At its core, a muffle furnace offers three primary advantages: exceptional temperature control, a contamination-free heating environment, and operational reliability. These furnaces achieve very high, uniform temperatures while isolating the sample from the heating elements, ensuring both process precision and material purity.

The true value of a muffle furnace isn't just its ability to get hot, but its ability to create a highly controlled and clean high-temperature environment. This isolation is what enables repeatable, reliable results for sensitive scientific and industrial processes.

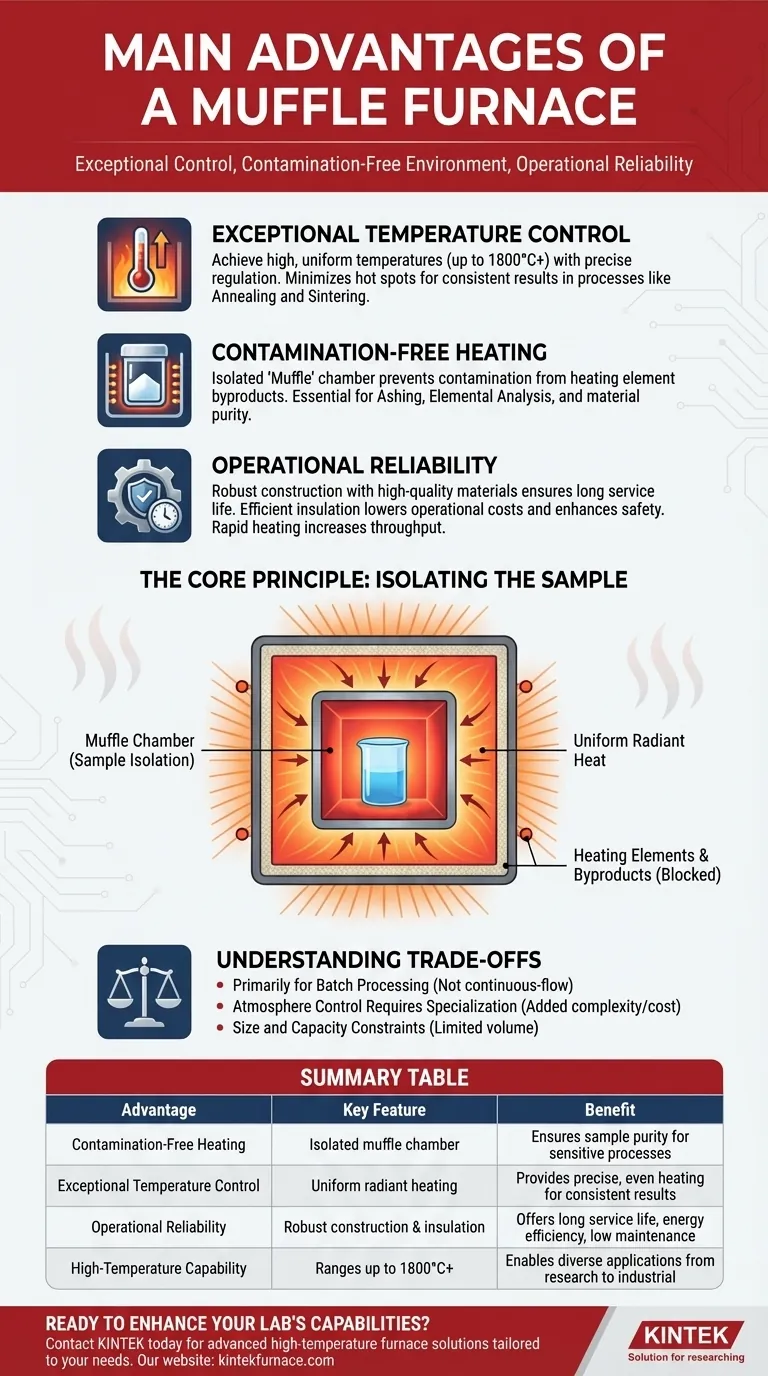

The Core Principle: Isolating the Sample for Purity

The defining feature of this equipment is the muffle—an isolated inner chamber that separates your sample from the heating elements and their byproducts. This design is the source of its most significant advantages.

How the "Muffle" Prevents Contamination

The chamber acts as a physical barrier. This prevents particles or gases from the heating elements (common in fuel-fired furnaces or when elements degrade) from contaminating the material being processed.

This is critical for applications like ashing, elemental analysis, or any process where sample purity is paramount.

Achieving Exceptional Temperature Uniformity

By heating the exterior of the muffle, the furnace radiates heat inward evenly from all sides. This design minimizes hot spots and ensures the entire sample experiences the same temperature.

This temperature uniformity is essential for heat treatment processes like annealing and sintering, where consistent material properties depend on even heating.

Unlocking High-Temperature Processes

Muffle furnaces are engineered to safely reach and sustain very high temperatures, often ranging from 200°C up to 1300°C, with specialized models exceeding 1800°C.

This capability allows for a wide range of applications, from producing low-carbon steel and copper to advanced materials research.

The Engineering Behind Reliability and Efficiency

Beyond the core principle of the muffle, these furnaces are built for practical, long-term use in demanding environments.

Robust Construction for Long-Term Durability

Manufacturers use high-quality, heat-resistant materials and robust construction methods. This results in a long service life and resistance to oxidation and corrosion.

The durability translates directly into a lower total cost of ownership due to reduced maintenance and replacement needs.

Insulation and Energy Efficiency

Modern muffle furnaces use highly effective insulation to minimize heat loss to the surrounding environment. This not only improves energy efficiency and lowers operational costs but also enhances safety by keeping the exterior surfaces cooler.

Compared to less insulated or conventional heating methods, this efficiency is a significant operational advantage.

Rapid Heating for Increased Throughput

Many models are designed for quick heating, often reaching their maximum temperature in about an hour. This rapid heat-up time saves valuable lab or production time, increasing sample throughput and overall efficiency.

Understanding the Trade-offs

While highly advantageous, muffle furnaces are not the universal solution for all heating needs. Understanding their limitations is key to making an informed decision.

Primarily for Batch Processing

A standard muffle furnace is designed for batch processing, where you load a sample, run the heating cycle, and then remove it. They are not suited for continuous-flow production lines.

Atmosphere Control Requires Specialization

While a standard furnace operates with air, creating a specific atmosphere (e.g., with nitrogen or hydrogen) requires a specialized, sealed-muffle furnace with gas inlets. This adds complexity and cost.

Size and Capacity Constraints

Most lab-scale muffle furnaces have a limited internal volume. While larger industrial models exist, they cannot match the massive throughput of continuous or belt furnaces used in large-scale manufacturing.

Making the Right Choice for Your Application

Selecting the right equipment depends entirely on your primary goal.

- If your primary focus is analytical purity (e.g., ashing, trace metal analysis): The muffle's ability to prevent sample contamination from heating elements is its most critical advantage.

- If your primary focus is materials science (e.g., annealing, sintering): The combination of precise temperature control and exceptional uniformity is essential for achieving desired material properties.

- If your primary focus is operational efficiency and cost: The furnace's durable construction, energy-efficient design, and low maintenance needs provide a low total cost of ownership over its long service life.

Ultimately, a muffle furnace is the superior choice when your process demands a pure, precise, and repeatable high-temperature environment.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| Contamination-Free Heating | Isolated muffle chamber | Ensures sample purity for sensitive processes like ashing and analysis |

| Exceptional Temperature Control | Uniform radiant heating | Provides precise, even heating for consistent results in annealing and sintering |

| Operational Reliability | Robust construction and insulation | Offers long service life, energy efficiency, and low maintenance costs |

| High-Temperature Capability | Ranges up to 1800°C+ | Enables diverse applications from materials research to industrial processing |

Ready to enhance your lab's capabilities with a reliable, high-performance furnace?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're focused on purity, precision, or efficiency, we can help you achieve superior results.

Contact us today to discuss how our furnaces can benefit your specific applications and drive your success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis