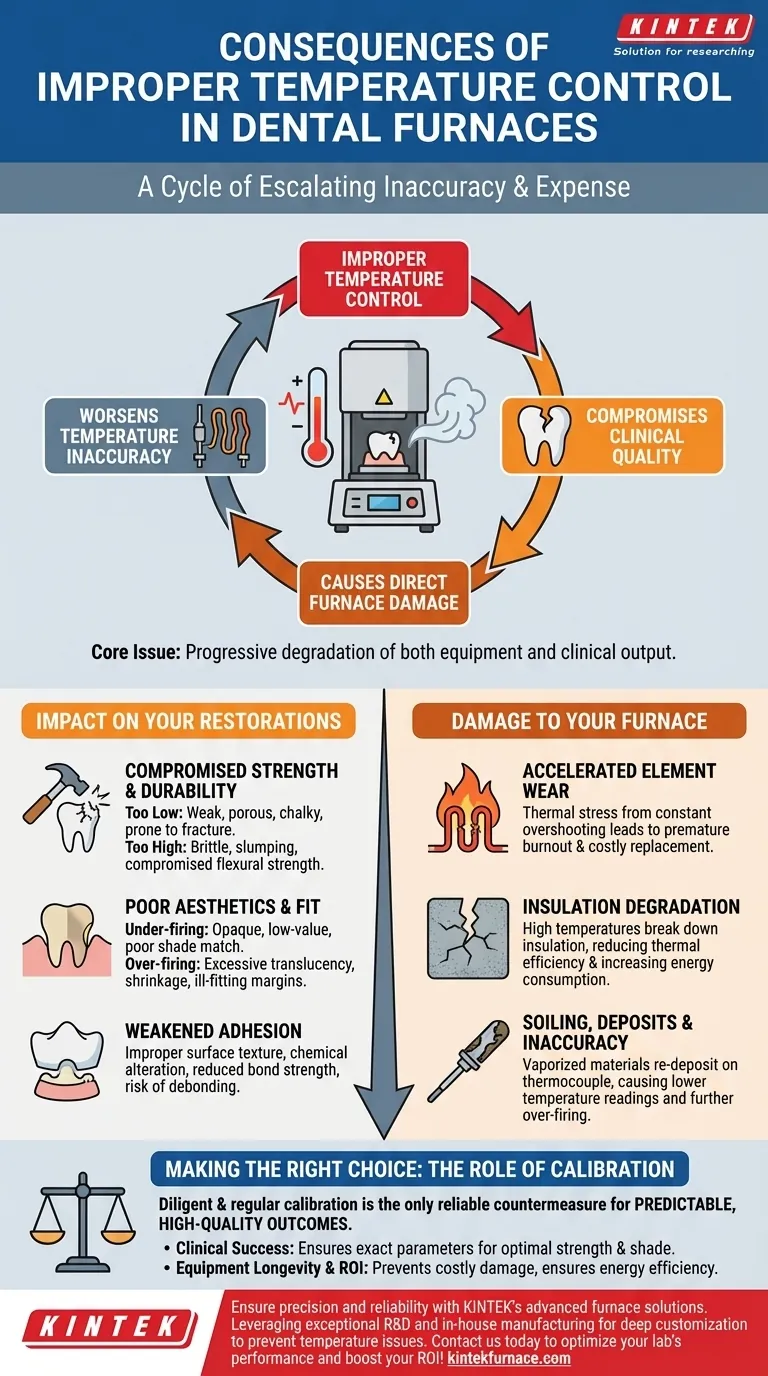

In short, improper temperature control in a dental furnace has two primary consequences: it compromises the clinical quality of your dental restorations and it causes direct physical damage to the furnace itself. These two issues create a cycle of escalating inaccuracy and expense, where poor results lead to equipment wear, which in turn guarantees even worse results.

The core issue is that inaccurate temperature is not a single failure event. It is a progressive problem that degrades both your equipment and your clinical output, making consistent, high-quality results impossible without intervention.

The Impact on Your Restorations

The final dental restoration is a direct product of the firing cycle. When the temperature is incorrect—even by a few degrees—it fundamentally alters the material properties of the ceramic, leading to clinical and aesthetic failures.

Compromised Strength and Durability

If the furnace temperature is too low, the ceramic material (like zirconia or lithium disilicate) will not fully sinter or crystallize. This results in a weak, porous, or chalky restoration that is prone to fracture under normal occlusal forces.

Conversely, if the temperature is too high, the material can "slump" or become overly glassy. This alters its internal structure, making it brittle and compromising its intended flexural strength.

Poor Aesthetics and Fit

Correct shade and translucency are entirely dependent on achieving the precise target temperature. Under-firing often results in an opaque, low-value appearance that fails to match the patient's natural dentition.

Over-firing can cause the ceramic to become too translucent and can also lead to excessive shrinkage. This shrinkage affects the final fit of the crown or veneer, potentially creating open margins that invite bacterial leakage and secondary caries.

Weakened Adhesion

The surface texture of the final restoration is critical for creating a strong mechanical and chemical bond with dental cements. An improperly fired surface can be too smooth or have a chemically altered composition, which significantly reduces bond strength and increases the risk of the restoration debonding in the patient's mouth.

The Damage to Your Furnace

Beyond the restoration itself, incorrect temperatures inflict measurable and costly damage on the furnace. This damage often creates a feedback loop that worsens the temperature inaccuracy over time.

Accelerated Wear on Heating Elements

Heating elements (the muffle) are designed to operate within a specific temperature range. Constant overshooting or struggling to reach temperature puts immense thermal stress on these components. This stress directly leads to premature burnout and failure, requiring expensive and time-consuming replacement.

Insulation Degradation

The insulation within the furnace chamber is vital for maintaining thermal efficiency. When subjected to temperatures beyond its rating, this insulation breaks down, becomes brittle, and loses its effectiveness. The furnace must then work harder and consume more energy to reach and hold its target, further stressing the heating elements.

Soiling, Deposits, and Inaccuracy

During a firing cycle, some materials can vaporize and then re-deposit on cooler surfaces inside the chamber. This includes the thermocouple, which is the sensor that reads the temperature.

A layer of deposit on the thermocouple insulates it, causing it to report a temperature that is lower than the actual chamber temperature. The furnace controller then pushes more power to the heating elements to compensate, causing the furnace to run too hot and creating a vicious cycle of further over-firing and component wear.

Making the Right Choice: The Role of Calibration

The consequences of poor temperature control are not theoretical; they are tangible failures that result in lost time, wasted materials, and dissatisfied clients. The only reliable countermeasure is diligent and regular calibration.

- If your primary focus is clinical success and aesthetic perfection: Regular calibration is the only way to ensure your furnace is achieving the exact parameters required by the ceramic manufacturer for optimal strength and shade.

- If your primary focus is equipment longevity and ROI: Proactive calibration stops the cycle of wear before it starts, preventing costly damage to heating elements and insulation while ensuring energy efficiency.

Ultimately, precise temperature control is the foundation of modern dental lab work; mastering it is essential for predictable, high-quality outcomes.

Summary Table:

| Consequence Type | Key Impacts |

|---|---|

| Restoration Quality | Compromised strength, poor aesthetics, weakened adhesion, and ill-fitting restorations |

| Furnace Damage | Accelerated wear on heating elements, insulation degradation, and sensor inaccuracies |

| Overall Effects | Increased costs, reduced ROI, and inconsistent clinical results |

Ensure precision and reliability in your dental lab with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities allow us to tailor solutions to your unique needs, preventing temperature control issues and enhancing restoration quality and equipment longevity. Contact us today to discuss how we can optimize your lab's performance and boost your ROI!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations