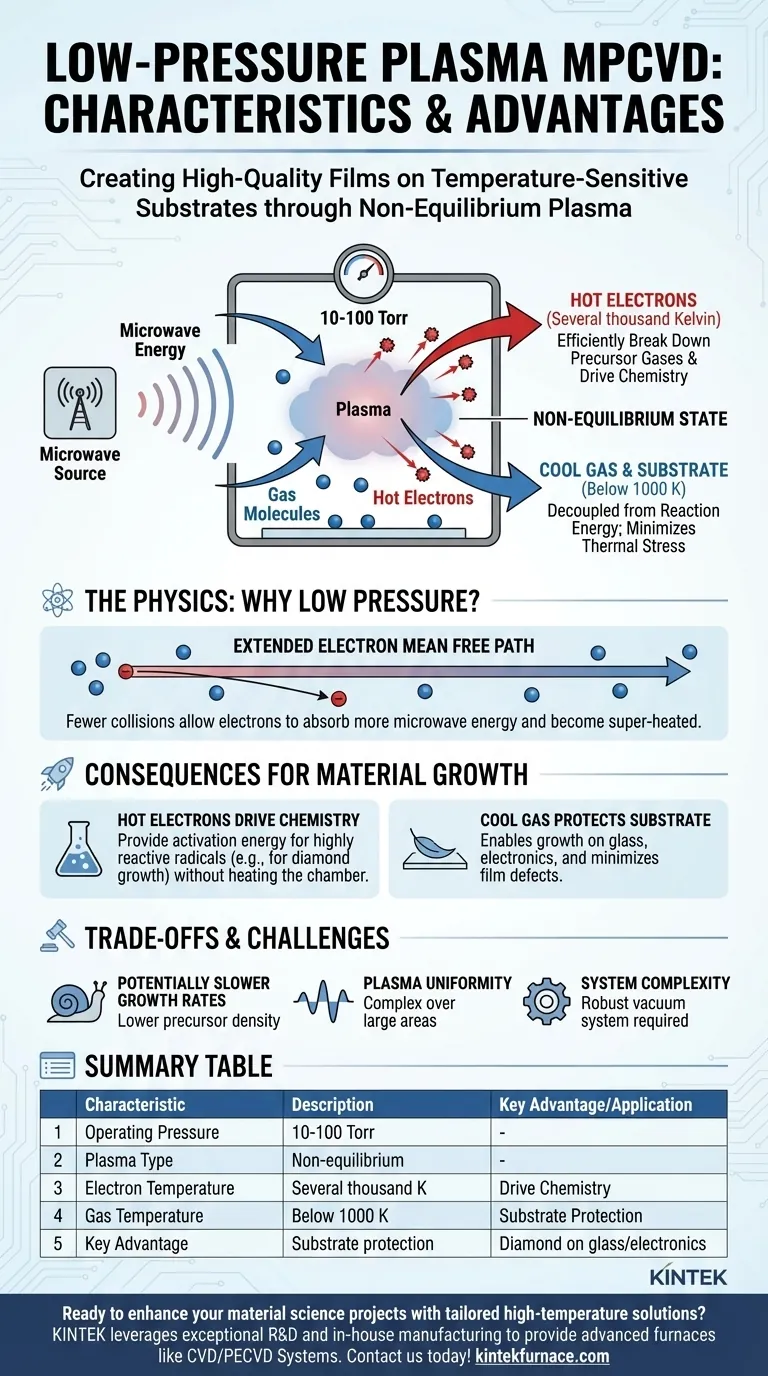

In short, low-pressure plasma MPCVD is defined by its operating pressure of 10-100 Torr, which creates a significant temperature difference between the system's electrons and its gas molecules. This non-equilibrium state allows for energetic chemical reactions to occur at a relatively low overall gas temperature.

The core principle of low-pressure MPCVD is using microwave energy to create a plasma where "hot" electrons do the chemical work, while the bulk gas and substrate remain "cool." This decouples the reaction energy from the system's thermal budget, enabling material growth on temperature-sensitive substrates.

The Physics of a Non-Equilibrium Plasma

Microwave Plasma Chemical Vapor Deposition (MPCVD) uses microwave energy to break down precursor gases into a reactive plasma, which then deposits a solid film onto a substrate. The "low-pressure" variant creates a very specific and useful plasma environment.

The Critical Role of Pressure

Operating at a low pressure of 10-100 Torr means there are far fewer gas molecules in the chamber compared to atmospheric pressure. This scarcity of particles is the direct cause of the system's unique characteristics.

Extended Electron Mean Free Path

Because the gas is less dense, an electron can travel much farther before colliding with a gas molecule. This distance is known as the electron mean free path.

A longer mean free path allows electrons to absorb more energy from the microwave field between each collision. This is how they become super-heated relative to the rest of the system.

Creating Two Distinct Temperatures

The result is a non-equilibrium plasma. The light, energetic electrons do not have enough time or collisions to efficiently transfer their energy to the much heavier and slower gas atoms or molecules.

This creates two separate temperature populations existing in the same space:

- High Electron Temperature: Reaching several thousand Kelvin.

- Low Gas Temperature: Remaining below 1000 K.

The Consequences for Material Growth

This two-temperature system is not just a scientific curiosity; it has profound and practical implications for depositing high-quality materials.

Hot Electrons Drive the Chemistry

The extremely high temperature of the electrons provides the energy needed to efficiently break down precursor gases (e.g., methane and hydrogen for diamond growth). This creates the highly reactive chemical species (radicals) necessary for film deposition.

Essentially, the electrons are the "engine" of the chemical reaction, providing activation energy without needing to heat the entire chamber.

Cool Gas Protects the Substrate

Because the bulk gas temperature remains relatively low (below 1000 K), the substrate being coated also stays cool. This is the single most important advantage of the low-pressure technique.

This characteristic allows for the growth of high-quality films, like diamond, on substrates that could not withstand the high temperatures of traditional thermal CVD processes, such as glass or certain electronics. It also helps minimize thermal stress and defects in the growing film.

Understanding the Trade-offs

While powerful, the low-pressure regime is not without its inherent challenges and trade-offs compared to higher-pressure alternatives.

Potentially Slower Growth Rates

The lower density of precursor gases at 10-100 Torr can sometimes lead to slower deposition rates. Since there are fewer reactive molecules available at any given moment, the film may build up more slowly than in a high-pressure system where precursor concentration is much higher.

Plasma Uniformity Challenges

Maintaining a stable and uniform plasma over a large substrate area can be more complex at lower pressures. Plasma tends to confine itself more readily, requiring careful reactor design to ensure the entire substrate is coated evenly.

System Complexity

Operating at these pressures requires a robust vacuum system capable of maintaining a stable, low-pressure environment. This adds a layer of complexity and cost compared to atmospheric pressure systems.

Making the Right Choice for Your Goal

Selecting the correct deposition regime depends entirely on the specific requirements of your material and substrate.

- If your primary focus is growth on temperature-sensitive substrates: Low-pressure MPCVD is the ideal choice, as it protects the substrate from thermal damage.

- If your primary focus is maximizing deposition speed: A higher-pressure MPCVD or a thermal CVD process might be more suitable, provided your substrate can tolerate the heat.

- If your primary focus is minimizing film stress: The lower thermal gradients in low-pressure MPCVD are highly advantageous for producing films with low internal stress.

Understanding the underlying plasma physics empowers you to select the precise tool needed to achieve your material science objectives.

Summary Table:

| Characteristic | Description |

|---|---|

| Operating Pressure | 10-100 Torr |

| Plasma Type | Non-equilibrium |

| Electron Temperature | Several thousand Kelvin |

| Gas Temperature | Below 1000 K |

| Key Advantage | Substrate protection for temperature-sensitive materials |

| Common Applications | Diamond growth on glass, electronics |

Ready to enhance your material science projects with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like CVD/PECVD Systems, designed for precision and customization. Whether you're working with temperature-sensitive substrates or need optimized growth conditions, our expertise ensures your unique requirements are met. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance