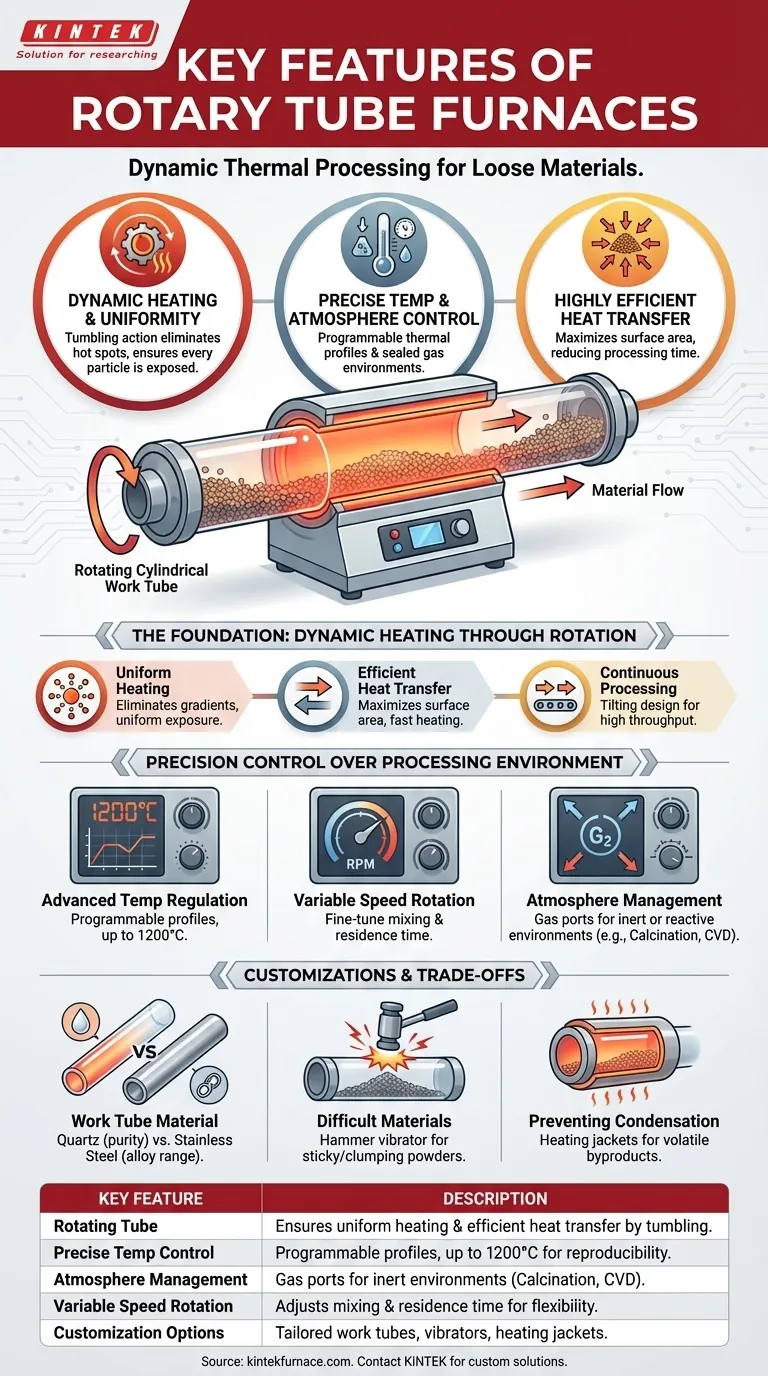

At their core, rotary tube furnaces are defined by three key features: a rotating cylindrical work tube, precise temperature and atmosphere control systems, and a design that promotes highly efficient heat transfer. This combination allows for the dynamic and uniform thermal processing of loose materials like powders and granules, which is difficult to achieve in a static furnace.

The central advantage of a rotary tube furnace isn't just one feature, but how they work in concert. The rotation guarantees uniform heating, while advanced controllers allow you to precisely manage the thermal profile and atmosphere, creating a highly reproducible processing environment.

The Foundation: Dynamic Heating Through Rotation

The defining characteristic of this furnace type is its ability to tumble the material during heating. This mechanical action is the source of its primary benefits.

How Rotation Creates Uniformity

By continuously rotating, the furnace ensures that every particle of the material is exposed to the heat source and the surrounding atmosphere. This tumbling motion eliminates hot spots and temperature gradients common in static batch processing, leading to exceptionally uniform heating.

Achieving Efficient Heat Transfer

The constant mixing action maximizes the surface area of the material being heated. This results in very efficient and rapid heat transfer, reducing the overall time required to bring the entire batch to the desired temperature.

Enabling Continuous Processing

Many rotary tube furnaces are designed to be tilted, allowing material to be fed into one end and continuously discharged from the other. This capability is ideal for continuous batch processing in industrial settings, minimizing material handling and increasing throughput.

Precision Control Over the Processing Environment

Beyond the mechanical rotation, these furnaces provide sophisticated control over every critical process parameter.

Advanced Temperature Regulation

Modern rotary tube furnaces feature advanced digital controllers. These systems offer programmable thermal profiles, often with dozens of segments to manage heating rates, dwell times, and cooling rates.

They utilize high-quality heating elements and ceramic fiber insulation to achieve high efficiency and operating temperatures up to 1200°C (2192°F).

Variable Speed Rotation

The rotational speed is typically managed by a DC variable speed control. Adjusting the speed allows you to fine-tune the degree of mixing and, in continuous systems, control the material's residence time within the hot zone.

Atmosphere Management

For sensitive applications like calcination or chemical vapor deposition (CVD), controlling the gas environment is critical. These furnaces can be equipped with gas inlet and outlet ports (e.g., 1/4" inert gas in, KF25 outgassing) to maintain a specific atmosphere, such as an inert gas environment, or to effectively remove reaction byproducts.

Understanding the Customizations and Trade-offs

A rotary tube furnace is not a one-size-fits-all solution. Its components are chosen based on the specific application, each with its own implications.

Work Tube Material and Design

The choice of work tube is critical. Quartz tubes are common for their high purity and thermal shock resistance, while stainless steel and other alloys are used for different temperature ranges or when quartz is chemically unsuitable. The size and shape can be customized for specific capacity needs.

Handling Difficult Materials

Standard tumbling is not effective for all materials. For high-viscosity or sticky organic powders, an optional hammer vibrator can be added to the tube to prevent clumping and ensure proper flow.

Preventing Condensation

When processing materials that release volatile byproducts like tar, heating jackets can be fitted on the ends of the furnace. These prevent condensation in cooler zones, which could otherwise clog the system.

Making the Right Choice for Your Application

Selecting the right features depends entirely on your primary processing goal.

- If your primary focus is maximum process uniformity: Prioritize a system with a high-quality, programmable temperature controller and variable speed rotation to ensure every particle experiences the exact same conditions.

- If your primary focus is high-throughput production: Seek a furnace designed for continuous operation with a tilting mechanism and robust material handling capabilities.

- If your primary focus is sensitive atmospheric control: Ensure the model has sealed flanges and the necessary gas ports to manage your specific inert gas or vacuum requirements.

- If your primary focus is processing challenging materials: Inquire about specialized options like hammer vibrators for sticky powders or heated jackets for materials that produce condensable byproducts.

Ultimately, understanding these key features empowers you to configure a rotary tube furnace that perfectly matches your material and process requirements.

Summary Table:

| Key Feature | Description |

|---|---|

| Rotating Tube | Ensures uniform heating and efficient heat transfer by tumbling materials like powders and granules. |

| Precise Temperature Control | Programmable thermal profiles with digital controllers, operating up to 1200°C for reproducible results. |

| Atmosphere Management | Gas inlet/outlet ports for inert environments, ideal for calcination and CVD processes. |

| Variable Speed Rotation | DC control adjusts mixing and residence time, enhancing process flexibility. |

| Customization Options | Includes work tube materials (e.g., quartz, stainless steel), hammer vibrators, and heating jackets for specific needs. |

Ready to optimize your material processing with a tailored rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your lab's efficiency and throughput!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary kilns demonstrate energy efficiency? Maximize Heat Transfer and Fuel Flexibility

- How do advanced mixing and conveying technologies improve rotary furnace performance? Boost Efficiency and Uniformity

- What are the advantages of rotary tube furnaces in fuel compatibility? Boost Efficiency and Cut Costs

- What are the advantages of a rotary tube furnace for activated carbon? Achieve Dynamic Homogeneity and Pore Control

- What types of atmospheres can a rotary furnace operate in and why is this important? Unlock Precise Material Processing

- What are the two main types of rotary kilns based on their heating method? Direct vs. Indirect Firing Explained

- Why is understanding the core features of a rotary furnace important for engineers and professionals? Unlock Efficient Material Processing

- Why are rotary furnaces particularly suitable for aluminum melting and scrap recycling? Boost Your Metal Recovery Efficiency