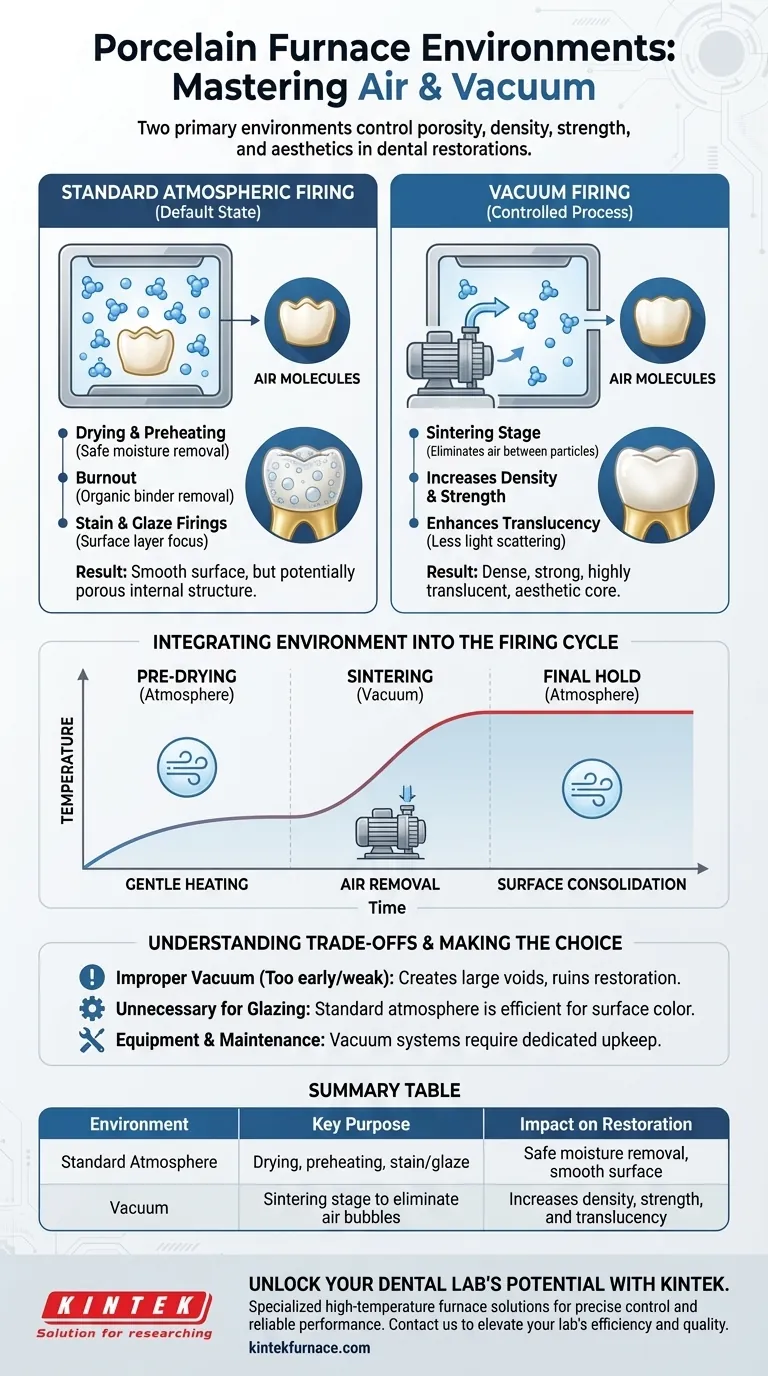

Porcelain furnaces operate within two primary environments: a standard air atmosphere or a controlled vacuum. The choice is a critical process parameter, not an equipment feature, and is deliberately programmed into a firing cycle to directly influence the final density, strength, and aesthetic quality of a dental restoration.

The decision to fire porcelain under a vacuum versus a standard atmosphere is fundamentally about controlling porosity. A vacuum environment is used during specific stages of the firing cycle to remove trapped air, resulting in a denser, stronger, and more aesthetically pleasing final ceramic.

The Role of the Firing Environment

The environment inside the furnace muffle directly impacts how individual porcelain particles fuse together, a process known as sintering. The presence or absence of air at specific temperatures determines the internal structure of the finished crown or bridge.

Standard Atmospheric Firing

In a standard atmospheric environment, the furnace chamber contains normal air. This is the default state and is essential for specific stages of the firing process.

Atmospheric pressure is used during the initial drying and preheating phases. It allows for the gentle removal of water and the safe burnout of any organic binding agents within the porcelain paste.

It is also the environment used for final stain and glaze firings, where the goal is to develop a smooth, glass-like surface layer without altering the already-sintered substructure.

Vacuum Firing

A vacuum environment is created when a pump removes most of the air from the furnace chamber. This is not used for the entire cycle but is a crucial step for building the core body of a restoration.

The primary purpose of the vacuum is to eliminate porosity. By removing air from between the porcelain particles as they begin to fuse, it prevents tiny air bubbles from becoming trapped within the final material.

How a Vacuum Improves Ceramic Quality

Removing these voids has two major benefits. First, it creates a denser and stronger material, significantly improving the restoration's ability to withstand the forces of mastication.

Second, it enhances the optical properties and aesthetics of the porcelain. Trapped air bubbles scatter light, creating a cloudy or opaque appearance. A dense, void-free ceramic has superior translucency, allowing it to mimic the appearance of a natural tooth more effectively.

Integrating Environment into the Firing Cycle

A furnace doesn't just operate in one environment. The pressure is changed at precise moments as part of a larger, programmable firing schedule that also controls time and temperature.

The Pre-Drying Stage (Atmosphere)

Every cycle begins at atmospheric pressure. The temperature slowly rises to dry the porcelain, ensuring no moisture is trapped, which could turn to steam and damage the restoration.

The Sintering Stage (Vacuum)

As the temperature climbs towards the sintering point, the vacuum pump engages. This is the critical phase where the vacuum removes air while the porcelain particles are fusing, ensuring high density in the dentine and enamel layers.

The Final Hold (Atmosphere)

Just before or at the peak firing temperature, the vacuum is released. This return to atmospheric pressure helps consolidate the outer surface of the restoration, creating a natural, semi-glossy sheen directly out of the furnace.

Understanding the Trade-offs

While a vacuum is critical for quality, its application must be precise. Mismanagement of the furnace environment can create problems rather than solve them.

Porosity from an Improper Vacuum

If a vacuum is pulled too early while moisture is still present, it can cause the water to boil, creating large voids and ruining the restoration. Likewise, a weak or leaky vacuum system will fail to remove enough air, leading to unwanted porosity.

Unnecessary for Certain Applications

A vacuum is generally not required for simple stain and glaze cycles. The goal of these low-temperature firings is to fuse a thin surface layer, and a vacuum provides no significant benefit and may even alter the desired surface texture of certain stains.

Equipment and Maintenance Demands

Furnaces equipped with a vacuum system require more maintenance. The vacuum pump and the chamber's seals must be kept in perfect working order to ensure a consistent and effective vacuum level on every run.

Making the Right Choice for Your Goal

The correct use of the furnace environment is dictated by the specific step in the restoration fabrication process.

- If your primary focus is building a strong crown or bridge: Utilizing a properly programmed vacuum cycle during the dentine and enamel firing stages is essential for achieving optimal density and strength.

- If your primary focus is applying final surface color and glaze: Firing in a standard atmosphere is the correct and most efficient procedure for these low-temperature aesthetic cycles.

- If your primary focus is achieving a "natural glaze" without polishing: Mastering the precise temperature for releasing the vacuum is key to creating a smooth, consolidated surface directly from the firing cycle.

Ultimately, mastering the interplay between atmosphere and vacuum is fundamental to transforming porcelain powder into a durable and lifelike dental restoration.

Summary Table:

| Environment | Key Purpose | Impact on Restoration |

|---|---|---|

| Standard Atmosphere | Drying, preheating, stain/glaze firings | Safe removal of moisture, develops smooth surface |

| Vacuum | Sintering stage to eliminate air bubbles | Increases density, strength, and translucency |

Unlock the Full Potential of Your Dental Lab with KINTEK

Are you striving for flawless, high-strength dental restorations with superior aesthetics? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—enhanced by deep customization to meet your unique experimental needs. Whether you're optimizing vacuum cycles for dense ceramics or refining atmospheric firings, our expertise ensures precise control and reliable performance. Don't let equipment limitations hold you back—contact us today to discuss how KINTEK can elevate your lab's efficiency and restoration quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique