In short, a muffle furnace is specifically designed for high-temperature applications, with a typical operating range between 500°C and 1800°C (932°F to 3272°F). The exact maximum temperature a specific furnace can achieve is highly dependent on its model, construction, and heating method.

The key takeaway is that while many muffle furnaces can reach extremely high temperatures, the crucial factor isn't just the peak number. It's understanding how the furnace's design—from its insulation to its heating elements—dictates its capabilities and suitability for your specific application.

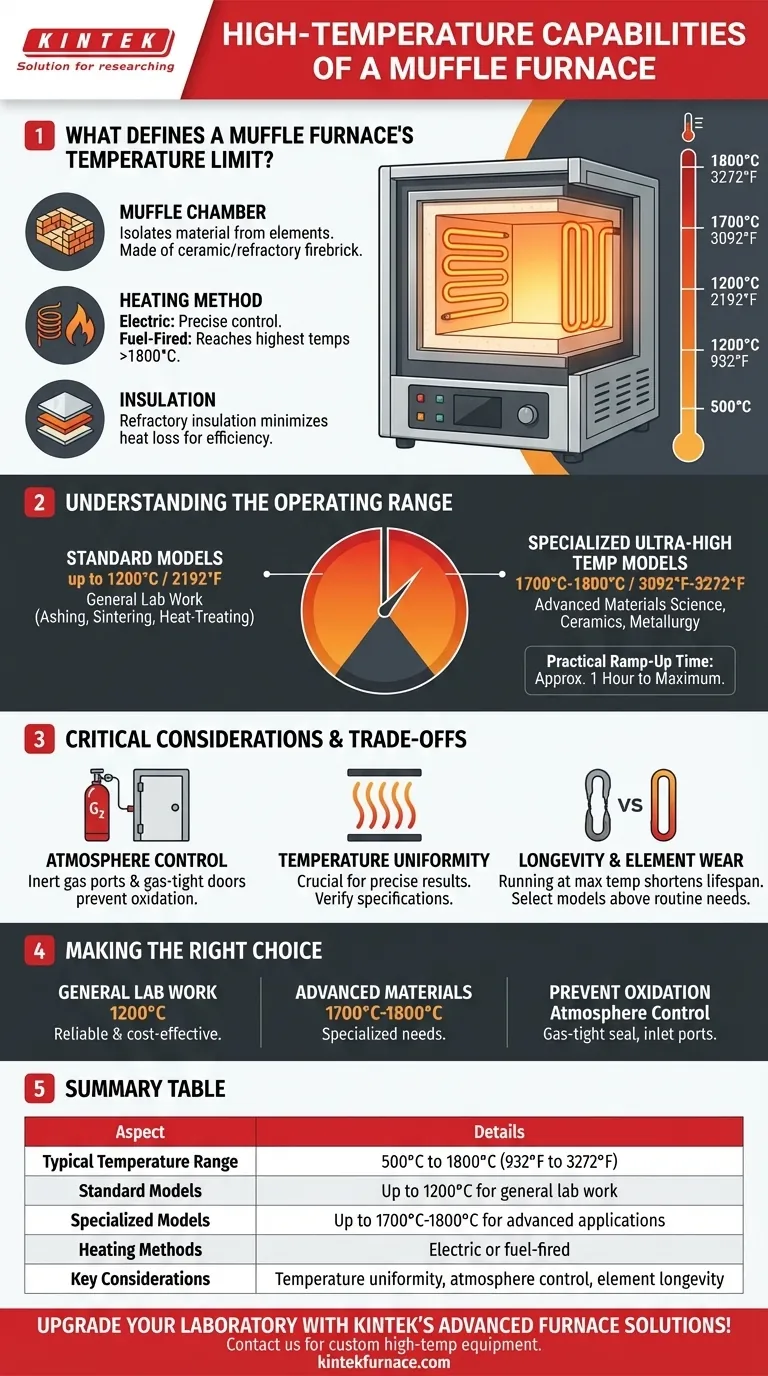

What Defines a Muffle Furnace's Temperature Limit?

A muffle furnace achieves high temperatures through a combination of powerful heating and robust insulation. The interplay of these components determines its ultimate performance ceiling.

The Core Component: The Muffle Chamber

The defining feature is the muffle, an inner chamber that isolates the material being heated from the heating elements. This prevents contamination and ensures a more controlled environment.

This chamber is constructed from highly heat-resistant materials like ceramic or refractory firebrick, which can withstand extreme thermal stress without degrading.

Heating Method: Electric vs. Fuel-Fired

Most modern lab-scale muffle furnaces are electric, using high-resistance elements to generate heat. These are valued for their precise temperature control.

Larger, industrial-scale furnaces can be heated by natural gas, propane, or oil. These fuel-fired models can often reach the highest temperatures, sometimes exceeding 1800°C.

The Role of Insulation

The furnace body is lined with layers of refractory insulation. This material is critical for minimizing heat loss, which allows the furnace to reach and maintain its target temperature efficiently and safely.

Understanding the Operating Range

Not all muffle furnaces are created equal. They are typically categorized by their maximum sustainable temperature, which directly relates to their intended use.

Standard High-Temperature Models

A large number of general-purpose muffle furnaces operate up to a maximum of 1200°C (2192°F). This is sufficient for many common laboratory applications like ashing, sintering, and heat-treating metals.

Specialized Ultra-High Temperature Models

For more demanding applications in materials science, ceramics, or metallurgy, specialized furnaces are required. These models can reliably reach 1700°C to 1800°C (3092°F to 3272°F) or even higher.

Practical Ramp-Up Time

Reaching these extreme temperatures is not instantaneous. On average, a muffle furnace requires about one hour to heat up from ambient to its maximum operating temperature, though this varies with the size and power of the unit.

Critical Considerations and Trade-offs

Choosing a furnace based on maximum temperature alone can lead to poor results. You must consider the practical realities of your process.

Atmosphere Control

Many high-temperature processes are sensitive to oxygen. If you need to prevent oxidation, look for furnaces equipped with gas-tight doors and ports that allow for the introduction of an inert gas, creating a positive pressure environment.

Temperature Uniformity

A high maximum temperature is meaningless if the heat isn't evenly distributed. For precise work, temperature uniformity across the entire chamber is a critical specification to verify.

Longevity and Element Wear

Consistently operating a furnace at its absolute maximum temperature will shorten the lifespan of its heating elements and insulation. It is often wise to select a model with a maximum temperature slightly higher than your routine operating needs.

Making the Right Choice for Your Application

To select the correct furnace, you must align its capabilities with your primary goal.

- If your primary focus is general lab work like ashing or basic heat treating: A standard furnace with a maximum temperature of 1200°C is typically a reliable and cost-effective choice.

- If your primary focus is advanced materials science or working with high-melting-point ceramics: You will need a specialized furnace capable of reaching 1700°C to 1800°C.

- If your primary focus is preventing oxidation or material reaction: Prioritize a furnace with excellent atmospheric control features, such as a gas-tight seal and inlet ports.

Ultimately, your decision should be guided by a clear understanding of your process requirements, not just the pursuit of the highest possible temperature.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Temperature Range | 500°C to 1800°C (932°F to 3272°F) |

| Standard Models | Up to 1200°C for general lab work (e.g., ashing, sintering) |

| Specialized Models | Up to 1700°C-1800°C for advanced applications (e.g., ceramics, metallurgy) |

| Heating Methods | Electric (precise control) or fuel-fired (higher temperatures) |

| Key Considerations | Temperature uniformity, atmosphere control, element longevity |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precise heating equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for optimal performance and efficiency. Contact us today to discuss how we can support your high-temperature applications and enhance your research outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment