For optimal results, a modern zirconia sintering furnace must combine precise temperature control, high-purity heating elements, and intelligent programming. These features work in concert to ensure the final restoration achieves its target strength, translucency, and dimensional accuracy without contamination or defects. Advanced models also integrate features like controlled cooling, vacuum atmospheres, and fast-sintering cycles to improve both the quality of the final product and the efficiency of the dental lab workflow.

The key shift in furnace technology is from simple heating ovens to sophisticated process controllers. Modern furnaces are not just about reaching a target temperature; they are about precisely managing the entire thermal journey of the zirconia—from heating to holding to cooling—to guarantee predictable and repeatable clinical outcomes.

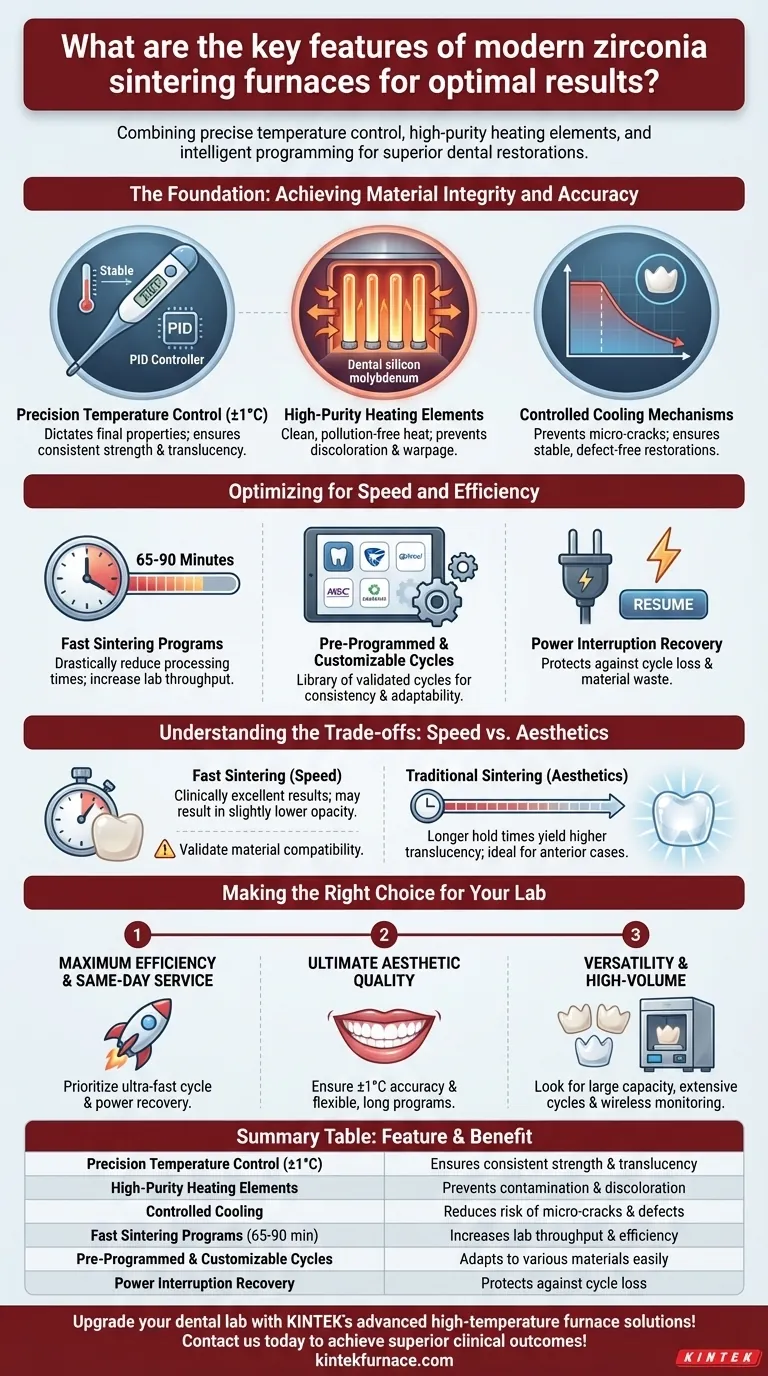

The Foundation: Achieving Material Integrity and Accuracy

The primary function of a sintering furnace is to transform a chalky, milled zirconia blank into a dense, strong, and stable final restoration. Achieving this requires an environment of extreme control.

Precision Temperature Control

The most critical feature is the ability to maintain exact temperatures. Modern furnaces use Proportional-Integral-Derivative (PID) controllers to achieve an accuracy of ±1℃.

This precision is not a luxury; it directly dictates the final properties of the zirconia. Even minor deviations can negatively impact the material's translucency and flexural strength.

High-Purity Heating Elements

Contamination is a significant risk during sintering. High-purity dental silicon molybdenum heating elements are the industry standard for a reason.

They provide clean, pollution-free heat, preventing discoloration of the restoration. Furthermore, they are designed to distribute heat evenly throughout the chamber, which is crucial for preventing warpage and ensuring the entire restoration sinters uniformly.

Controlled Cooling Mechanisms

How a restoration cools is just as important as how it is heated. Rapid, uncontrolled cooling can induce thermal shock, leading to micro-cracks that compromise the long-term durability of the crown or bridge.

Modern furnaces incorporate automated, controlled cooling functions. These gradually lower the temperature at a pre-determined rate, preventing internal stresses and ensuring a stable, defect-free final product.

Optimizing for Speed and Efficiency

In a modern dental lab, time is a critical resource. Furnace technology has evolved to drastically reduce processing times without sacrificing quality, enabling more efficient workflows and even same-day restorations.

Fast Sintering Programs

The most significant workflow enhancement is the development of fast sintering cycles. Certain furnaces can now complete a full sintering process in as little as 65 to 90 minutes, compared to the many hours required by traditional cycles.

This feature allows labs to dramatically increase throughput and offer faster turnaround times to clinicians.

Pre-Programmed & Customizable Cycles

Zirconia is not a single material; there are many variations with unique sintering requirements. A key feature is a library of pre-programmed cycles validated for specific materials from major manufacturers.

This ensures consistency and eliminates the guesswork. The ability to also create and save custom programs provides the flexibility needed to adapt to new materials as they come to market.

Power Interruption Recovery

A power outage during a multi-hour sintering cycle can result in a total loss of the restorations inside. High-end furnaces now include a memory function that allows the cycle to resume exactly where it left off once power is restored.

This is a crucial safety net that protects against the loss of valuable time, labor, and materials.

Understanding the Trade-offs: Speed vs. Aesthetics

While fast sintering is a powerful feature, it is essential to understand its implications. The choice between a fast cycle and a traditional, slower cycle involves a direct trade-off.

The Impact on Translucency

Generally, slower sintering cycles with longer hold times yield higher translucency. This is because it allows more time for the material's crystalline structure to fully form and densify, which enhances light transmission.

For highly aesthetic anterior cases where maximal translucency is the primary goal, a traditional, slower cycle is often the superior choice. Fast sintering, while producing clinically excellent results, may result in slightly lower opacity values.

Material Compatibility

It is critical to recognize that not all zirconia materials are validated for fast sintering. Using a fast cycle on a material not specifically designed for it can lead to suboptimal strength, poor aesthetics, and potential restoration failure. Always follow the zirconia manufacturer's specific recommendations.

Making the Right Choice for Your Lab

Selecting the right furnace depends on a clear understanding of your lab's primary business and clinical goals.

- If your primary focus is maximum efficiency and same-day service: Prioritize a furnace with a proven, ultra-fast sintering cycle and a reliable power-interruption recovery feature.

- If your primary focus is ultimate aesthetic quality for anterior cases: Ensure the furnace offers exceptional temperature accuracy (±1℃) and the flexibility of long, slow, customizable programs.

- If your primary focus is versatility for a high-volume lab: Look for a unit with a large chamber capacity, a comprehensive library of pre-programmed cycles, and wireless connectivity for remote monitoring.

Ultimately, investing in a furnace with these advanced features is an investment in predictable, high-quality outcomes for your lab and your patients.

Summary Table:

| Feature | Benefit |

|---|---|

| Precision Temperature Control (±1℃) | Ensures consistent strength and translucency |

| High-Purity Heating Elements | Prevents contamination and discoloration |

| Controlled Cooling | Reduces risk of micro-cracks and defects |

| Fast Sintering Programs (65-90 min) | Increases lab throughput and efficiency |

| Pre-Programmed & Customizable Cycles | Adapts to various zirconia materials easily |

| Power Interruption Recovery | Protects against cycle loss and material waste |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for optimal zirconia sintering results. Contact us today to enhance your workflow and achieve superior clinical outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision