Modern muffle furnaces are engineered for efficiency, not just high temperatures. Their energy-saving capabilities stem from a combination of superior materials and intelligent control systems. The key features include advanced ceramic fiber insulation to minimize heat loss, high-efficiency heating elements like silicon carbide for better power conversion, and smart controllers that dynamically adjust power output to maintain temperature without wasting energy.

The core principle behind modern furnace efficiency is not just using less power, but controlling heat with unprecedented precision. Superior heat containment and intelligent power management work together to deliver faster cycles, greater temperature stability, and lower operational costs.

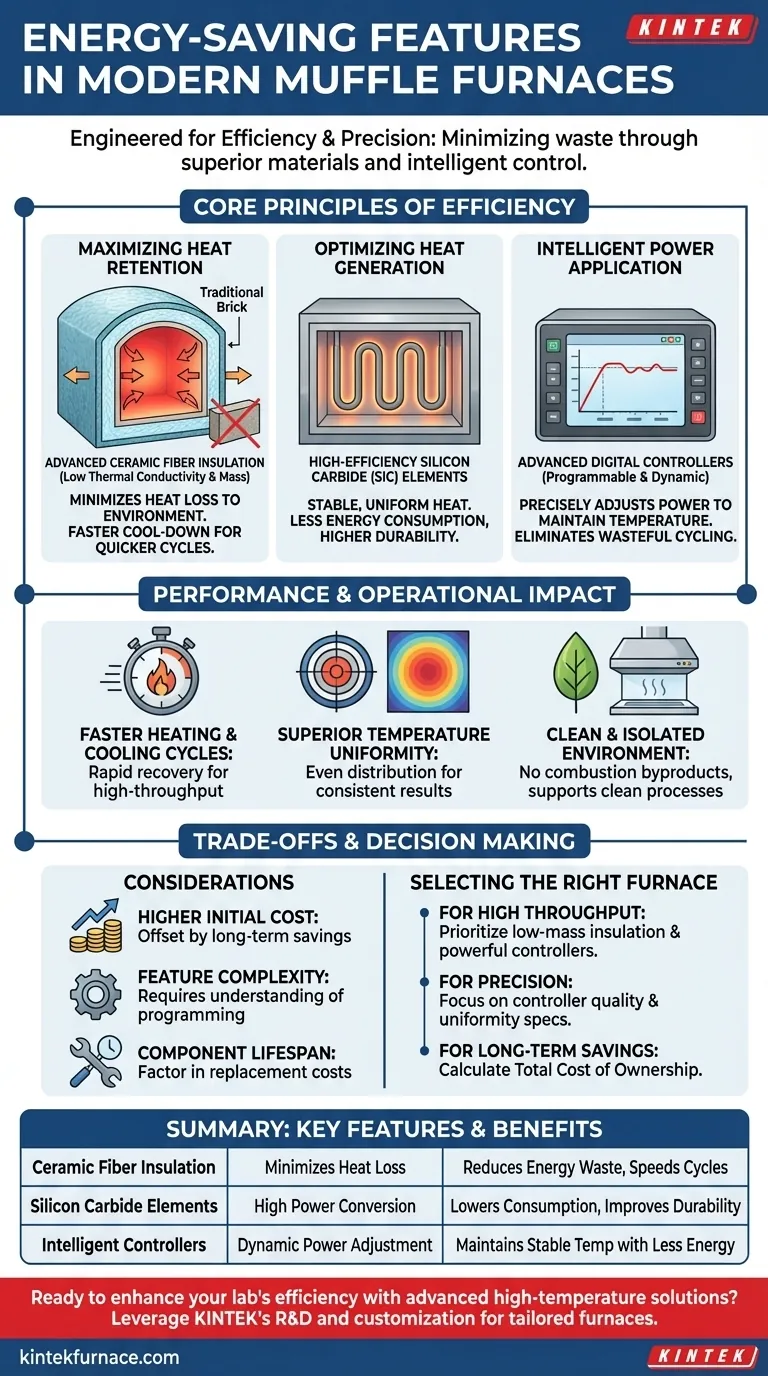

The Core Principles of Furnace Energy Efficiency

A muffle furnace's efficiency is determined by two primary factors: its ability to generate and retain heat, and its intelligence in applying that heat precisely where and when it is needed. Modern designs excel in both areas.

Principle 1: Maximizing Heat Retention

The single biggest source of energy waste in any furnace is heat loss to the surrounding environment. Modern muffle furnaces combat this with advanced insulation.

Instead of traditional, dense refractory brick, they use lightweight ceramic fiber insulation. This material has extremely low thermal conductivity, meaning it is far more effective at keeping heat inside the chamber. It also has a lower thermal mass, so it absorbs less heat itself, allowing the furnace to cool down faster and prepare for the next cycle more quickly.

Principle 2: Optimizing Heat Generation

The heating elements are the heart of the furnace, responsible for converting electricity into thermal energy. Their material and design are critical for efficiency.

Many modern furnaces utilize high-efficiency silicon carbide (SiC) heating elements. These components are capable of providing stable, uniform heat while consuming less energy than older element types. Their durability also contributes to a lower total cost of ownership over the furnace's lifespan.

Principle 3: Intelligent Power Application

Generating heat efficiently is only half the battle; applying it intelligently is what sets modern furnaces apart. This is accomplished through advanced digital control systems.

These controllers offer fully programmable heating and cooling rates. More importantly, they feature "intelligent heating" functions that automatically adjust power. Once the target temperature is reached, the system reduces power output significantly, providing just enough energy to counteract heat loss and maintain a stable, uniform temperature without the constant, wasteful cycling of older models.

How These Features Translate to Performance

Energy efficiency is not just about saving money on electricity. These modern features directly enhance the furnace's performance, reliability, and utility for critical applications.

Faster Heating and Cooling Cycles

The combination of efficient heating elements and low-mass ceramic fiber insulation allows modern furnaces to achieve rapid heating and recovery times. This speed is essential for high-throughput labs and specific processes like thermogravimetric analysis (TGA) or quenching.

Superior Temperature Uniformity

Intelligent controllers and well-engineered heating element placement ensure even heat distribution throughout the chamber. This uniformity is non-negotiable for applications like materials research, heat-treating, and ashing, where consistent results depend on every part of the sample experiencing the same temperature.

A Clean and Isolated Environment

A core function of a muffle furnace is to isolate the heated object from contaminants. The efficiency of the electric heating system supports this perfectly, as it produces no fumes or combustion byproducts, ensuring a clean process environment.

Understanding the Trade-offs

While modern features offer clear advantages, it's important to recognize the associated considerations.

Initial Cost vs. Operating Cost

Furnaces equipped with ceramic fiber insulation and advanced controllers typically have a higher upfront purchase price. This initial investment is offset by lower long-term energy bills and potentially higher throughput, but it is a key factor in the initial decision.

Feature Complexity

Fully programmable digital controllers provide immense flexibility, but they also introduce a layer of complexity. To achieve maximum efficiency, operators must understand how to properly program heating rates and utilize energy-saving modes, which may require training.

Component Lifespan and Maintenance

High-efficiency components like silicon carbide elements are highly reliable but are still consumables with a finite lifespan. Their replacement cost should be factored into the total cost of ownership analysis when comparing models.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its features to your specific goals.

- If your primary focus is high-throughput processing: Prioritize models with low thermal mass ceramic fiber insulation and powerful, programmable controllers for the fastest possible heating and cooling cycles.

- If your primary focus is process precision and repeatability: Focus on the quality of the temperature controller and the manufacturer's specifications for temperature uniformity, which are critical for materials research and analysis.

- If your primary focus is long-term cost reduction: Calculate the total cost of ownership, weighing the higher initial price of an energy-efficient model against its projected savings in electricity consumption over its lifespan.

Ultimately, understanding these energy-saving features empowers you to select a furnace that aligns not just with your budget, but with your core scientific or production goals.

Summary Table:

| Feature | Key Benefit | Impact on Efficiency |

|---|---|---|

| Ceramic Fiber Insulation | Minimizes heat loss | Reduces energy waste and speeds up cycles |

| Silicon Carbide Heating Elements | High power conversion | Lowers energy consumption and improves durability |

| Intelligent Digital Controllers | Dynamic power adjustment | Maintains stable temperature with less energy |

Ready to enhance your lab's efficiency with advanced high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for energy savings and superior performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites