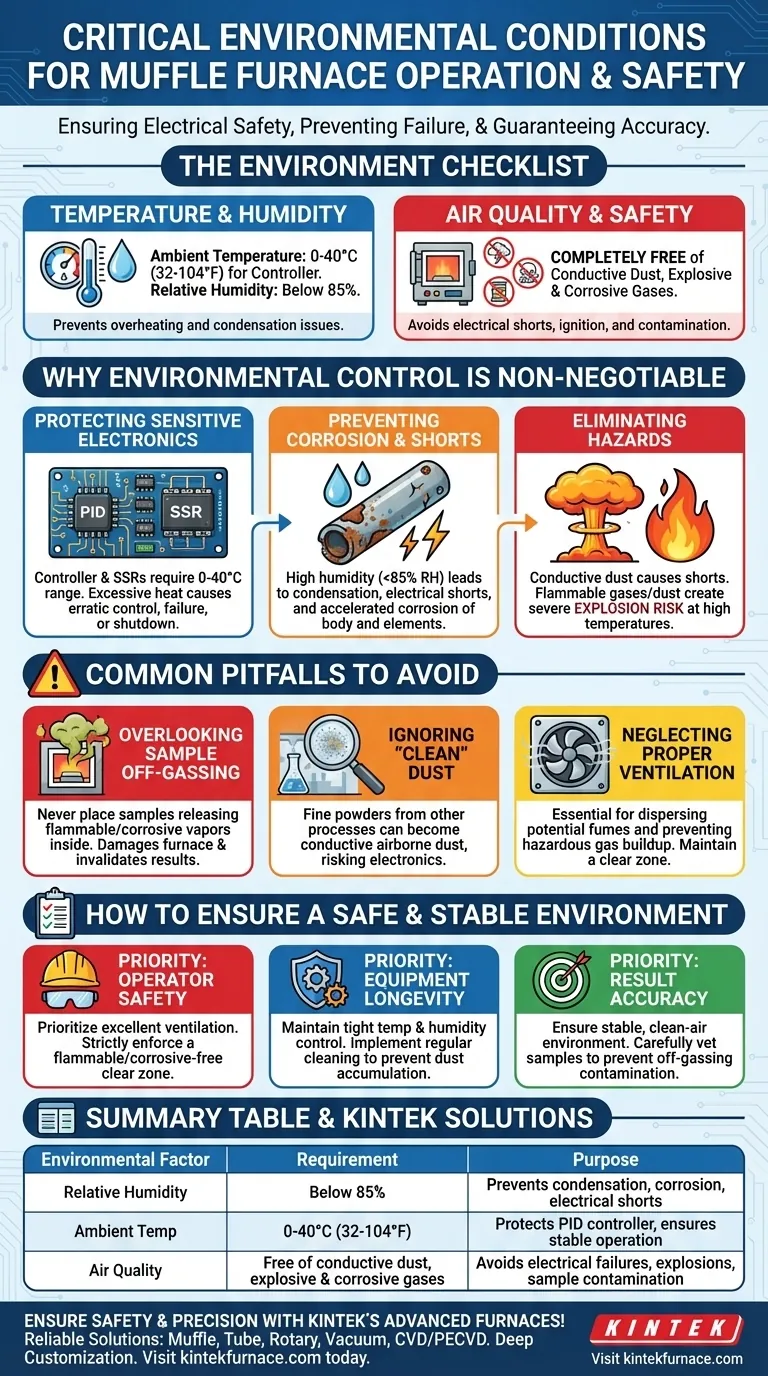

To operate safely and effectively, a muffle furnace and its controller require an environment with a relative humidity below 85% and an ambient temperature between 0-40°C for the controller. The surrounding air must be completely free of conductive dust, explosive gases, and corrosive gases to prevent equipment damage and ensure operator safety.

The specified environmental conditions for a muffle furnace are not mere recommendations; they are fundamental requirements for ensuring electrical safety, preventing catastrophic failure, and guaranteeing the accuracy and repeatability of your results.

Why Environmental Control is Non-Negotiable

A muffle furnace's performance and longevity are directly tied to the quality of its operating environment. Ignoring these parameters introduces significant risks to the equipment, the sample, and the operator.

Protecting Sensitive Electronics

The brain of the modern muffle furnace is its PID controller, often working with Solid State Relays (SSRs). These components are designed to function reliably only within a specific ambient temperature range, typically 0-40°C (32-104°F).

Operating the controller in an environment hotter than this can lead to overheating, causing erratic temperature control, premature component failure, or a complete system shutdown.

Preventing Corrosion and Electrical Shorts

The requirement for relative humidity below 85% is critical for preventing moisture-related damage. High humidity can lead to condensation on cooler electrical components, creating a risk of short circuits.

Furthermore, a damp environment accelerates the corrosion of the furnace's metal body and can degrade the heating elements over time, shortening their operational life.

Eliminating Ignition and Explosion Hazards

An atmosphere containing conductive dust, flammable materials, or explosive gases is incompatible with high-temperature equipment. Conductive dust (like fine metal or carbon powders) can settle on circuit boards and create unintended electrical pathways, causing shorts.

More critically, any flammable gas or airborne combustible dust presents a severe explosion risk when exposed to the high temperatures of the furnace, even if the source is just nearby storage.

Ensuring Process Integrity

The stability of the surrounding environment directly impacts the furnace's ability to maintain a uniform and accurate internal temperature. A stable ambient temperature allows the PID controller to work more efficiently, leading to more precise results.

Likewise, keeping the air free of corrosive gases (such as acid vapors) is essential. These gases can not only damage the furnace but can also react with the sample being processed, contaminating it and invalidating your work.

Understanding the Common Pitfalls

Adhering to the guidelines involves more than a casual check of the room. Several common oversights can lead to a hazardous or damaging operating environment.

Overlooking Sample Off-Gassing

The most immediate environment is the one you create inside the furnace. Never place samples that can release flammable, explosive, or corrosive vapors directly into the chamber.

This includes certain plastics, volatile organic compounds, and liquids. The off-gassing can create a dangerous micro-environment, damage the furnace lining and elements, and ruin your process.

Ignoring the Risk of "Clean" Dust

A laboratory may appear clean, but fine powders from other processes can become airborne. These particulates can act as conductive dust, posing a risk to the furnace's electronics.

Ensure the furnace is situated in an area with minimal air cross-contamination from grinding, mixing, or other powder-handling activities.

Neglecting Proper Ventilation

Proper ventilation is not just for removing heat from the room; it is essential for safely dispersing any potential fumes that may escape the furnace.

Inadequate ventilation allows for the potential buildup of hazardous or corrosive gases, violating the core operating requirements and endangering personnel.

How to Ensure a Safe and Stable Operating Environment

Use these guidelines to create the ideal conditions for your muffle furnace based on your primary objective.

- If your primary focus is operator safety: Prioritize excellent ventilation and strictly enforce a "clear zone" around the furnace, free of all flammable, explosive, or corrosive materials.

- If your primary focus is equipment longevity: Maintain tight control over ambient room temperature and humidity, and implement a regular cleaning schedule to prevent any dust accumulation on or around the unit.

- If your primary focus is result accuracy: Ensure a stable, clean-air environment and carefully vet all samples to prevent any off-gassing that could contaminate the process or react with the sample.

Controlling the operating environment is the foundation for safe, reliable, and accurate high-temperature work.

Summary Table:

| Environmental Factor | Requirement | Purpose |

|---|---|---|

| Relative Humidity | Below 85% | Prevents condensation, corrosion, and electrical shorts |

| Ambient Temperature | 0-40°C (32-104°F) | Protects PID controller and ensures stable operation |

| Air Quality | Free of conductive dust, explosive gases, corrosive gases | Avoids electrical failures, explosions, and sample contamination |

Ensure your lab's safety and precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability tailors equipment to your unique experimental needs, enhancing performance and longevity. Contact us today to discuss how our furnaces can meet your specific environmental requirements and boost your research outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production