enough to be safe to the touch, preventing accidental burns in a busy lab environment.

Safety Interlock

A critical and non-negotiable feature is the door safety interlock. This mechanism automatically cuts power to the heating elements the moment the furnace door is opened, protecting the operator from direct exposure to extreme heat and ensuring a safer working environment.

Understanding the Trade-offs

Selecting a muffle furnace involves balancing capabilities with practical constraints. There is no single "best" model, only the best fit for a specific need.

Temperature vs. Cost

Higher maximum operating temperatures require more advanced heating elements, insulation, and power systems. As a result, a 1700°C furnace is significantly more expensive than a 1200°C model.

Size vs. Power Consumption

A larger internal chamber naturally requires more energy to heat and maintain its temperature. This not only increases operational costs but may also necessitate a dedicated, high-amperage electrical circuit.

Control Sophistication vs. Application

While multi-segment programmability is vital for materials science, it is overkill for simple ashing procedures. A basic, single-setpoint controller may be more cost-effective and easier to operate for straightforward, repetitive tasks.

Making the Right Choice for Your Application

Use your primary goal to guide your selection of the most important specifications.

- If your primary focus is general lab work like ashing or drying: A standard furnace with a maximum temperature of 900-1200°C and a simple controller is cost-effective and sufficient.

- If your primary focus is materials science or complex heat treatments: Prioritize a high-temperature (1400°C+) model with advanced, multi-segment PID programmability.

- If your primary focus is high-throughput sample processing: The internal chamber volume will be your most critical specification, balanced against power and space constraints.

By aligning the furnace's specifications with your intended application, you ensure you acquire a tool that is both capable and efficient for your needs.

Summary Table:

| Specification | Typical Range | Key Details |

|---|---|---|

| Max Operating Temperature | 1200°C to 1700°C+ | Standard for ashing/drying, high-performance for materials research |

| Chamber Size | e.g., 4"x4"x9" to 6"x6"x12" | Determines sample capacity and throughput |

| Temperature Accuracy | ±5°C | Ensures precise control for repeatable results |

| Power Requirements | e.g., 220VAC, 20A | Common for benchtop models, higher for industrial |

| Control Type | PID with programmability | Up to 30 segments for complex thermal profiles |

| Safety Features | Double-layer casing, door interlock | Prevents burns and ensures operator safety |

Need a muffle furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your experimental requirements, enhancing accuracy, safety, and efficiency. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation