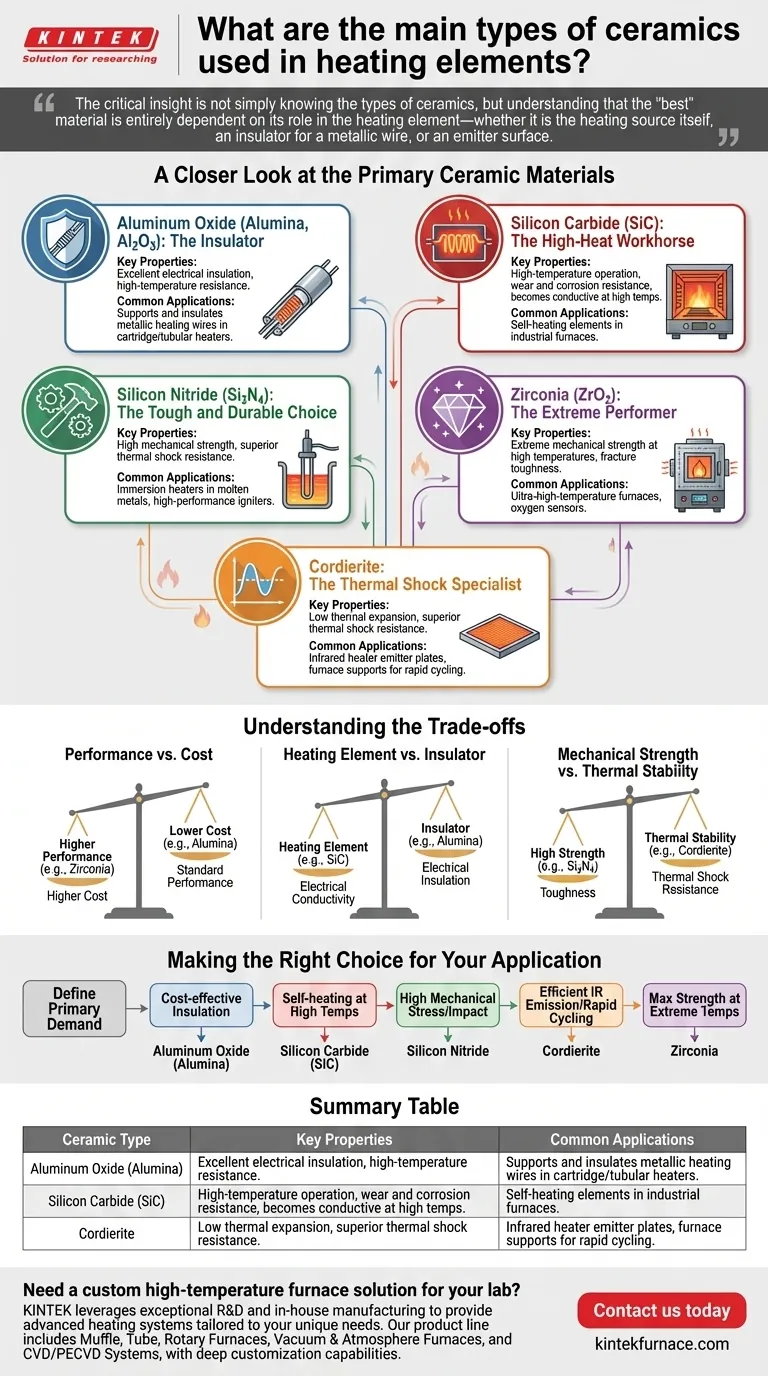

At their core, heating elements primarily use five types of advanced ceramics: Aluminum Oxide (Alumina), Silicon Carbide, Silicon Nitride, Zirconia, and Cordierite. Each material is selected for a unique combination of properties, including its ability to withstand extreme temperatures, provide electrical insulation, or resist mechanical and thermal shock.

The critical insight is not simply knowing the types of ceramics, but understanding that the "best" material is entirely dependent on its role in the heating element—whether it is the heating source itself, an insulator for a metallic wire, or an emitter surface.

A Closer Look at the Primary Ceramic Materials

Choosing the right ceramic involves matching the material's inherent properties to the specific demands of the heating application, such as operating temperature, environment, and physical stresses.

Aluminum Oxide (Alumina, Al2O3): The Insulator

Aluminum Oxide, commonly known as Alumina, is the most widely used ceramic in heating elements due to its exceptional electrical insulation and high-temperature resistance.

It is rarely the heating element itself. Instead, its primary role is to serve as a robust, non-conductive structure that supports and electrically isolates a metallic heating wire, like a nickel-chromium alloy. This is common in cartridge and tubular heaters.

Silicon Carbide (SiC): The High-Heat Workhorse

Unlike Alumina, Silicon Carbide can act as the heating element itself. It is a semiconductor that becomes more electrically conductive at high temperatures, allowing it to generate intense heat.

SiC elements are valued for their ability to operate in extremely hot environments, such as industrial furnaces, and for their resistance to wear and chemical corrosion.

Silicon Nitride (Si3N4): The Tough and Durable Choice

Silicon Nitride is prized for its outstanding mechanical strength and toughness, even at high temperatures. It offers superior resistance to thermal shock compared to many other ceramics.

This durability makes it ideal for applications involving rapid temperature changes or high physical stress, such as immersion heaters in molten metals or high-performance igniters.

Zirconia (ZrO2): The Extreme Performer

Zirconia stands out for its excellent mechanical strength and fracture toughness at the highest operating temperatures, even exceeding that of Silicon Nitride in some conditions.

It maintains its structural integrity in the most demanding environments, but its high cost reserves its use for specialized applications like ultra-high-temperature furnaces or oxygen sensors.

Cordierite: The Thermal Shock Specialist

Cordierite's defining characteristic is its extremely low coefficient of thermal expansion. This means it expands and contracts very little when heated and cooled.

This property makes it exceptionally resistant to cracking from thermal shock, rendering it the ideal material for infrared heater emitter plates and furnace supports that undergo rapid temperature cycling.

Understanding the Trade-offs

No single ceramic material is superior in all aspects. The selection process is a matter of balancing competing properties to meet the application's most critical requirements.

Performance vs. Cost

There is a direct correlation between a ceramic's performance capabilities and its cost. General-purpose Alumina is relatively inexpensive, while high-purity Zirconia for extreme environments is significantly more expensive. Prioritizing the most necessary property is key to cost-effective design.

Heating Element vs. Insulator

A fundamental trade-off exists between electrical conductivity and insulation. Materials like Silicon Carbide are chosen to be the heating element. In contrast, materials like Aluminum Oxide are chosen to contain a heating element, preventing electrical shorts and directing heat.

Mechanical Strength vs. Thermal Stability

A material like Silicon Nitride offers incredible toughness and is ideal for mechanically demanding roles. However, for applications where the primary challenge is rapid heating and cooling cycles, Cordierite's superior thermal shock resistance makes it the better choice, even if it has lower mechanical strength.

Making the Right Choice for Your Application

To select the appropriate material, first define the single most important demand of your heating system.

- If your primary focus is cost-effective electrical insulation for metallic elements: Aluminum Oxide (Alumina) is the industry standard for sheaths and supports.

- If you need a direct, self-heating element for very high temperatures: Silicon Carbide is the proven workhorse for industrial furnaces.

- If your application involves high mechanical stress or risk of impact: Silicon Nitride provides the necessary fracture toughness and durability.

- If your goal is efficient infrared emission with rapid heating and cooling: Cordierite's low thermal expansion makes it the ideal choice for emitter plates.

- If your project demands maximum strength at extreme temperatures and cost is secondary: Zirconia offers the ultimate performance for specialty applications.

Ultimately, aligning the unique strengths of a ceramic with your specific engineering challenge is the key to a reliable and efficient heating system.

Summary Table:

| Ceramic Type | Key Properties | Common Applications |

|---|---|---|

| Aluminum Oxide (Alumina) | Excellent electrical insulation, high-temperature resistance | Supports and insulates metallic heating wires in cartridge/tubular heaters |

| Silicon Carbide (SiC) | High-temperature operation, wear and corrosion resistance | Self-heating elements in industrial furnaces |

| Silicon Nitride (Si3N4) | High mechanical strength, thermal shock resistance | Immersion heaters in molten metals, high-performance igniters |

| Zirconia (ZrO2) | Extreme mechanical strength at high temperatures, fracture toughness | Ultra-high-temperature furnaces, oxygen sensors |

| Cordierite | Low thermal expansion, superior thermal shock resistance | Infrared heater emitter plates, furnace supports for rapid cycling |

Need a custom high-temperature furnace solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced heating systems tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization capabilities to precisely match your experimental requirements. Contact us today to enhance your lab's efficiency and reliability with our expert solutions!

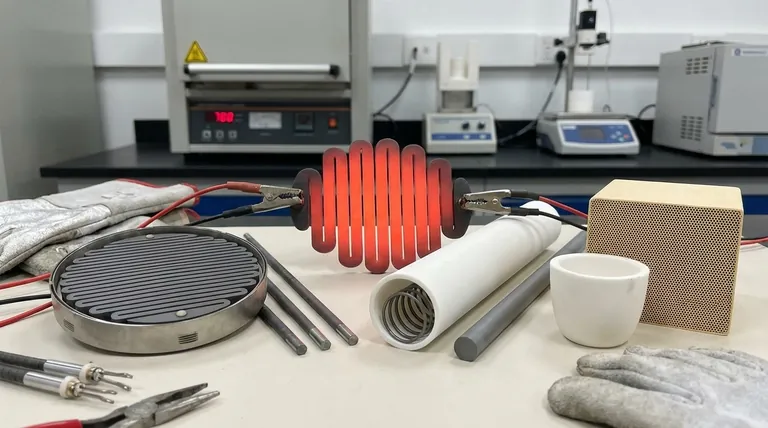

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is an 800°C thermal treatment required for M1/CeO2 catalysts? Master Atom Trapping for Superior Stability

- Can quartz tubes be customized for specific applications? Achieve Precise Control for High-Temperature Processes

- How do environmental factors affect heater material selection? Choose the Right Alloy for Your Industrial Heating Needs

- What are the characteristics and common uses of metal resistance heating elements? Discover Key Materials for Efficient Heat

- What are the maximum element temperatures for MoSi2 heating elements in different atmospheres? Optimize Your Furnace Performance

- Why are both external and internal thermocouples required for pyrolysis? Optimize Your Thermal Reaction Monitoring

- What are the common materials used for heating elements? Discover the Best Options for Your Heating Needs

- Why is it important to leave room for expansion and contraction in heating elements? Prevent Failure and Extend Lifespan