In essence, rotary retort furnaces are ideal for the uniform, continuous heat treatment of small, discrete parts or granular materials. Their core applications include critical processes like quench hardening, tempering, annealing, and calcining, where consistency across a large volume of material is the primary goal.

The true value of a rotary retort furnace lies in its ability to combine a sealed, controlled atmosphere with continuous, gentle tumbling. This unique pairing ensures every single part or particle receives identical heat treatment, eliminating inconsistencies common in static batch processes.

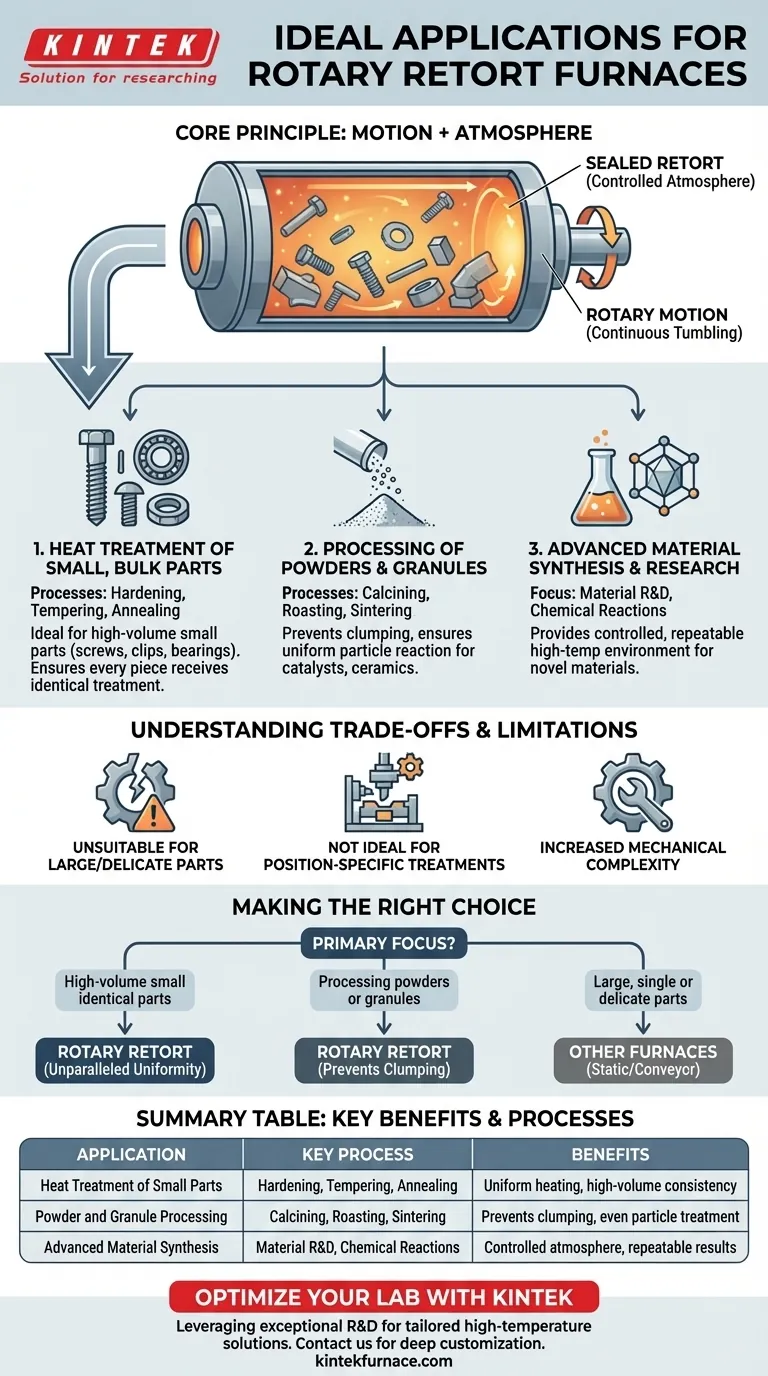

The Core Principle: Combining Motion and Atmosphere

To understand the ideal applications for a rotary retort furnace, you must first grasp its two defining features: the sealed retort and the rotary motion. It is the synergy between these two elements that unlocks its capabilities.

How Rotary Action Ensures Uniformity

The furnace's cylindrical retort rotates slowly, causing the parts or materials inside to gently tumble.

This continuous movement exposes all surfaces of every piece to the heat source and the controlled atmosphere evenly. It prevents parts in the middle of a load from being insulated by those on the outside, a common problem in static furnaces.

The Role of the Sealed Retort

The "retort" is a high-temperature alloy tube or chamber that is sealed from the outside environment.

This seal allows for precise control over the internal atmosphere. You can introduce inert gases to prevent oxidation, or reactive gases to induce specific surface chemistry changes, like in carburizing or nitriding.

Key Industrial Applications Breakdown

The combination of uniform heating and atmospheric control makes the rotary retort furnace a specialist for several key industrial processes.

Heat Treatment of Small, Bulk Parts

This is the most common application. Processes like hardening, tempering, and annealing require precise temperature control to achieve desired metallurgical properties.

Rotary retorts are perfect for high-volume parts like fasteners, bearings, clips, and ammunition casings. The tumbling action ensures that every single piece achieves the exact same hardness and microstructure.

Processing of Powders and Granules

When heating powders or granular materials, clumping and uneven reactions are major concerns.

The rotary furnace excels at processes like calcining, roasting, and sintering of ceramic or metal powders. The gentle tumbling prevents agglomeration and guarantees that every particle is processed uniformly, which is vital in catalyst production and the creation of materials like alumina or iron ore pellets.

Advanced Material Synthesis and Research

In research and development, creating novel materials often requires high temperatures and very specific atmospheric conditions.

Rotary retort furnaces provide the controlled, repeatable environment necessary for material synthesis, high-temperature chemical reaction experiments, and the development of advanced composites and alloys.

Understanding the Trade-offs

While highly effective, a rotary retort furnace is not a universal solution. Its specific design creates clear limitations.

Unsuitable for Large or Delicate Parts

The tumbling motion that ensures uniformity can also cause damage. Large, heavy parts would damage the retort, while delicate components with fine features could be broken or tangled during processing.

Not Ideal for Position-Specific Treatments

Processes that require a part to be held in a specific orientation, such as furnace brazing of a complex assembly, are not compatible with a rotary retort. These applications demand a static furnace.

Increased Mechanical Complexity

The rotary mechanism, including the drive system and seals, adds mechanical complexity compared to a simple box furnace. This can translate to higher initial costs and more demanding maintenance schedules.

Making the Right Choice for Your Process

Selecting the correct furnace technology comes down to the nature of your parts and your primary processing objective.

- If your primary focus is high-volume heat treatment of small, identical parts (like screws or bearings): The rotary retort is likely the ideal choice for its unparalleled uniformity and efficiency.

- If your primary focus is processing powders or granular materials (like catalysts or ores): The gentle tumbling action makes this furnace superior for preventing clumping and ensuring consistent chemical reactions.

- If your primary focus is treating large, single components or extremely delicate parts: You should explore other options like static batch or conveyor belt furnaces, as the tumbling action is unsuitable.

Understanding this core principle of motion-driven uniformity is the key to leveraging the right furnace technology for your specific material processing goals.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Heat Treatment of Small Parts | Hardening, Tempering, Annealing | Uniform heating, high-volume consistency |

| Powder and Granule Processing | Calcining, Roasting, Sintering | Prevents clumping, even particle treatment |

| Advanced Material Synthesis | Material R&D, Chemical Reactions | Controlled atmosphere, repeatable results |

Optimize your lab's heat treatment processes with KINTEK's advanced rotary retort furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and consistency. Contact us today to discuss how our furnaces can enhance your material processing!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing