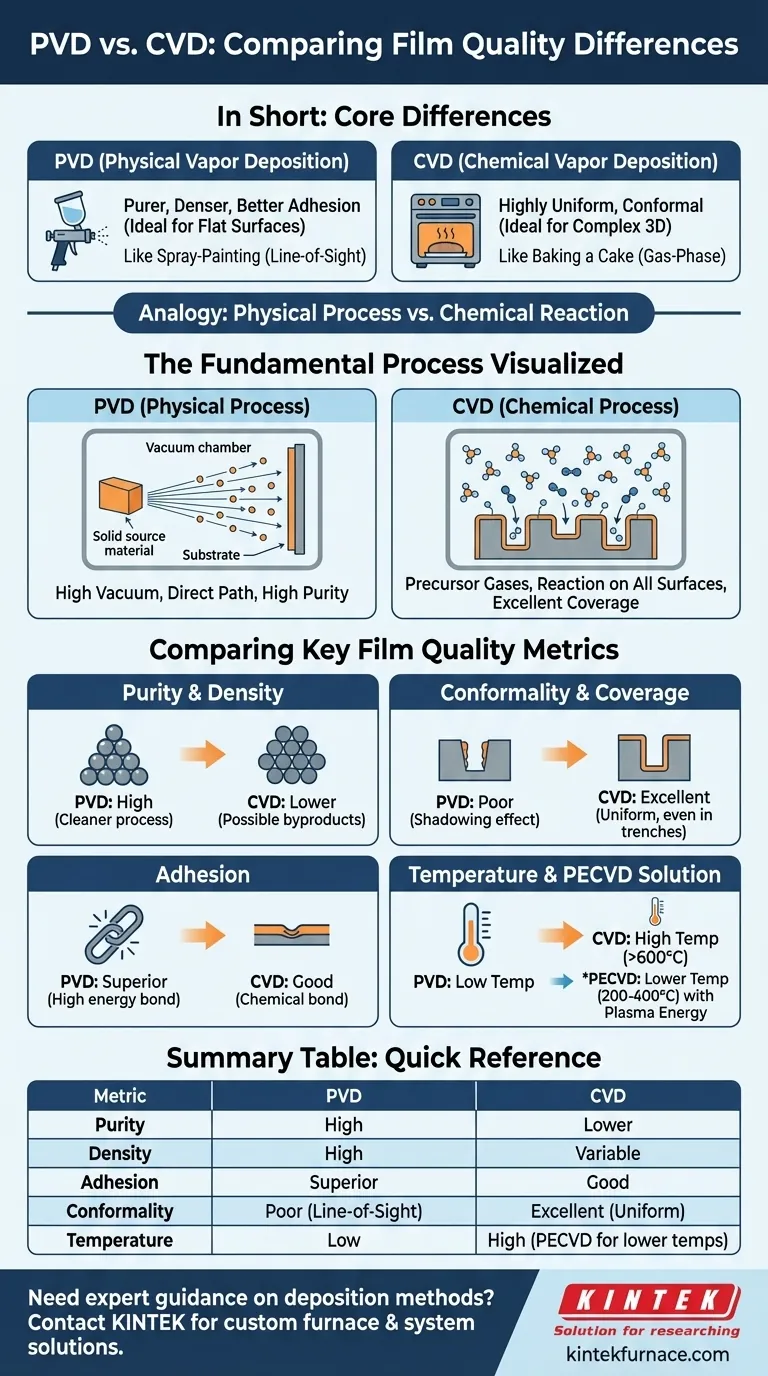

In short, PVD typically produces purer, denser films with better adhesion, while CVD excels at creating highly uniform (conformal) coatings over complex, non-flat surfaces. Neither method is universally superior; the "better" quality depends entirely on the specific requirements of your application, primarily the geometry of the part and the desired film properties.

The core difference comes down to the process itself: PVD is a physical, line-of-sight process akin to spray-painting, resulting in high purity. CVD is a chemical, gas-phase process like baking a cake, resulting in excellent coverage everywhere. Understanding this distinction is the key to choosing the right method.

The Fundamental Process: Physical vs. Chemical

The differences in film quality are not arbitrary; they are a direct consequence of how each deposition method works at a molecular level.

PVD: A "Line-of-Sight" Physical Process

Physical Vapor Deposition (PVD) operates in a high vacuum. A solid source material is vaporized (e.g., by sputtering or evaporation), and these atoms or molecules travel in a straight line to condense onto the substrate.

This physical, non-reactive process is why PVD excels at creating exceptionally pure films. There are very few other gas molecules in the chamber to get trapped in the growing film.

CVD: A Gas-Phase Chemical Reaction

Chemical Vapor Deposition (CVD) involves introducing precursor gases into a reaction chamber. These gases react on the hot surface of the substrate, forming the desired solid film and volatile byproducts that are then pumped away.

Because it relies on a gas that fills the entire chamber, CVD can coat all surfaces of a complex part with a highly uniform thickness.

Comparing Key Film Quality Metrics

Each process creates films with a distinct profile of strengths and weaknesses.

Purity and Density

PVD generally produces purer and denser films. The high-vacuum environment minimizes the chance of contaminants or byproduct gases being incorporated into the film, leading to higher material purity.

CVD films can have lower purity because precursor chemicals may not fully react, or chemical byproducts can become trapped in the film structure.

Conformality and Coverage

CVD is the undisputed leader in conformality. The precursor gases can diffuse into and react within intricate features, trenches, and internal surfaces, creating a film of even thickness everywhere.

PVD is a line-of-sight process and struggles with complex geometries. Surfaces not directly facing the source material will receive little to no coating, creating a "shadowing" effect.

Adhesion

PVD often yields superior adhesion. The depositing atoms in many PVD processes (like sputtering) arrive at the substrate with high kinetic energy, which helps them form a strong, intermixed bond with the surface.

While CVD adhesion is generally good, it relies on the chemical bond formed at the surface, which can sometimes be less robust than the energetic implantation of PVD.

Understanding the Trade-offs

The choice is rarely about a single quality metric but a balance of process constraints and desired outcomes.

The Temperature Dilemma

Traditional CVD requires very high temperatures (often >600°C) to drive the necessary chemical reactions. This can induce thermal stress, cause lattice mismatch, and damage temperature-sensitive substrates like polymers or certain electronic components.

PVD processes typically run at much lower temperatures, making them suitable for a wider range of substrate materials.

The Solution: Plasma-Enhanced CVD (PECVD)

To overcome the temperature limitations of CVD, Plasma-Enhanced CVD (PECVD) was developed. It uses an electric field to create plasma, an ionized gas.

This plasma provides the energy to drive the chemical reactions at much lower temperatures (typically 200-400°C). PECVD produces films with good conformality and fewer pinholes while reducing thermal stress, making it ideal for electronics and heat-sensitive applications.

Process Complexity and Safety

PVD is a conceptually simpler physical process with fewer chemical hazards. Its primary variables are deposition rate, time, and substrate temperature.

CVD is a more complex chemical process requiring precise control over gas flows, concentrations, chamber pressure, and temperature. It often involves volatile and sometimes hazardous precursor chemicals.

Making the Right Choice for Your Goal

Select the technology whose strengths align with your non-negotiable requirements.

- If your primary focus is ultimate purity on a relatively flat surface: PVD is the superior choice for its clean, dense, and highly adhesive films, ideal for optics and electronics.

- If your primary focus is uniform coating on a complex 3D part: CVD's exceptional conformality is necessary to ensure complete and even coverage on all surfaces.

- If your primary focus is conformal coating on a temperature-sensitive substrate: PECVD is the optimal solution, combining the coverage benefits of CVD with the low-temperature advantage of PVD.

Ultimately, choosing between these powerful technologies begins with a clear understanding of your application's unique geometric and material demands.

Summary Table:

| Metric | PVD | CVD |

|---|---|---|

| Purity | High | Lower |

| Density | High | Variable |

| Adhesion | Superior | Good |

| Conformality | Poor (line-of-sight) | Excellent (uniform coverage) |

| Temperature | Low | High (PECVD for lower temps) |

Need expert guidance on selecting the right deposition method for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements precisely. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What advantages do MPCVD diamond tools offer in industrial applications? Maximize Lifespan & Efficiency

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- What is Microwave Plasma Chemical Vapor Deposition (MPCVD)? Unlock Ultra-Pure Diamond Synthesis