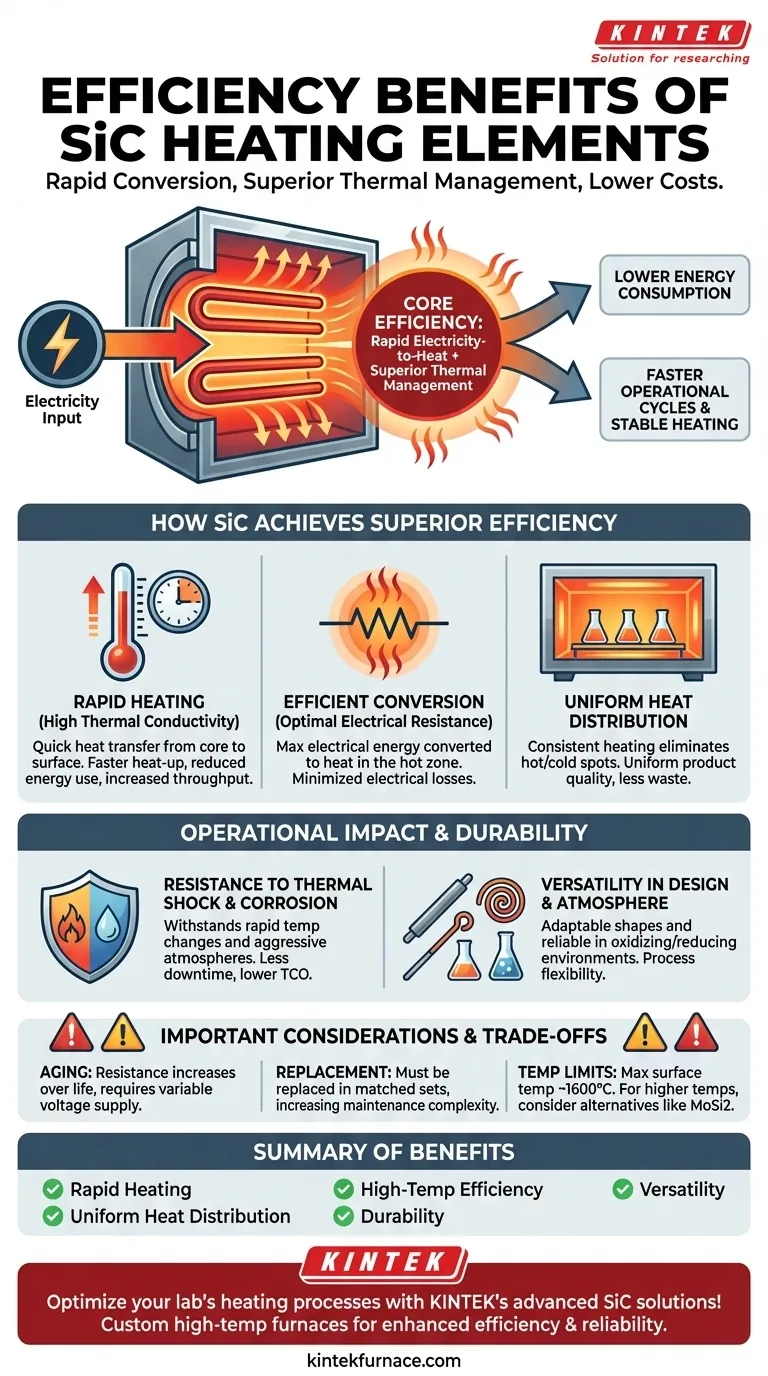

At its core, the efficiency of Silicon Carbide (SiC) heating elements stems from two primary characteristics: their ability to rapidly convert electricity into usable heat and their superior thermal management. This combination results in lower energy consumption, faster operational cycles, and a more stable heating environment, directly impacting both operational costs and product quality.

True efficiency in high-temperature processes is not just about reducing energy bills. It's about achieving consistent, rapid, and reliable heat delivery, which minimizes waste in time, materials, and energy. SiC excels by optimizing the entire thermal process, not just the power input.

How SiC Achieves Superior Efficiency

The performance benefits of SiC are rooted in its fundamental material properties. These properties directly translate into a more efficient heating process compared to traditional metallic or other ceramic elements in many applications.

High Thermal Conductivity for Rapid Heating

SiC elements possess excellent thermal conductivity. This allows them to transfer heat quickly and evenly from the element's core to its surface and into the furnace chamber.

This rapid heat transfer means your furnace reaches its target temperature faster. Less time spent on heat-up translates directly to reduced energy consumption and increased production throughput per cycle.

Optimal Electrical Resistance at High Temperatures

Unlike many materials, SiC's electrical resistance profile is optimized for high-temperature heating. It becomes highly resistive at its operating temperature, a key factor in its efficiency.

This characteristic ensures that the maximum amount of electrical energy is converted into thermal energy precisely when and where it's needed most—inside the hot zone of the furnace. This efficient energy conversion minimizes electrical losses.

Uniform Heat Distribution

The material properties and typical rod or spiral shapes of SiC elements promote exceptionally uniform heat distribution. This creates a stable thermal environment without significant hot or cold spots.

Consistent heating ensures uniform product quality, reducing defects and scrap. It also prevents the control system from over-firing certain zones to compensate for others, which wastes significant energy.

The Operational Impact of SiC Properties

Efficiency isn't just about energy; it's also about uptime, reliability, and process flexibility. The robust nature of SiC delivers key operational advantages that contribute to a lower total cost of ownership.

Resistance to Thermal Shock and Corrosion

SiC is highly resistant to thermal shock, meaning it can withstand rapid temperature changes without cracking or failing. It also maintains its integrity in chemically aggressive or oxidizing atmospheres.

This durability leads to less frequent element replacement and reduced furnace downtime, which is a critical component of overall operational efficiency.

Versatility in Design and Atmosphere

SiC elements can be manufactured in a wide variety of shapes and sizes, allowing for optimized furnace designs tailored to specific processes like metal treatment, glass firing, or semiconductor manufacturing.

Furthermore, they perform reliably in both oxidizing and reducing atmospheres, offering a level of process flexibility that is not possible with many alternative heating elements.

Understanding the Trade-offs and Limitations

While highly efficient, SiC elements are not the universal solution for every heating application. Understanding their operational characteristics and limitations is critical for making an informed decision.

Aging and Resistance Change

Over their operational life, SiC elements "age," and their electrical resistance gradually increases. This change must be managed to maintain consistent power output and efficiency.

This often requires a power supply system with a variable voltage output (typically using SCRs or tapped transformers) to compensate for the resistance change over time.

Replacement Strategy

When an SiC element fails, it cannot simply be replaced with a single new one. Due to the resistance changes from aging, a new element would have a significantly different resistance from the older ones in the circuit.

To maintain a balanced electrical load and uniform heating, elements must be replaced in matched sets or groups. This increases the immediate cost and complexity of maintenance.

Temperature and Lifespan Limits

SiC elements generally have a maximum surface temperature of around 1600°C, which translates to a maximum furnace chamber temperature of approximately 1530-1540°C.

For applications requiring temperatures above this, or for those prioritizing the longest possible element lifespan above all else, other materials like Molybdenum Disilicide (MoSi2) may be a more suitable choice.

Making the Right Choice for Your Application

Selecting the right heating element requires balancing performance, cost, and operational requirements.

- If your primary focus is rapid process cycling: SiC is an excellent choice due to its ability to heat up and cool down quickly, maximizing throughput.

- If your primary focus is versatility across different atmospheres: SiC's robust performance in both oxidizing and reducing environments makes it a highly flexible and reliable option.

- If your primary focus is maximizing temperature above 1550°C: You should evaluate alternatives like MoSi2, which are designed for higher temperature ranges.

Ultimately, choosing SiC is a decision to invest in process speed and thermal stability, understanding the specific maintenance requirements needed to sustain its high efficiency.

Summary Table:

| Benefit | Description |

|---|---|

| Rapid Heating | High thermal conductivity enables quick temperature rise, cutting energy use and cycle times. |

| Uniform Heat Distribution | Eliminates hot/cold spots for consistent product quality and less energy waste. |

| High-Temperature Efficiency | Optimal electrical resistance at high temps ensures maximum energy conversion to heat. |

| Durability | Resistant to thermal shock and corrosion, reducing downtime and replacement frequency. |

| Versatility | Works in various atmospheres and designs, adaptable to multiple industrial processes. |

Optimize your lab's heating processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced efficiency and reliability. Contact us today to discuss how our tailored solutions can benefit your operations!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan