The primary productivity benefit of induction melting furnaces is their ability to dramatically increase production output. This is achieved through a combination of exceptionally fast heating rates, superior energy efficiency, and precise process control, which together eliminate the delays and inefficiencies inherent in traditional furnace technologies.

The decision to adopt induction melting is not merely about melting metal faster. It is about fundamentally re-architecting your workflow from a slow, batch-based operation into a continuous, highly-controlled, and integrated manufacturing process.

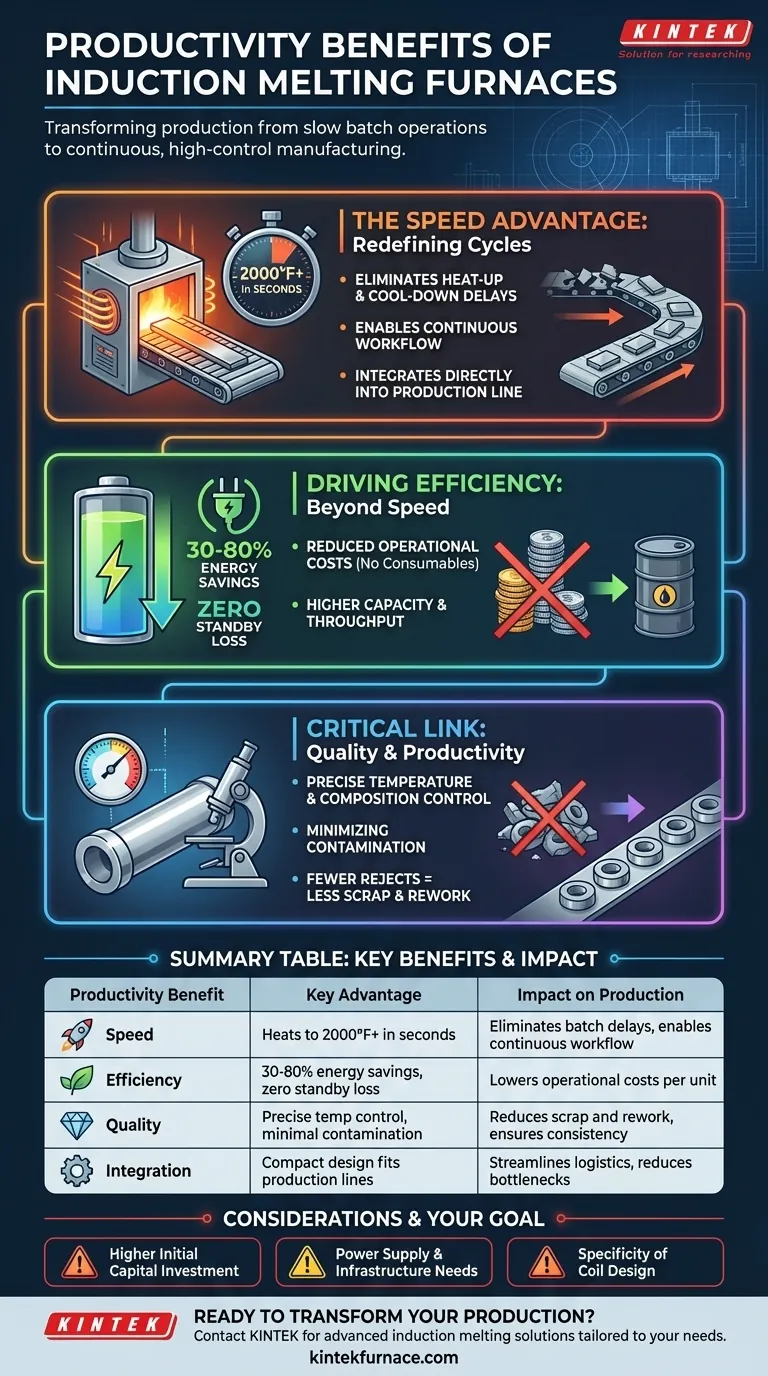

The Speed Advantage: Redefining Production Cycles

The most immediate productivity gain from induction technology comes from its raw speed, which ripples through the entire production line.

Eliminating Heat-Up and Cool-Down Delays

Induction furnaces can bring metal to temperatures over 2,000°F in under a second. Unlike conventional furnaces that require long pre-heating and cooling periods, an induction system is ready almost instantly and cools just as quickly.

This eliminates wait times between cycles, allowing operators to move from one task to the next without the typical delays associated with batch processing.

Enabling Continuous Workflow

The rapid heating and cooling cycle makes a continuous workflow possible. Instead of processing large, infrequent batches, production can be organized into a steady, uninterrupted flow.

This model is more predictable, easier to manage, and significantly boosts the number of units that can be processed in a given shift.

Integrating Directly into the Production Line

The compact and self-contained nature of induction furnaces allows them to be placed directly on the work floor as part of a larger production cell.

This eliminates the time and labor spent moving materials to and from a dedicated furnace room, streamlining logistics and reducing potential bottlenecks.

Driving Efficiency Beyond Speed

While speed is a major factor, the underlying efficiency of induction technology provides significant and compounding productivity benefits.

Unmatched Energy Efficiency

Induction furnaces offer 30–80% energy savings compared to traditional methods. Heat is generated directly within the metal itself, so no energy is wasted heating the furnace chamber or the surrounding air.

Furthermore, there is zero standby heat loss, as the furnace consumes almost no power when it is not actively melting. This directly translates to lower operational costs per unit produced.

Reduced Operational Costs

Productivity is also a function of cost. Induction systems eliminate the need for consumables like combustible fuels or carbon electrodes.

This not only lowers direct operational expenses but also removes the risks and logistical overhead associated with handling fuel. Minimal maintenance requirements further contribute to lower long-term costs and greater uptime.

Higher Capacity and Throughput

Modern IGBT-powered induction furnaces are engineered for higher melting capacity. They can handle larger volumes of material efficiently, allowing for an overall increase in manufacturing throughput.

The Critical Link Between Quality and Productivity

Higher quality output means less waste, fewer rejected parts, and less time spent on rework—all of which are critical components of overall productivity.

Precision Temperature and Composition Control

Induction technology provides extremely precise and repeatable control over temperature. The electromagnetic field also stirs the molten metal, ensuring a homogenous mixture and consistent alloy composition.

This level of control is essential for high-specification industries like aerospace and medical manufacturing, where material integrity is non-negotiable.

Minimizing Contamination for Fewer Rejects

Because heat is generated internally without any flame or combustion, the risk of contaminating the metal with impurities is virtually eliminated.

The uniform heating ensures all parts of the metal reach temperature simultaneously, improving consistency and reducing the likelihood of defects that lead to costly scrap.

Understanding the Trade-offs

While powerful, induction technology is not a universal solution. A clear-eyed assessment of its limitations is crucial for making an informed decision.

Higher Initial Capital Investment

Induction furnace systems typically require a higher upfront capital expenditure compared to some traditional fuel-fired furnaces. This investment must be weighed against the long-term operational savings and productivity gains.

Power Supply and Infrastructure Requirements

These systems are electrically demanding. A facility may require significant upgrades to its electrical infrastructure to support the high power draw of an industrial-scale induction furnace, adding to the initial project cost and complexity.

Specificity of Coil Design

The induction coil, which generates the magnetic field, is often optimized for a specific part size and shape. For operations with a very high mix of different products, this may require multiple coils and changeover time, slightly reducing the flexibility of the system.

Making the Right Choice for Your Goal

To determine if induction melting is the right fit, align the technology's core strengths with your primary production objective.

- If your primary focus is maximizing throughput: The rapid heating/cooling cycles are your greatest asset, enabling a true continuous-flow manufacturing model that eliminates batch delays.

- If your primary focus is reducing operational costs: The significant energy savings and elimination of consumables like fuel and electrodes offer the most direct path to a lower cost-per-part.

- If your primary focus is improving product quality and consistency: The precise temperature control and inherent stirring action will drastically reduce defects and ensure compliance with strict specifications.

Ultimately, adopting induction melting technology transforms the production process from a series of inefficient stops and starts into a streamlined, efficient, and highly controllable system.

Summary Table:

| Productivity Benefit | Key Advantage | Impact on Production |

|---|---|---|

| Speed | Heats metal to 2000°F+ in seconds | Eliminates batch delays, enables continuous workflow |

| Efficiency | 30-80% energy savings, zero standby loss | Lowers operational costs per unit |

| Quality | Precise temperature control, minimal contamination | Reduces scrap and rework, ensures consistency |

| Integration | Compact design fits directly into production lines | Streamlines logistics, reduces bottlenecks |

Ready to transform your metal production with the productivity power of induction melting?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Whether you're focused on maximizing throughput, reducing operational costs, or improving product quality, our induction melting systems are engineered to deliver unmatched performance.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your experimental and production requirements.

Contact us today to discuss how a KINTEK induction furnace can revolutionize your workflow and drive your productivity to new heights!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications