In essence, the primary advantages of a vacuum annealing furnace stem from its ability to create a highly controlled, oxygen-free environment. This prevents surface oxidation and decarburization, leading to a superior material finish and purity that is impossible to achieve in a conventional furnace that heats in the presence of air or a less controlled atmosphere.

The choice between a vacuum and conventional annealing furnace is a fundamental trade-off. You are choosing between the exceptional surface quality and material purity of a vacuum process versus the potentially higher throughput and lower initial cost of a conventional system.

Superior Material Quality and Consistency

The core value of vacuum annealing is its impact on the final workpiece. The vacuum environment is not just an alternative heating method; it is an active part of the metallurgical process.

Preventing Oxidation and Decarburization

In a conventional furnace, the oxygen in the air reacts with the hot metal surface, creating a layer of oxide scale. This scale must often be removed through costly and time-consuming secondary processes like acid pickling or sandblasting.

A vacuum furnace removes virtually all oxygen, completely preventing this reaction. The result is a clean, bright, and scale-free surface right out of the furnace, preserving the integrity and dimensions of the part.

Achieving Uniform Heating

While conventional furnaces rely on convection (air movement) to transfer heat, a vacuum furnace relies almost exclusively on thermal radiation. In the absence of air, heat radiates directly and evenly to all exposed surfaces of the workpiece.

This eliminates hot spots and ensures exceptionally uniform temperature throughout the part, which is critical for effective and consistent stress relief and achieving the desired metallurgical properties.

Enhancing Mechanical Properties

By providing uniform heat and a controlled cooling cycle, a vacuum furnace allows for precise manipulation of a metal's microstructure. This results in more complete stress relief and improved properties like ductility and toughness, enhancing overall product quality and performance.

Precision, Efficiency, and Safety

Beyond material quality, vacuum furnaces offer significant operational advantages in control, cost, and workplace safety.

Unmatched Process Control

Modern vacuum furnaces are managed by sophisticated PLC and programmable controllers. This allows operators to define and execute highly precise, multi-stage heat treatment cycles automatically.

Every parameter—from the vacuum level to the heating ramp rate and cooling speed—is monitored and regulated in real-time. This ensures that every batch is processed with perfect repeatability, a level of precision that is difficult to match in conventional systems.

Improved Energy Efficiency

The vacuum itself is an excellent insulator. This means that very little heat energy is lost to the outside environment, concentrating the energy on the workpiece. This often leads to lower energy consumption per cycle compared to conventional furnaces that lose significant heat to escaping gases and through their walls.

Reduced Environmental Pollution

Conventional furnaces, especially those that are gas-fired, produce combustion byproducts. Atmosphere furnaces use protective gases that must be managed and vented. A vacuum furnace is an electrically heated, closed system that produces no emissions, making it a cleaner technology.

Understanding the Trade-offs

No technology is superior in all aspects. The decision to use a vacuum furnace requires acknowledging its specific operational characteristics.

The Challenge of Production Speed

A common point of confusion is processing time. While the heating elements in a vacuum furnace can be very responsive, the overall cycle time can be longer than in a conventional furnace.

The process steps of pumping down to the required vacuum level and, in some cases, backfilling with an inert gas for cooling, add time to each batch. For very large or high-volume parts, a continuous conventional furnace may offer higher overall throughput.

Higher Initial Investment

Vacuum furnaces are complex machines involving vacuum pumps, sealed chambers, and advanced control systems. This typically results in a higher initial purchase price and more complex maintenance requirements compared to simpler conventional furnace designs.

Inherent Safety Advantages

A vacuum furnace operates at negative pressure. This fundamentally eliminates the risk of explosion that exists with positive-pressure vessels or atmosphere furnaces using flammable gases like hydrogen. The low-oxygen environment also removes the risk of fire from the workpiece or internal materials.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on your process requirements and business goals.

- If your primary focus is surface finish and material purity: The oxidation prevention offered by a vacuum furnace is non-negotiable and provides a clear advantage.

- If your primary focus is high-volume, low-cost production of non-critical parts: A conventional furnace is often the more economical choice, provided that post-process surface cleaning is acceptable.

- If your primary focus is process repeatability for high-value components: The precise digital control of a vacuum furnace ensures that every part meets exact specifications, reducing scrap and ensuring reliability.

Ultimately, investing in a vacuum furnace is an investment in control, quality, and a pristine final product.

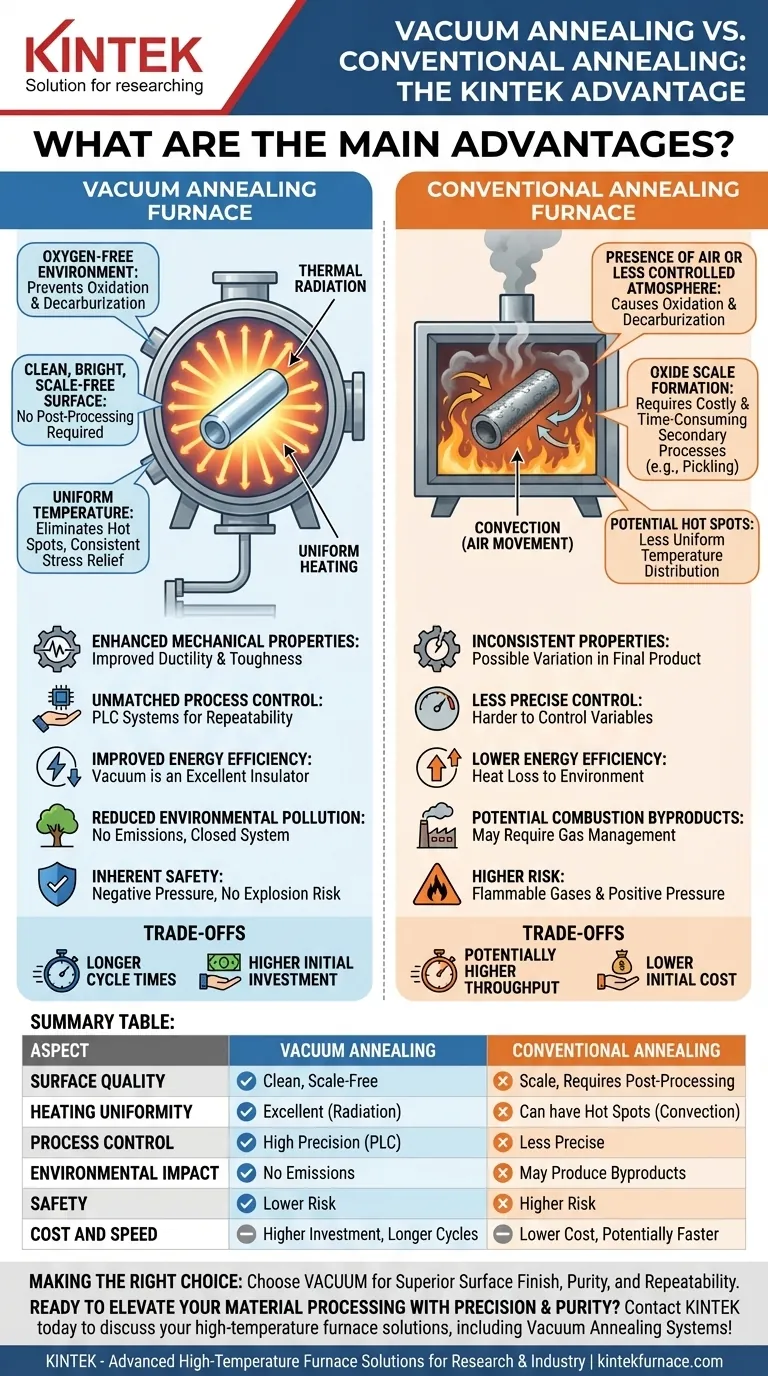

Summary Table:

| Aspect | Vacuum Annealing Furnace | Conventional Annealing Furnace |

|---|---|---|

| Surface Quality | Prevents oxidation and decarburization; clean, scale-free finish | Often requires post-processing for scale removal |

| Heating Uniformity | Excellent due to radiation-based heating in vacuum | Can have hot spots; relies on convection |

| Process Control | High precision with PLC systems; repeatable cycles | Less precise; harder to control variables |

| Environmental Impact | No emissions; cleaner operation | May produce combustion byproducts or require gas management |

| Safety | Lower risk of explosion and fire due to vacuum environment | Higher risk with flammable gases and positive pressure |

| Cost and Speed | Higher initial investment; longer cycle times | Lower cost; potentially higher throughput for large volumes |

Ready to elevate your material processing with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Our expertise in R&D and in-house manufacturing ensures you get reliable, custom-designed equipment—from Muffle and Tube Furnaces to Vacuum & Atmosphere Systems and CVD/PECVD setups. Whether you're in research, aerospace, or any field demanding superior metallurgical results, our vacuum annealing furnaces deliver unmatched quality and efficiency. Don't compromise on performance—contact us today to discuss how we can optimize your laboratory processes and drive your success!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion