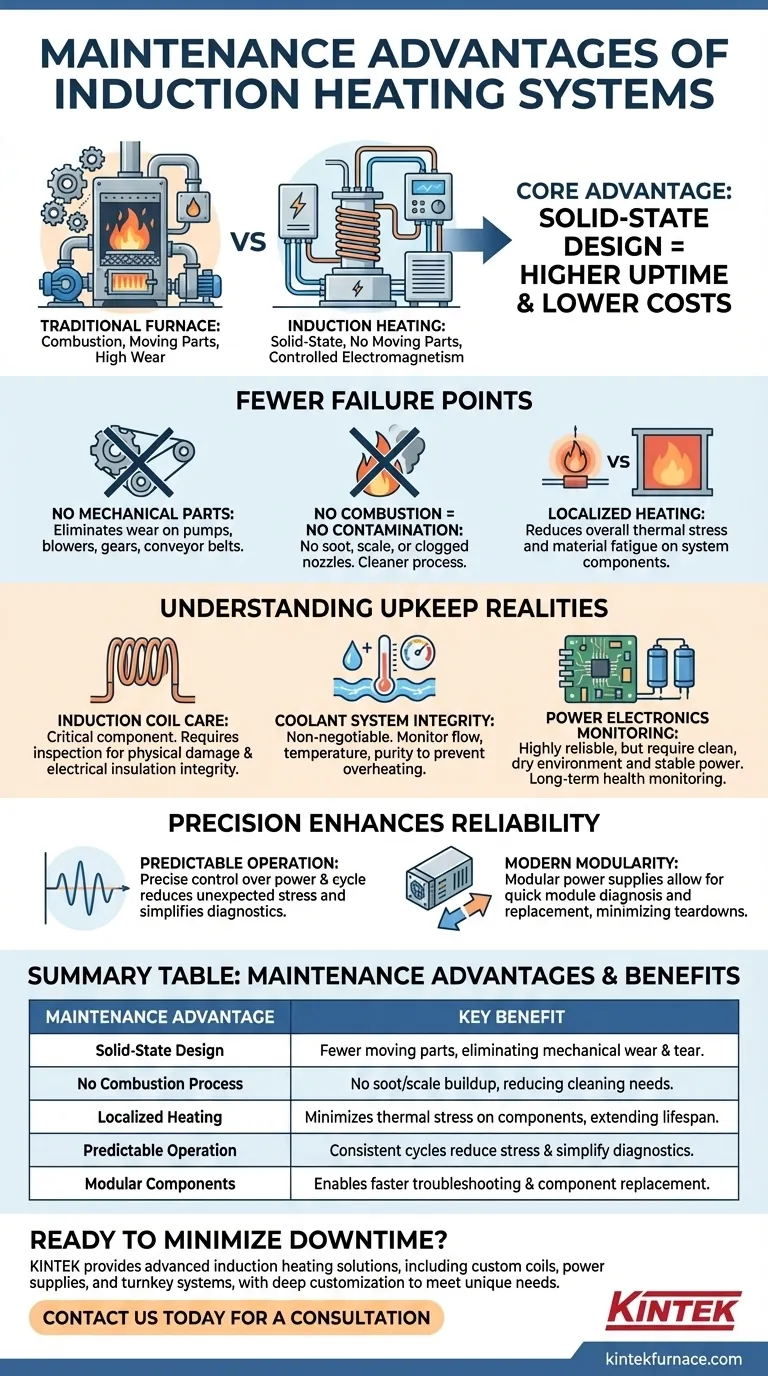

From a maintenance perspective, the primary advantage of induction heating is its solid-state design. Unlike traditional furnaces that rely on combustion and numerous moving parts, an induction system generates heat via an electromagnetic field. This fundamental difference means there are far fewer components to wear out, break down, or require frequent service, leading to significantly higher uptime and lower long-term operational costs.

The superior reliability of induction heating is a direct consequence of its core technology. By replacing mechanical complexity and combustion with controlled electromagnetism, it fundamentally shifts the maintenance burden from frequent, reactive repairs to predictable, long-term system health monitoring.

Why Induction Systems Have Fewer Failure Points

The low-maintenance nature of induction heating is not an accident; it is engineered into the system's basic principles. It eliminates the most common sources of breakdown found in conventional heating methods.

The Absence of Mechanical Parts

Traditional furnaces depend on a host of mechanical components like fuel pumps, blowers, gears, and conveyor belts. Each of these parts represents a potential point of failure through wear, misalignment, or fatigue.

Induction systems are almost entirely free of these components. The process is driven by electronics, eliminating the most frequent and disruptive sources of maintenance downtime.

No Combustion, No Contamination

Furnaces that burn fossil fuels inevitably produce byproducts like soot and scale. These residues must be cleaned regularly to prevent burner nozzles from clogging and to maintain a clean operating environment.

Induction heating is a completely clean process. Since there is no combustion, there is no residue to clean from the equipment, simplifying upkeep and ensuring consistent performance.

Localized Heating Reduces System Stress

An induction coil only heats the conductive material placed inside it. The surrounding equipment and the system itself are not subjected to the intense, widespread thermal cycling common in a large furnace.

This localization of heat dramatically reduces thermal stress and material fatigue on the system's own components, contributing to a longer operational lifespan for the entire installation.

Understanding the Realities of Upkeep

While mechanically simple, induction systems are sophisticated electronic devices. Their maintenance focus shifts from mechanical wear to electrical and cooling system integrity.

The Induction Coil is a Critical Component

The induction coil itself is the heart of the system. While it has no moving parts, it is made of copper tubing and is susceptible to damage from physical impact or electrical arcing if a workpiece is positioned incorrectly.

Coil maintenance is primarily about inspection and care. Ensuring its structural integrity and electrical insulation is key to efficient and safe operation.

Coolant System Integrity is Non-Negotiable

To handle immense electrical currents, the induction coil and power supply must be actively cooled, typically with water. The cooling system is the lifeblood of the induction heater.

Proper maintenance demands regular checks of coolant flow, temperature, and purity. A failure in the cooling system can quickly lead to overheating and catastrophic failure of the coil or expensive power electronics.

Monitoring Power Electronics

The system is powered by a sophisticated AC power supply and resonant capacitors. These are highly reliable, solid-state components with long lifespans, but they are not immune to failure.

Upkeep involves ensuring they operate in a clean, dry environment with stable input power. Maintenance is more about long-term health monitoring and planned replacement than reactive repair.

How Precision Control Enhances Reliability

The defining features of induction heating—its accuracy and controllability—also play a direct role in its reliability and ease of maintenance.

Predictable Operation Reduces Unexpected Stress

Induction allows for extremely precise control over power, frequency, and cycle time. This means the system operates within a narrow, predictable window, cycle after cycle.

This consistency minimizes random thermal and electrical shocks that can stress components, making failures far less frequent. When issues do arise, the repeatable nature of the process makes diagnostics simpler and faster.

Modern Modularity Simplifies Repairs

Many modern induction systems are designed with modular components, particularly the power supply.

If a fault occurs, a specific module can often be diagnosed and swapped out quickly, dramatically reducing troubleshooting and repair time compared to the extensive teardown that might be required for a monolithic furnace.

Making the Right Choice for Your Operation

Deciding on a heating technology requires weighing maintenance profiles against your specific production goals. Induction heating's advantages are clearest when uptime and quality are paramount.

- If your primary focus is maximum uptime and repeatability: Induction is superior, as its solid-state design eliminates the most common sources of mechanical failure found in traditional furnaces.

- If your primary focus is process quality: The precise, controllable heating of induction not only improves the end product but also reduces thermal stress on the equipment, directly contributing to its long-term reliability.

- If your primary focus is shifting maintenance skill sets: Adopting induction moves the burden from mechanical repairs (welding, gears, pumps) to electrical and cooling system monitoring, which requires a different but often more predictable expertise.

Ultimately, investing in induction heating is an investment in a cleaner, more precise, and highly reliable production process.

Summary Table:

| Maintenance Advantage | Key Benefit |

|---|---|

| Solid-State Design | Fewer moving parts, eliminating mechanical wear and tear. |

| No Combustion Process | No soot or scale buildup, reducing cleaning needs. |

| Localized Heating | Minimizes thermal stress on system components, extending lifespan. |

| Predictable Operation | Consistent cycles reduce unexpected stress and simplify diagnostics. |

| Modular Components | Enables faster troubleshooting and component replacement. |

Ready to Minimize Downtime and Maximize Your Production Efficiency?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse industrial facilities with advanced induction heating solutions. Our product line, including custom induction coils, power supplies, and complete turnkey systems, is complemented by our strong deep customization capability to precisely meet your unique thermal processing requirements.

Contact us today to discuss how our reliable, low-maintenance induction heating systems can enhance your operation's uptime and quality. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat