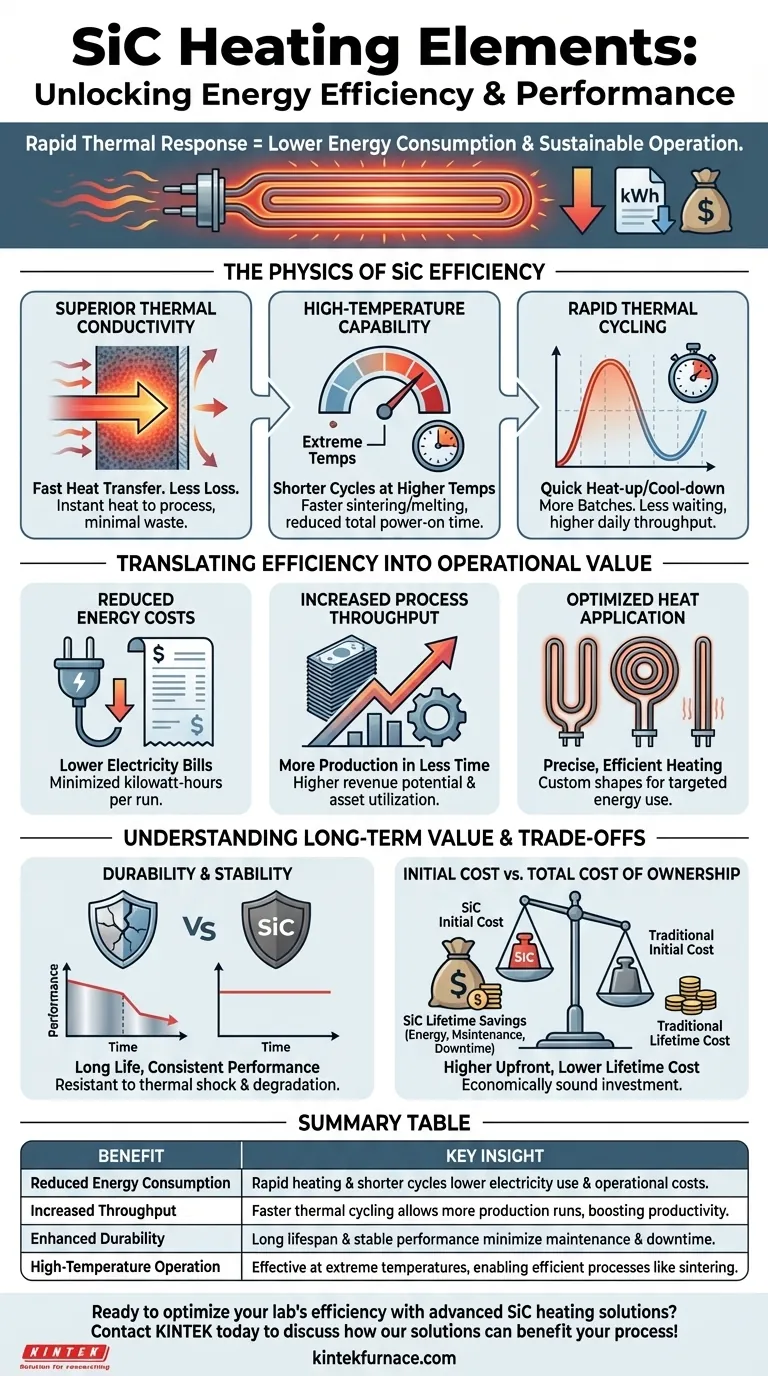

At their core, the energy efficiency benefits of Silicon Carbide (SiC) heating elements stem from their ability to reach very high temperatures extremely quickly. This rapid thermal response shortens process cycle times, directly reducing the total energy consumed per operation. This fundamental characteristic leads to lower operational costs and a more sustainable industrial heating process.

The true value of SiC heating elements is not just a reduction in energy bills, but a powerful combination of speed, durability, and high-temperature performance. This translates to higher throughput and a lower total cost of ownership compared to many traditional heating technologies.

The Physics of SiC Efficiency

To understand the operational benefits of SiC, we must first look at its underlying material properties. The efficiency is not a single feature but the result of several interconnected physical characteristics.

Superior Thermal Conductivity

Silicon Carbide possesses excellent thermal conductivity. This means it transfers heat energy from its core to its surface—and into your process—with exceptional speed and minimal loss.

Think of it like the difference between heating a thick ceramic pot and a thin copper pan. The copper pan (SiC) gets hot almost instantly and transfers that heat to its contents efficiently, while the ceramic pot (less conductive materials) takes longer and wastes more energy just heating itself.

High-Temperature Capability

SiC elements can operate effectively at very high temperatures, often far exceeding the limits of traditional metallic elements.

Running a process at a higher temperature can dramatically shorten the required time for tasks like sintering, melting, or drying. Less time with the heating system powered on means a direct and significant reduction in overall energy consumption.

Rapid Thermal Cycling

The combination of high thermal conductivity and low thermal expansion allows SiC elements to heat up and cool down very quickly without risk of thermal shock or breakage.

For batch-based industrial processes, this is a critical efficiency driver. Less time spent waiting for a furnace to reach temperature or cool down means more cycles can be completed per day, directly boosting productivity and throughput.

Translating Efficiency into Operational Value

These physical properties deliver tangible benefits that impact an operation's bottom line and overall performance.

Reduced Energy Consumption & Costs

The most direct benefit is a lower electricity bill. By heating faster and enabling shorter process times, SiC elements minimize the kilowatt-hours required for each production run.

Increased Process Throughput

For many businesses, time is more valuable than energy. By significantly reducing cycle times, SiC heaters allow you to produce more goods in the same amount of time, increasing revenue potential and asset utilization.

Optimized Heat Application

SiC elements can be manufactured in a wide variety of custom shapes and sizes. This allows for the design of heating systems that apply energy precisely where it is needed, minimizing wasted heat and further improving overall system efficiency.

Understanding the Trade-offs and Long-Term Value

While SiC offers compelling advantages, a complete technical assessment requires understanding its long-term performance and initial investment.

The Impact of Durability and Lifespan

SiC is a mechanically strong ceramic with a low coefficient of thermal expansion. This makes it highly resistant to breakage during rapid temperature changes and ensures a long, reliable service life.

This durability reduces costs associated with frequent element replacement, maintenance labor, and, most importantly, unplanned production downtime.

Performance Stability Over Time

Unlike some metallic heating elements that can degrade and require more power to hold the same temperature as they age, SiC elements provide very stable and consistent performance throughout their lifespan. This ensures your process remains predictable and your energy consumption does not creep upward over time.

Initial Cost vs. Total Cost of Ownership

SiC heating elements typically have a higher initial purchase price than traditional metallic elements. However, this upfront cost must be weighed against the total cost of ownership.

When factoring in lower energy bills, reduced maintenance, minimal downtime, and higher throughput, the lifetime value of SiC often makes it the more economically sound investment.

Making the Right Choice for Your Process

Selecting the right heating element technology requires aligning its capabilities with your primary operational goals.

- If your primary focus is minimizing direct operating costs: SiC is a premier choice due to its direct impact on energy consumption and reduced need for maintenance and replacement.

- If your primary focus is maximizing throughput and productivity: The rapid thermal cycling capability of SiC is its most powerful advantage, enabling more production cycles per shift.

- If your primary focus is process consistency and reliability: The exceptional durability and stable performance of SiC ensure your heating process is repeatable and dependable over the long term.

Ultimately, choosing SiC is a strategic investment in a more efficient, productive, and reliable thermal process.

Summary Table:

| Benefit | Key Insight |

|---|---|

| Reduced Energy Consumption | Rapid heating and shorter cycles lower electricity use and operational costs. |

| Increased Throughput | Faster thermal cycling allows more production runs, boosting productivity. |

| Enhanced Durability | Long lifespan and stable performance minimize maintenance and downtime. |

| High-Temperature Operation | Effective at extreme temperatures, enabling efficient processes like sintering. |

Ready to optimize your lab's efficiency with advanced SiC heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs, delivering energy savings, higher throughput, and reliable performance. Contact us today to discuss how our solutions can benefit your process!

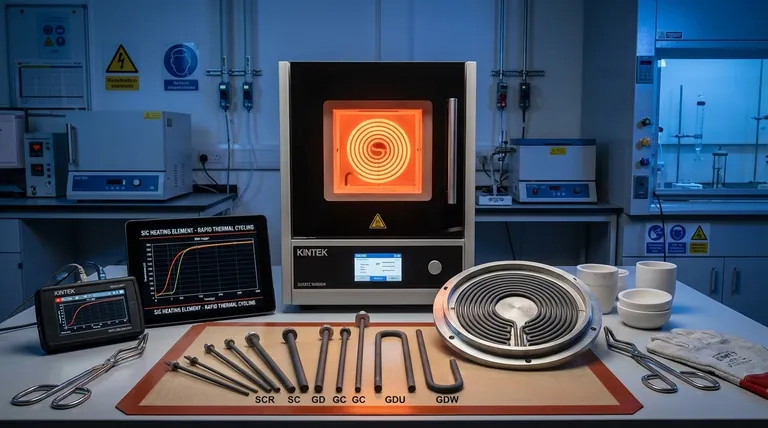

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism