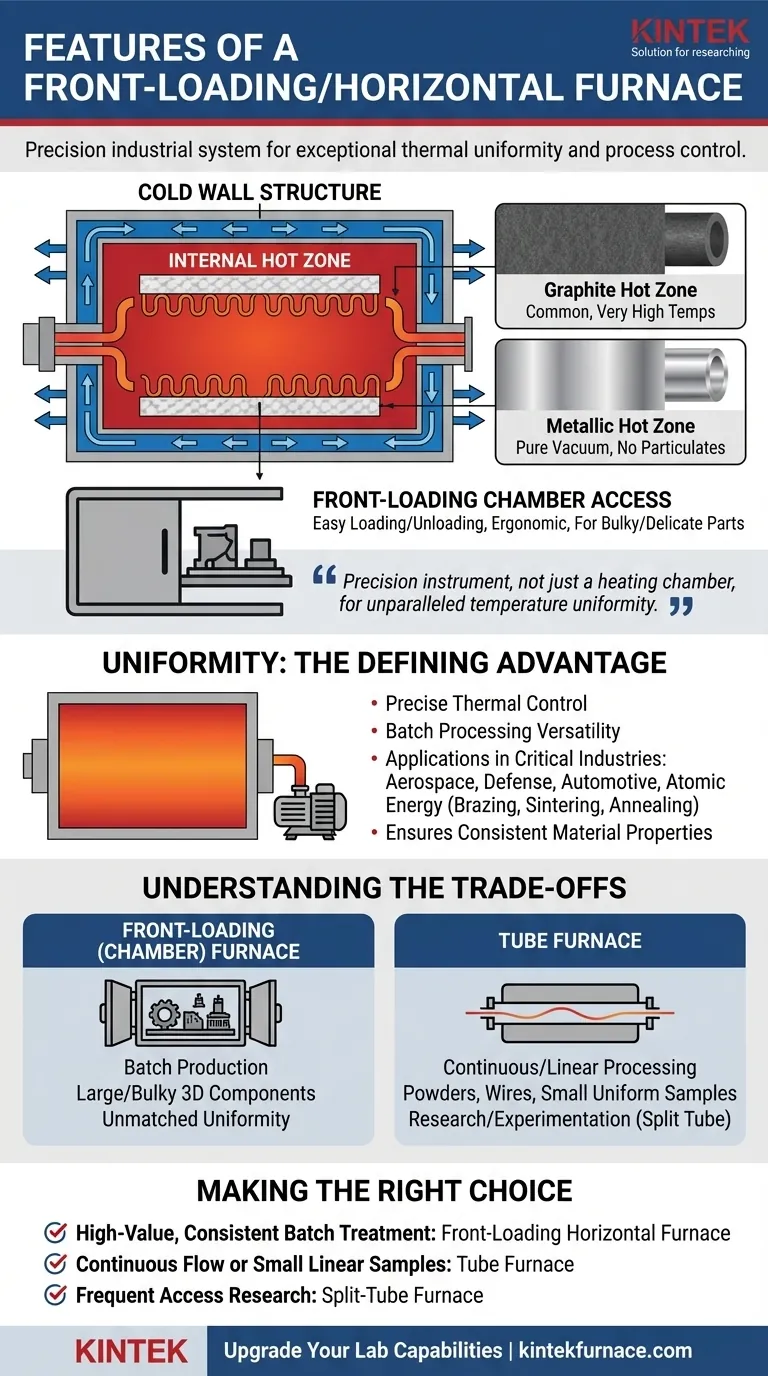

At its core, a front-loading horizontal furnace is an industrial or laboratory system designed for exceptional thermal uniformity and precise process control. It features a sturdy, externally-cooled "cold wall" structure, an internal heating "hot zone" made of either graphite or metallic elements, and sliding front doors for easy loading and unloading of parts. This design is specifically engineered for high-value vacuum heat treatment processes.

A front-loading horizontal furnace is not just a heating chamber; it is a precision instrument. Its defining characteristic is its ability to deliver unparalleled temperature uniformity across a large volume, making it essential for treating critical components where material integrity cannot be compromised.

Deconstructing the Core Design

To understand why this furnace is favored in demanding industries, we must look at its fundamental components and how they work together.

The Cold Wall Structure

The furnace body is a "cold wall" vessel, meaning the outer structure is actively cooled, typically with water. This design serves two critical functions.

First, it maintains the structural integrity of the furnace under extreme internal temperatures. Second, it isolates the heating process, ensuring that heat is precisely contained within the designated hot zone.

The Internal Hot Zone (Graphite vs. Metallic)

Inside the cold wall is the hot zone, which contains the heating elements and insulation. This zone is typically constructed from one of two materials.

Graphite hot zones are common and can reach very high temperatures, making them suitable for a wide range of processes. Metallic hot zones (often molybdenum or tungsten) are used in applications requiring an extremely clean, pure vacuum environment, as they do not produce the fine particulates associated with graphite.

Front-Loading Chamber Access

The horizontal orientation and large, sliding front doors are a key ergonomic and process-driven feature. This configuration allows for straightforward loading and unloading of parts, often with a dedicated charging car or automated system.

This is especially practical for heavy, delicate, or numerous parts that need to be arranged carefully within the chamber to ensure optimal exposure to heat.

Why Uniformity Is the Defining Advantage

While many furnaces can get hot, the horizontal front-loader's primary purpose is to do so with exceptional uniformity.

Achieving Precise Thermal Control

The large, open chamber design, combined with a powerful vacuum system and advanced temperature controllers, allows for the entire workload to be heated and cooled at a precisely managed rate. This eliminates hot or cold spots that could create weak points or inconsistent material properties.

As a type of batch furnace, it is highly versatile, capable of running different customizable heating and cooling profiles for various materials and component sizes.

Applications in Critical Industries

This level of control is non-negotiable in sectors like aerospace, defense, automotive, and atomic energy. In these fields, heat treatment processes like brazing, sintering, or annealing must produce parts with perfectly predictable and repeatable metallurgical properties.

A failure to achieve uniformity could lead to catastrophic component failure, making the reliability of a horizontal furnace a mission-critical requirement.

Understanding the Trade-offs

Choosing a furnace requires understanding its design intent relative to other options, such as a tube furnace.

Chamber vs. Tube Design

A horizontal furnace uses a large, open chamber to process multiple or bulky parts in a single batch. In contrast, a tube furnace heats a sample产品 inside a narrow cylindrical tube.

The chamber design bottleneis ideal for treating three-dimensional components, while a tube furnace is better suited for processing powders, wires, or small, uniform samples, often in a continuous or linear fashion.

Batch Processing vs. Specialized Setups

The front-loading furnace is the workhorse for batch production. You load it, run a cycle, and unload it. Other designs, like a split tube furnace, are built for a different purpose.

A split tube furnace opens lengthwise, offering rapid access to the sample. This is not for production but for research and development, where experimental setups inside the tube need to be changed frequently.

Footprint and Scale

Industrial front-loading furnaces are large, robust machines built for production environments. Laboratory tube furnaces, by comparison, are often compact, space-saving units designed for experimental work on a much smaller scale.

Making the Right Choice for Your Goal

Your application's goal dictates the correct furnace geometry.

- If your primary focus is treating multiple, high-value components with perfect consistency: The front-loading horizontal furnace is the industry standard for its unmatched thermal uniformity.

- If your primary focus is processing a continuous flow of material or a small, linear sample: A tube furnace is a more efficient and appropriate tool.

- If your primary focus is laboratory research requiring frequent access to the heated sample: The convenience of a split-tube furnace is likely your best option.

Understanding these core design principles empowers you to select the precise thermal processing tool your application demands.

Summary Table:

| Feature | Description |

|---|---|

| Cold Wall Structure | Externally cooled vessel for heat isolation and structural integrity |

| Hot Zone Options | Graphite (high temp) or metallic (clean vacuum) elements |

| Front-Loading Access | Sliding doors for easy loading/unloading of parts |

| Thermal Uniformity | Precise control for consistent material properties |

| Applications | Aerospace, defense, automotive, atomic energy for brazing, sintering |

| Design Type | Batch furnace ideal for 3D components in production environments |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior thermal processing. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does the sealing mechanism in Quartz Tube Furnaces differ from traditional systems? Discover Advanced Sealing for Reliable Results

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing