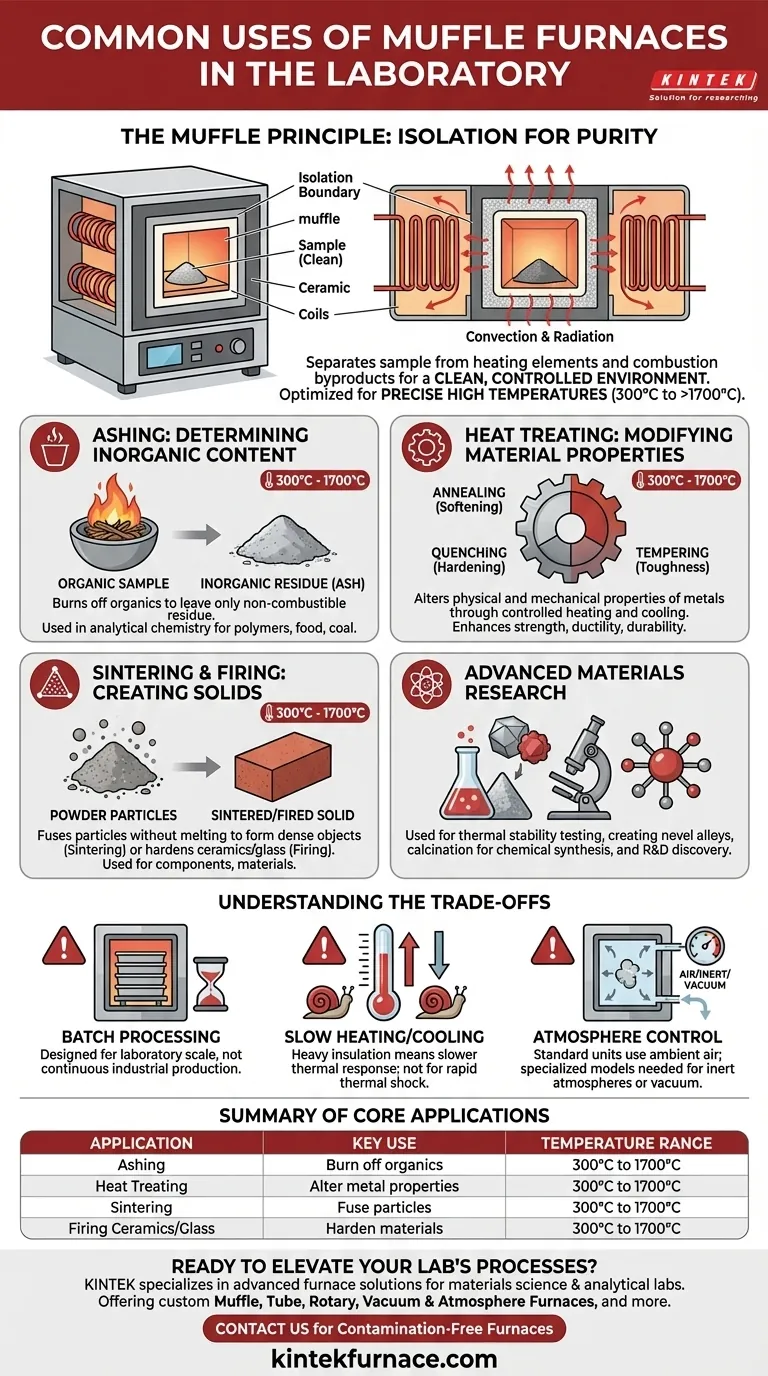

In a laboratory setting, a muffle furnace is most commonly used for high-temperature processes that require a clean, controlled environment free from combustion byproducts. The primary applications are ashing materials to determine their inorganic content, heat-treating metals to alter their properties, and firing ceramics or glass to create finished solids.

A muffle furnace is fundamentally a tool for achieving high-purity thermal processing. Its key feature—an isolated "muffle" chamber—separates the sample from the heating elements, making it essential for any high-temperature application where contamination would compromise the results.

What Makes a Muffle Furnace Unique?

While many devices can generate heat, a muffle furnace is distinguished by its design, which is optimized for precise and clean heating at high temperatures, typically from 300°C to over 1700°C.

The "Muffle" Principle: Isolation from Contamination

The defining component is the "muffle," an insulated chamber that houses the sample. In modern electric furnaces, this chamber separates the material from the heating elements.

This design prevents any byproducts of combustion or element degradation from contaminating the sample, ensuring the integrity of the process. It heats the sample primarily through convection and radiation.

Precision Temperature Control

Muffle furnaces provide highly uniform and stable temperatures. This is critical for scientific research and material testing, where repeatable and accurate conditions are necessary to obtain reliable data.

Core Applications in Detail

The combination of high heat and a clean environment makes the muffle furnace indispensable for several key laboratory tasks.

Ashing: Determining Inorganic Content

Ashing is the process of burning off all organic substances in a sample to leave behind only the inorganic, non-combustible residue (ash).

This is a fundamental technique in analytical chemistry used to determine the proportion of non-volatile content in materials like coal, polymers, or food.

Heat Treating: Modifying Material Properties

Heat treatment involves heating and cooling materials, primarily metals, to alter their physical and mechanical properties.

Processes like annealing (softening), quenching (hardening), and tempering (reducing brittleness) are performed in muffle furnaces to improve a material's strength, ductility, or durability for materials science research.

Sintering and Firing: Creating Solids

Sintering uses heat to fuse particles of metal or ceramic powder together without melting them, forming a solid, dense object. This is a core process in powder metallurgy and creating certain electronic components.

Similarly, the furnace is used for firing ceramics and glass, where controlled high temperatures harden the material and set its final form and structure.

Advanced Materials Research

Beyond these common uses, muffle furnaces are workhorses in research and development. They are used to test the thermal stability of new materials, create novel alloys, and perform calcination (thermal decomposition) for chemical synthesis.

Understanding the Trade-offs

While powerful, a muffle furnace is not the right tool for every thermal task. Understanding its limitations is key to using it effectively.

Designed for Batch Processing

Muffle furnaces are designed for processing materials in batches. Their size is typically limited to a laboratory scale, making them unsuitable for continuous or high-volume industrial production.

Heating and Cooling Rates

The heavy insulation required to reach and maintain high temperatures means that furnaces often heat up and cool down relatively slowly. Processes requiring extremely rapid temperature changes, or "thermal shock," may require specialized equipment.

Atmosphere Control as a Key Variable

A standard muffle furnace operates with the ambient air in the chamber. For processes that require an inert atmosphere (like nitrogen or argon) or a vacuum to prevent oxidation, a more advanced and costly furnace with gas ports and sealing capabilities is necessary.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align the furnace's capability with your specific objective.

- If your primary focus is quantitative analysis: Your main application will be ashing to precisely measure the inorganic composition of your samples.

- If your primary focus is materials science: You will rely on heat treatment (annealing, tempering) and sintering to modify and study the properties of metals, alloys, and ceramics.

- If your primary focus is creating new components: The key process is firing or sintering to solidify and finish your ceramic, glass, or powdered metal parts.

By understanding these core functions, you can leverage the muffle furnace as a precise and reliable tool for material analysis, transformation, and discovery.

Summary Table:

| Application | Key Use | Temperature Range |

|---|---|---|

| Ashing | Burn off organics to measure inorganic content | 300°C to 1700°C |

| Heat Treating | Alter metal properties via annealing, quenching | 300°C to 1700°C |

| Sintering | Fuse particles to form solids without melting | 300°C to 1700°C |

| Firing Ceramics/Glass | Harden materials to set final structure | 300°C to 1700°C |

Ready to elevate your lab's high-temperature processes? KINTEK specializes in advanced furnace solutions tailored for materials science and analytical labs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique experimental needs. Contact us today to discuss how our reliable, contamination-free furnaces can enhance your research and development outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis