The primary advantages of a channel induction furnace center on dramatic improvements in operational efficiency, material quality, and cost savings. This technology uses a highly controlled electromagnetic field to generate heat directly within the metal, leading to rapid melting, minimal waste, and a significantly more controlled and automated production environment compared to traditional methods.

A channel induction furnace is more than just a heating device; it is a precision tool that enhances manufacturing by delivering unparalleled control over temperature, reducing energy consumption, and improving the final quality of the metal itself.

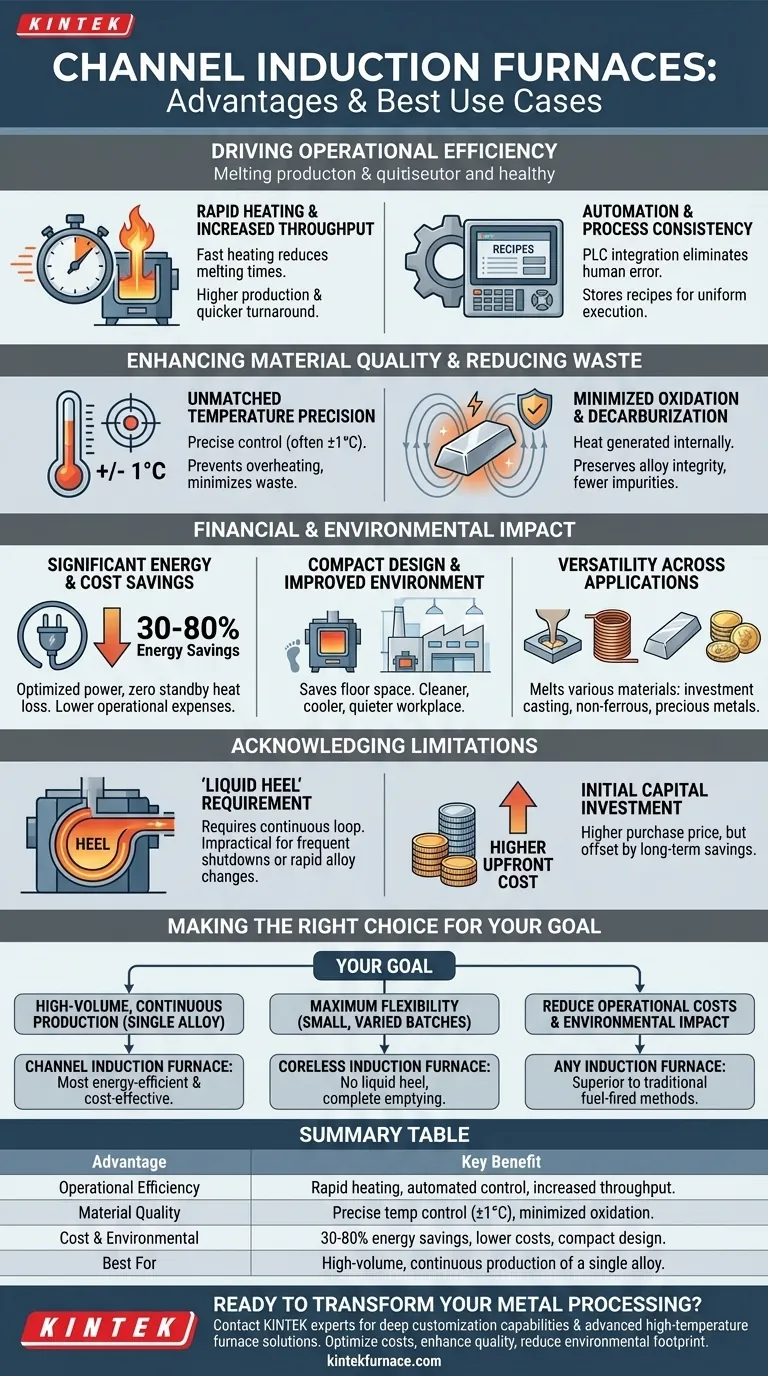

Driving Operational Efficiency

The core appeal of induction technology lies in its ability to streamline and accelerate the melting process. This efficiency is achieved through both speed and intelligent control.

Rapid Heating and Increased Throughput

High-frequency power generates heat instantly and directly within the conductive material. This fast heating speed drastically reduces melting times.

For industries like foundries and metal casting, this translates directly to higher production efficiency and quicker turnaround times on orders.

Automation and Process Consistency

Modern furnaces are integrated with Programmable Logic Controllers (PLCs). This enables the easy programming and storage of multiple "recipes" for different alloys and processes.

Automation ensures every batch is executed with the exact same parameters, eliminating human error and guaranteeing consistent performance. These systems also create detailed operational records for quality control analysis and reporting.

Enhancing Material Quality and Reducing Waste

Control is the defining characteristic of induction melting. By managing the process with high precision, you directly improve the metallurgical properties of the final product and minimize loss.

Unmatched Temperature Precision

Induction systems offer precise temperature control, often within ±1°C. This level of accuracy is critical for achieving specific, desired metal properties.

Accurate regulation prevents overheating, which minimizes material waste and ensures the final product meets stringent quality standards.

Minimized Oxidation and Decarburization

Because the heat is generated inside the metal rather than being applied from an external flame, there is significantly less oxidation and decarburization.

This preserves the integrity and composition of the alloy, resulting in a higher-quality, cleaner melt with fewer impurities to manage.

Understanding the Financial and Environmental Impact

The switch to induction technology has profound effects on a company's bottom line and its environmental footprint. These benefits are interconnected and create a strong business case.

Significant Energy and Cost Savings

Induction furnaces can offer 30–80% energy savings compared to traditional fuel-fired methods. This is due to optimized power control and zero heat loss during standby periods.

Furthermore, they eliminate the recurring costs and handling risks associated with purchasing fuel or consumable electrodes, directly lowering operational expenditures.

Compact Design and Improved Work Environment

These furnaces have a compact design, saving valuable floor space and potentially reducing facility operational costs.

By eliminating combustion, they create a much cleaner, cooler, and quieter work environment. This improves safety and employee morale without the need for extensive ventilation systems for exhaust fumes.

Versatility Across Applications

The technology is highly versatile, capable of melting a wide range of materials. Common applications include investment casting, copper and aluminum melting, precious metals processing, and the creation of highly uniform alloys.

Acknowledging the Limitations

To make an objective assessment, it's crucial to understand the specific operational context where a channel furnace excels and where it may be less suitable.

The "Liquid Heel" Requirement

A defining feature of a channel furnace is that it requires a continuous loop of molten metal—the "heel"—to maintain the electrical circuit. This makes it exceptionally efficient for continuous or semi-continuous operation with the same alloy.

However, this makes it impractical for operations that require frequent shutdowns, startups, or rapid changes between different types of alloys.

Initial Capital Investment

The initial purchase price of an induction furnace can be higher than some traditional furnace types. This upfront cost is typically offset over time by the significant energy and operational savings.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your specific production needs and business objectives.

- If your primary focus is high-volume, continuous production of a single alloy: A channel induction furnace is likely the most energy-efficient and cost-effective solution available.

- If your primary focus is maximum flexibility for small, varied batches: A coreless induction furnace may be a better choice, as it does not require a liquid heel and can be completely emptied between melts.

- If your primary focus is reducing operational costs and environmental impact: Any induction furnace offers a clear and significant advantage over traditional fuel-fired technologies.

Ultimately, choosing the right technology is about aligning the equipment's inherent strengths with your operational goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Operational Efficiency | Rapid heating, automated control, and increased throughput |

| Material Quality | Precise temperature control (±1°C), minimized oxidation |

| Cost & Environmental | 30-80% energy savings, lower operational costs, compact design |

| Best For | High-volume, continuous production of a single alloy |

Ready to transform your metal processing with superior efficiency and quality?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our expertise in induction heating technology, including Channel and Coreless Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique production requirements—whether for investment casting, non-ferrous metal melting, or precious metals processing.

Contact our experts today to discuss how a custom induction furnace solution can optimize your operational costs, enhance product quality, and reduce your environmental footprint.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance