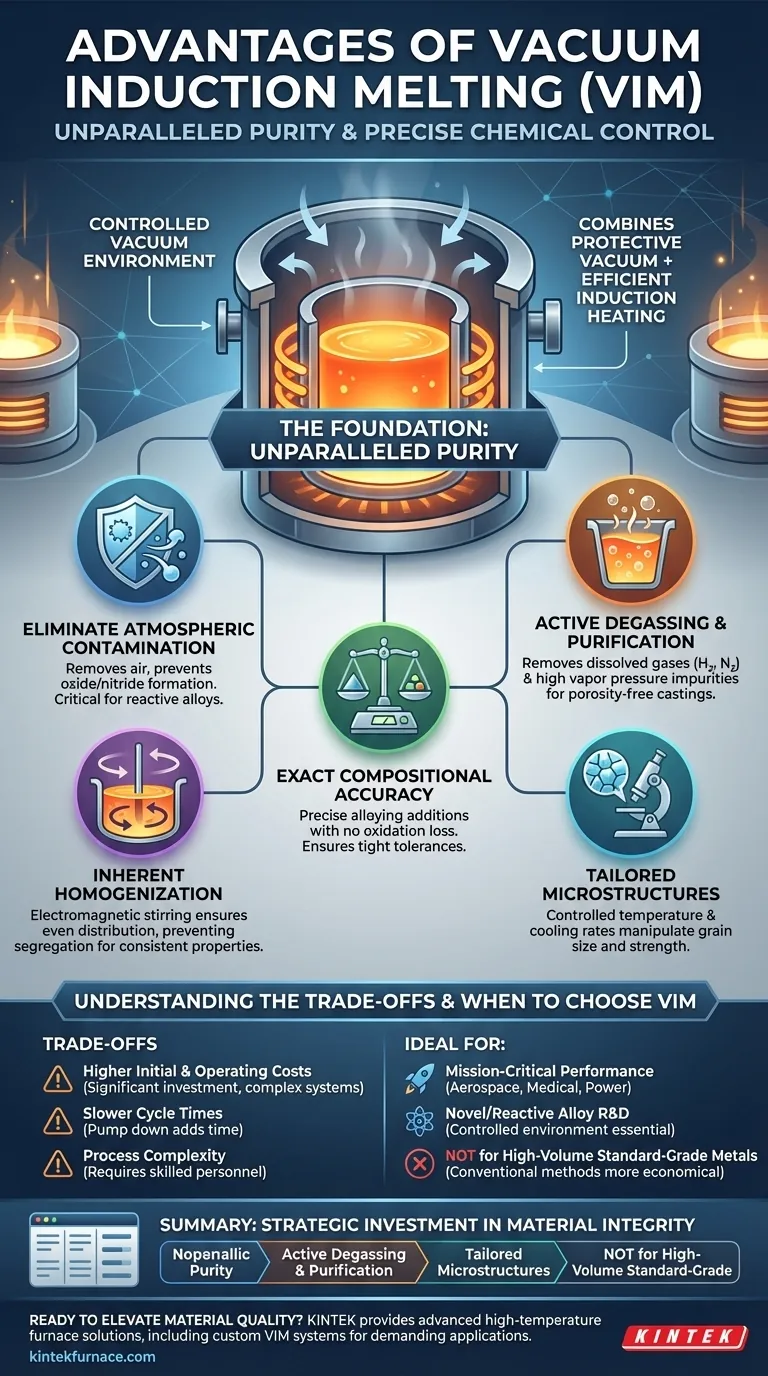

The primary advantage of Vacuum Induction Melting (VIM) is its unparalleled ability to produce alloys of extremely high purity and precise chemical composition. By performing the entire melting and casting process in a controlled vacuum, VIM eliminates contamination from atmospheric gases like oxygen and nitrogen, removes dissolved impurities, and provides precise control over the final material properties.

Conventional melting processes expose molten metal to the atmosphere, introducing impurities that compromise material integrity. Vacuum Induction Melting fundamentally solves this by combining the protective environment of a vacuum with the clean, efficient power of induction heating, resulting in the highest possible material quality.

The Foundation of VIM: Unparalleled Purity

The most significant benefits of VIM stem from its use of a vacuum. This controlled environment isn't just a passive shield; it actively refines the metal.

Eliminating Atmospheric Contamination

The vacuum chamber physically removes the air surrounding the metal charge. This prevents highly reactive molten metals from forming oxides and nitrides, which are brittle impurities that degrade mechanical properties like ductility and fatigue life.

This protection is critical for alloys based on elements like titanium, aluminum, and other reactive superalloys used in demanding applications.

Active Degassing and Purification

The low-pressure environment actively pulls dissolved gases, such as hydrogen and nitrogen, out of the molten bath. This degassing is essential for preventing porosity and hydrogen embrittlement in the final solidified casting.

Furthermore, the vacuum promotes the removal of undesirable trace elements with high vapor pressures, effectively boiling them out of the melt for an additional layer of purification.

Precision Control Over Chemistry and Structure

Beyond purity, VIM offers an exceptional degree of control over the entire metallurgical process, ensuring the final product meets exact specifications.

Exact Compositional Accuracy

In a VIM furnace, alloying elements can be added to the melt with extreme precision. Because there is no atmosphere to react with, valuable and reactive elements are not lost to oxidation.

This ensures the final chemical composition is tightly controlled within very close tolerances, which is a non-negotiable requirement for high-performance superalloys.

Inherent Homogenization

The electromagnetic field generated by the induction coil does more than just heat the metal. It also creates a natural, vigorous stirring action within the molten bath.

This electromagnetic stirring ensures all alloying elements are distributed evenly, preventing segregation and resulting in a completely homogenous final product with consistent properties throughout.

Tailored Microstructures

VIM systems provide precise control over both temperature and cooling rates. This allows metallurgists to manipulate the solidification process to achieve specific microstructures, directly influencing the material's final mechanical properties like grain size and strength.

Understanding the Trade-offs

While powerful, VIM is not the universal solution for all melting needs. Its advantages come with specific considerations.

Higher Initial and Operating Costs

VIM furnaces represent a significant capital investment compared to standard air-melt furnaces. The complexity of the vacuum systems, controls, and power supplies contributes to a higher operating cost per ton of metal produced.

Slower Cycle Times

The need to pump down the chamber to a deep vacuum before melting and carefully control the process adds time to each batch. This makes VIM inherently slower than continuous or large-scale air-melting operations.

Process Complexity

Operating a VIM furnace requires highly skilled personnel. Managing the interplay between the vacuum, temperature, power, and alloy additions is a complex task that demands significant training and expertise.

When to Choose Vacuum Induction Melting

Your decision to use VIM should be driven entirely by the required quality and performance of your final product.

- If your primary focus is mission-critical performance: For applications in aerospace, medical implants, or power generation turbines where material failure is not an option, the purity and reliability of VIM are essential.

- If your primary focus is developing novel or reactive alloys: The controlled environment of VIM is the only way to conduct research and development on materials that would be compromised by atmospheric exposure.

- If your primary focus is high-volume, standard-grade metals: The cost and complexity of VIM are unnecessary; conventional air-melting or AOD refining processes are far more economical.

Ultimately, choosing VIM is a strategic investment in achieving a level of material integrity that is simply not possible with any other method.

Summary Table:

| Advantage | Description |

|---|---|

| Unparalleled Purity | Eliminates atmospheric gases and impurities, preventing oxides and nitrides for superior material integrity. |

| Precise Chemical Control | Allows exact alloying element additions with no oxidation loss, ensuring tight compositional tolerances. |

| Homogeneous Structure | Electromagnetic stirring ensures even distribution of elements, preventing segregation. |

| Tailored Microstructures | Controlled temperature and cooling rates enable specific grain sizes and mechanical properties. |

| Active Degassing | Removes dissolved gases like hydrogen to prevent porosity and embrittlement in castings. |

Ready to elevate your material quality with Vacuum Induction Melting? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including custom VIM systems. Our expertise ensures precise control over purity and composition for demanding applications in aerospace, medical implants, and power generation. Contact us today to discuss how our tailored solutions can meet your unique experimental requirements and drive your success!

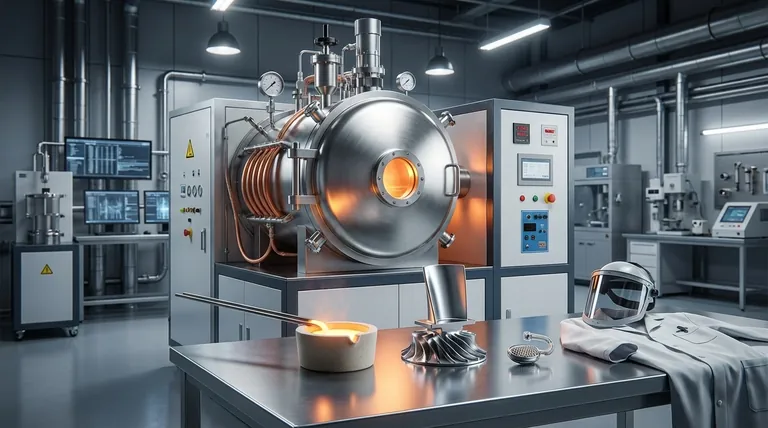

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys