At its core, a porcelain furnace is a high-temperature oven designed for the precise processing of ceramic materials. Its primary applications revolve around dental technology, where it is used to fire, sinter, press, and glaze dental ceramics to create durable and aesthetic restorations like crowns and bridges.

A porcelain furnace is not merely a heat source; it is a precision instrument. Its value lies in its ability to execute highly controlled, programmable heating and cooling cycles—often under vacuum—to transform ceramic powders into strong, non-porous, and lifelike dental prosthetics.

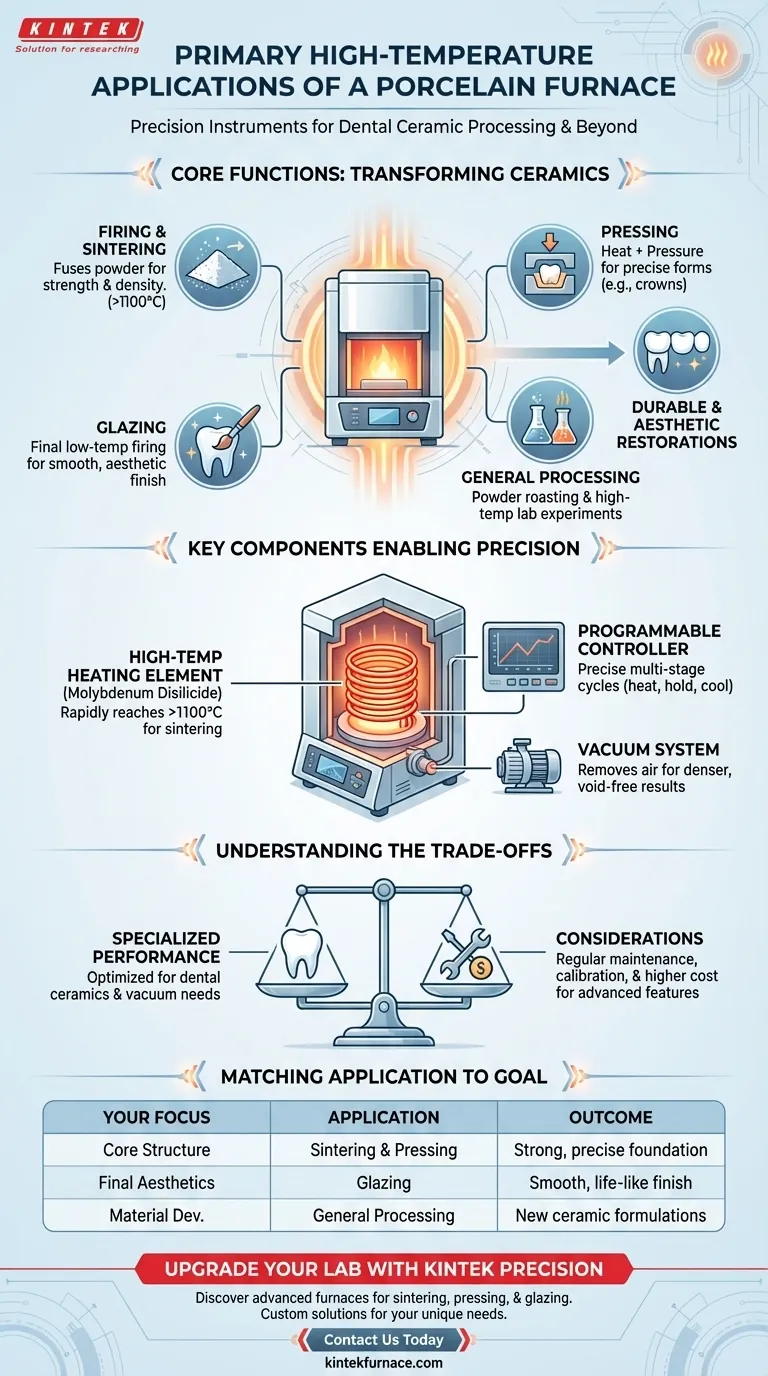

The Core Functions: Transforming Ceramic Materials

A porcelain furnace's applications are steps in a larger process of dental restoration fabrication. Each function manipulates the ceramic material in a specific way to achieve a desired outcome, from foundational strength to final aesthetics.

Firing and Sintering for Strength

This is the most fundamental application. Sintering involves heating ceramic powder to a temperature just below its melting point.

This process causes the individual particles to fuse, eliminating pores and creating a dense, hardened, and significantly stronger final structure. This is the step that provides the restoration with its essential durability.

Pressing for Precision Forms

Pressing combines heat with pressure to shape ceramic materials. A pre-heated ceramic ingot is pressed into a mold, allowing for the creation of incredibly precise and well-fitting restorations.

This method is commonly used to fabricate full-contour crowns, inlays, onlays, and veneers with high accuracy.

Glazing for a Final Finish

Glazing is a final firing step, typically at a lower temperature. A thin layer of glass-like material is applied to the sintered restoration and fired.

This creates a smooth, lustrous, and non-porous surface that mimics the appearance of natural tooth enamel while also increasing its resistance to staining and wear.

General Material Processing

While primarily dental-focused, these furnaces can also be used for related high-temperature tasks in a lab setting. This includes powder roasting to prepare specific ceramic blends or conducting high-temperature material science experiments.

Key Components Enabling Precision

The furnace's ability to perform these tasks is a direct result of its specialized components, which work together to ensure repeatable and accurate results.

The High-Temperature Heating Element

The heart of the furnace is its heating element, typically made from molybdenum disilicide. This material can rapidly and reliably reach the very high temperatures (often over 1100°C or 2012°F) required to sinter modern dental ceramics.

The Programmable Temperature Controller

Modern porcelain furnaces feature sophisticated digital controllers. This allows technicians to program multi-stage firing cycles with precise heating rates, hold times, and cooling profiles tailored to the specific ceramic being used.

The Vacuum System

Many advanced furnaces incorporate a vacuum pump. Firing ceramics under a vacuum removes air trapped between ceramic particles before they fuse. This results in a final restoration that is denser, stronger, and free of bubbles or voids.

Understanding the Trade-offs

While highly effective, these furnaces are specialized tools with inherent limitations and considerations.

Specialized vs. General-Purpose Use

A dental porcelain furnace is optimized for the specific firing cycles and vacuum requirements of dental ceramics. It is not a general-purpose laboratory furnace and may be inefficient or unsuitable for other high-temperature applications that do not require such precise control or vacuum capabilities.

Maintenance and Calibration Demands

To ensure consistent and accurate results, the furnace's temperature controller and thermocouple must be calibrated regularly. The heating element is a consumable part that will eventually require replacement, representing an ongoing operational cost.

Cost vs. Capability

The more features a furnace has—such as advanced programmability, a larger muffle (heating chamber), and integrated pressure systems—the higher its cost. A laboratory must balance the need for these capabilities against its budget and the types of restorations it produces most frequently.

Applying This to Your Goal

The specific application you use depends entirely on what stage of the restoration process you are in.

- If your primary focus is creating the core structure: Your goal will be met through sintering and pressing, which transform raw materials into a strong, precisely shaped foundation.

- If your primary focus is the final aesthetic and surface quality: You will use glazing to create a smooth, non-porous, and natural-looking finish on the restoration.

- If your primary focus is material development: You will leverage the furnace's capabilities for powder roasting and experimental heat treatments to create or test new ceramic formulations.

Ultimately, the porcelain furnace is the critical tool for transforming raw ceramic materials into functional and aesthetic dental art.

Summary Table:

| Application | Key Function | Outcome |

|---|---|---|

| Firing and Sintering | Heats ceramic powder to fuse particles | Creates strong, dense, non-porous dental restorations |

| Pressing | Applies heat and pressure to shape ceramics | Produces precise forms like crowns and veneers |

| Glazing | Fires a glass-like layer at lower temperatures | Achieves smooth, aesthetic, stain-resistant finish |

| Material Processing | Used for powder roasting and experiments | Supports ceramic development and lab tasks |

Upgrade your dental lab with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met for sintering, pressing, and glazing dental ceramics. Contact us today to enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab