In research, rotary tube furnaces are primarily used for high-temperature thermal processing of powders and granular materials where exceptional uniformity is required. Key applications include the synthesis of advanced materials like catalysts and ceramics, the sintering of metal powders, performing specific chemical reactions like calcination and reduction, and doping materials with precise concentrations of other elements.

The fundamental advantage of a rotary tube furnace is its ability to tumble the material during heating. This continuous mixing ensures every particle experiences the same temperature and atmospheric conditions, leading to highly consistent, repeatable, and homogenous results that are often impossible to achieve in a static furnace.

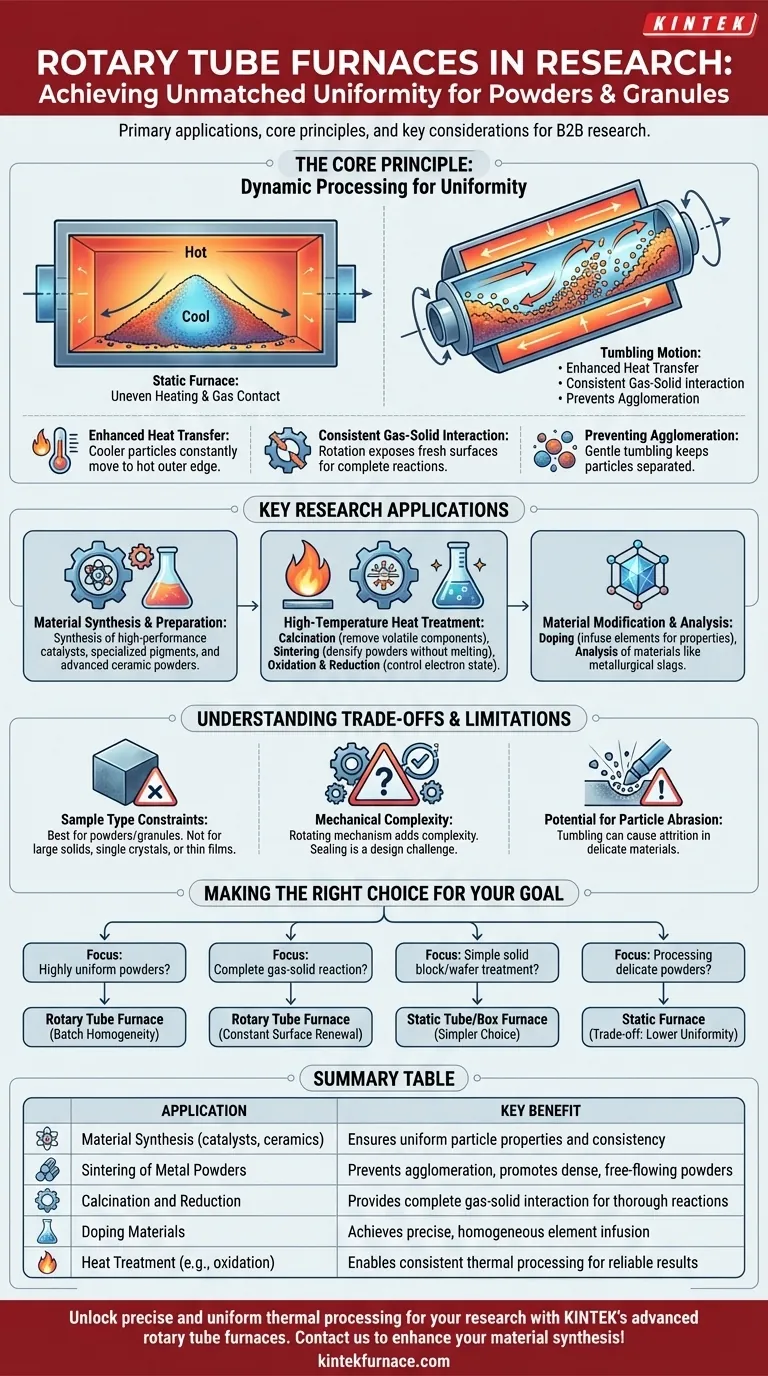

The Core Principle: Dynamic Processing for Unmatched Uniformity

The defining feature of a rotary tube furnace is its rotating process tube. This simple mechanical action fundamentally changes how heat and gases interact with a sample, making it an indispensable tool for specific research objectives.

How Rotation Enhances Heat Transfer

In a standard, static furnace, a powder sample heats unevenly. The outer layers can get much hotter than the core, leading to inconsistent material properties.

The tumbling motion of a rotary furnace constantly brings cooler particles from the inside of the sample to the outer edge, ensuring rapid and exceptionally uniform heating throughout the entire batch.

Ensuring Consistent Gas-Solid Interaction

Many advanced material processes involve reacting a solid powder with a specific gas, such as oxidation (with oxygen) or reduction (with hydrogen).

Rotation continuously exposes fresh particle surfaces to the process gas. This prevents the formation of a reacted outer "crust" that would otherwise block the gas from reaching the core of the sample, ensuring a complete and uniform chemical reaction.

Preventing Undesirable Agglomeration

When heating powders near their melting point (a process called sintering), particles tend to stick together and form larger, undesirable clumps.

The gentle tumbling action helps to keep the particles separated, promoting the creation of a dense but free-flowing powder rather than a single solid mass.

Key Research Applications Breakdown

The principle of dynamic, uniform processing enables a wide range of specialized research applications that are difficult or impossible with other furnace types.

Material Synthesis and Preparation

Rotary furnaces are workhorses for creating new materials from precursor powders. This includes the synthesis of high-performance catalysts, specialized pigments, and advanced ceramic powders, where the final properties are critically dependent on process uniformity.

High-Temperature Heat Treatment

These furnaces excel at specific heat treatments that transform materials.

- Calcination: A process of thermal decomposition to remove volatile components, such as converting oil shale or creating cement clinker.

- Sintering: Densifying metal or ceramic powders to increase strength and create new parts without fully melting the material.

- Oxidation & Reduction: Precisely controlling the electron state of a material, such as the gaseous reduction of metal ores to their base metals.

Material Modification and Analysis

The precise control offered is ideal for modifying existing materials. A key example is doping, where a ceramic powder is uniformly infused with a small amount of another element (like a rare earth metal) to alter its optical or electronic properties. It is also used for the analysis of materials like metallurgical slags.

Understanding the Trade-offs and Limitations

While powerful, a rotary tube furnace is a specialized tool and not always the right choice. Understanding its limitations is key to making an informed decision.

Sample Type Constraints

These furnaces are designed almost exclusively for powders, granules, or small pellets. They are not suitable for processing large solid objects, single crystals, or thin films, which would be damaged by the tumbling action.

Mechanical Complexity and Sealing

The rotation mechanism adds mechanical complexity compared to a static furnace. Achieving a perfect, gas-tight seal on a continuously rotating tube is a significant engineering challenge and a potential point of failure or atmospheric contamination if not designed properly.

Potential for Particle Abrasion

For very delicate or soft materials, the constant tumbling can cause abrasion (attrition), where particles grind against each other and break down. This can alter the particle size distribution and may be undesirable for certain applications.

Making the Right Choice for Your Research Goal

To determine if a rotary tube furnace is the correct instrument, you must evaluate your primary objective.

- If your primary focus is synthesizing highly uniform powders (e.g., catalysts, phosphors): The rotary tube furnace is the superior choice for achieving batch homogeneity.

- If your primary focus is ensuring a complete gas-solid reaction (e.g., ore reduction, oxidation): The constant surface renewal provided by tumbling makes this the ideal tool.

- If your primary focus is simple heat treatment of a solid block, wafer, or single crystal: A standard (static) tube furnace or box furnace is a simpler and more appropriate choice.

- If your primary focus is processing delicate powders that cannot tolerate mechanical stress: You may need to use a static furnace and accept the trade-off of potentially lower sample uniformity.

Ultimately, choosing a rotary tube furnace is a decision to prioritize sample homogeneity and reaction efficiency above all else.

Summary Table:

| Application | Key Benefit |

|---|---|

| Material Synthesis (e.g., catalysts, ceramics) | Ensures uniform particle properties and consistency |

| Sintering of Metal Powders | Prevents agglomeration and promotes dense, free-flowing powders |

| Calcination and Reduction | Provides complete gas-solid interaction for thorough reactions |

| Doping Materials | Achieves precise, homogeneous element infusion |

| Heat Treatment (e.g., oxidation) | Enables consistent thermal processing for reliable results |

Unlock precise and uniform thermal processing for your research with KINTEK's advanced rotary tube furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature solutions tailored for laboratories working with powders and granular materials. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to enhance your material synthesis and achieve superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation