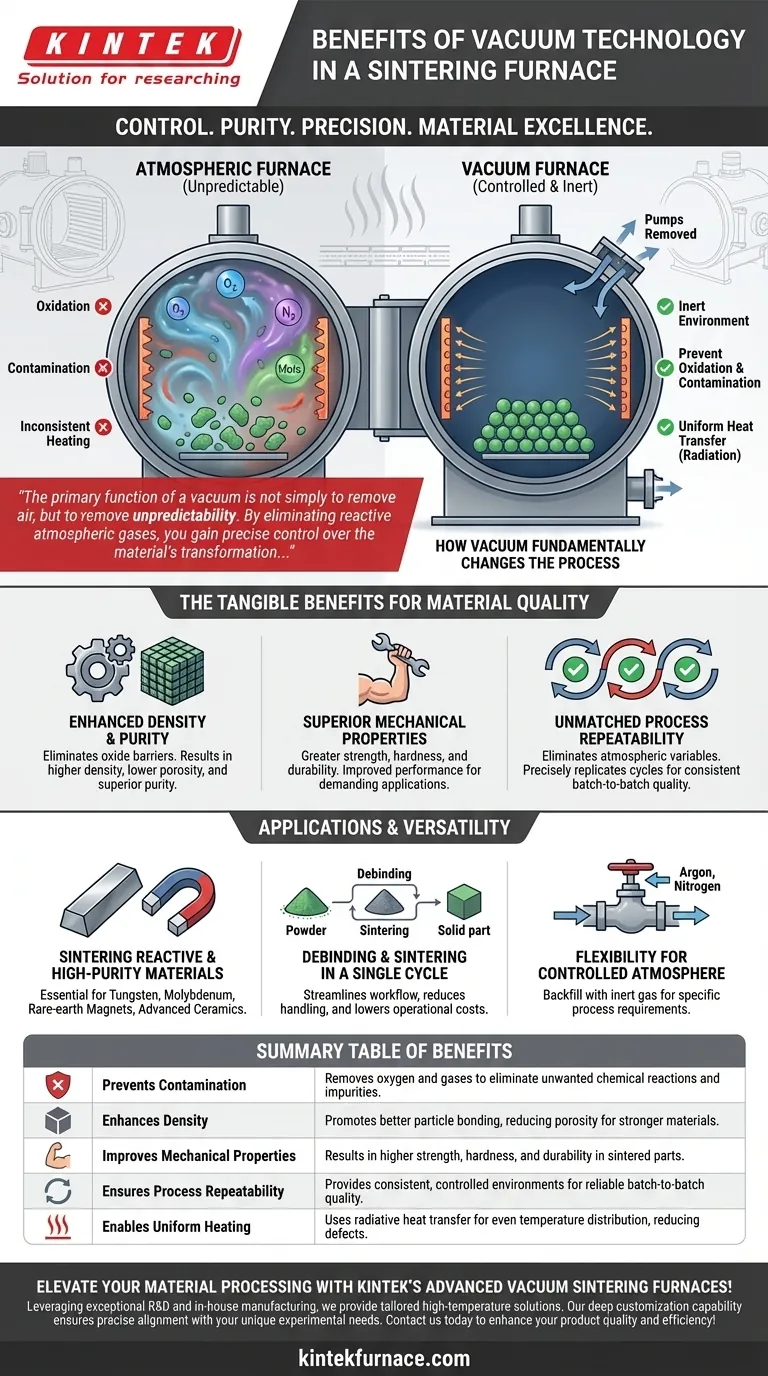

At its core, vacuum technology in a sintering furnace creates a highly controlled, inert environment. By removing atmospheric gases like oxygen and nitrogen, it prevents unwanted chemical reactions, eliminates contamination, and allows for more uniform heating, resulting in a final product with superior density, purity, and mechanical properties.

The primary function of a vacuum is not simply to remove air, but to remove unpredictability. By eliminating reactive atmospheric gases, you gain precise control over the material's transformation, ensuring the process is repeatable and the final product meets exacting specifications.

How Vacuum Fundamentally Changes the Sintering Process

Sintering uses heat and pressure to bond particles into a solid mass. The environment in which this happens is as critical as the temperature itself. A vacuum provides the ultimate level of environmental control.

Step 1: Creating the Inert Environment

The process begins by placing the material, or "green part," inside the furnace chamber. Powerful pumps then evacuate the chamber, removing the atmospheric gases. This vacuum state is the foundation for all subsequent benefits.

Step 2: Preventing Oxidation and Contamination

Oxygen is highly reactive at sintering temperatures. It readily forms oxides on the surface of material particles, which can inhibit proper bonding, leading to a weaker, more porous final product.

By removing the atmosphere, a vacuum furnace eliminates the oxygen, nitrogen, and water vapor that cause these unwanted reactions and contaminate the material.

Step 3: Enabling Uniform Heat Transfer

In a vacuum, heat is primarily transferred through radiation from the heating elements to the workpiece. This radiative heating is more uniform than convection, which can be inconsistent in a gas-filled furnace.

This uniformity ensures that the entire part reaches the target temperature consistently, reducing internal stresses and the risk of warpage or cracking.

The Tangible Benefits for Material Quality

This level of control translates directly into measurable improvements in the final product. The benefits are not theoretical; they are seen in the physical and mechanical properties of the sintered material.

Enhanced Density and Purity

Without oxide layers acting as barriers, the material particles can bond more effectively. This results in a final product with higher density and significantly lower porosity. For materials where purity is paramount, such as refractory metals, this is a non-negotiable advantage.

Superior Mechanical Properties

Higher density and purity directly lead to improved mechanical characteristics. Parts sintered in a vacuum consistently exhibit greater strength, hardness, and durability compared to those processed in an atmospheric furnace.

Unmatched Process Repeatability

Atmospheric conditions can fluctuate, introducing a variable that affects process outcomes. A vacuum eliminates this variable entirely. Each sintering cycle can be precisely replicated, ensuring consistent quality from batch to batch, which is critical for industrial production and medical applications like dental restorations.

Understanding the Applications and Versatility

The ability to create a pure environment makes vacuum sintering the ideal choice for demanding materials, but the technology is also surprisingly versatile.

Sintering Reactive and High-Purity Materials

Vacuum furnaces are essential for processing materials that are highly reactive with oxygen. This includes refractory metals like tungsten and molybdenum, cemented carbides, rare-earth magnets (samarium cobalt), and various advanced ceramic materials.

Debinding and Sintering in a Single Cycle

Modern vacuum furnaces can often perform both the debinding step (removing polymer binders) and the final sintering step in one continuous process. This streamlines the workflow, reduces handling, and lowers operational costs.

Flexibility for Controlled Atmosphere Sintering

A key advantage is that a vacuum furnace can also function as a controlled atmosphere furnace. After evacuating the chamber to remove contaminants, it can be backfilled with a specific, high-purity inert gas like Argon or Nitrogen. This provides ultimate flexibility for processes that require a specific partial pressure or gas environment.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your material and end-goal.

- If your primary focus is maximum purity and performance: For reactive metals, advanced ceramics, or medical-grade components, a high-vacuum furnace is the only way to achieve the required material properties.

- If your primary focus is process consistency and reducing defects: For applications like tool manufacturing or dental restorations, the repeatability of vacuum sintering minimizes costly rejects and ensures reliable outcomes.

- If your primary focus is research or versatile production: A furnace with both high-vacuum and controlled atmosphere capabilities offers the greatest flexibility to handle a wide range of materials and process requirements.

Ultimately, adopting vacuum technology is a decision to prioritize control and precision in your material processing.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Contamination | Removes oxygen and gases to eliminate unwanted chemical reactions and impurities. |

| Enhances Density | Promotes better particle bonding, reducing porosity for stronger materials. |

| Improves Mechanical Properties | Results in higher strength, hardness, and durability in sintered parts. |

| Ensures Process Repeatability | Provides consistent, controlled environments for reliable batch-to-batch quality. |

| Enables Uniform Heating | Uses radiative heat transfer for even temperature distribution, reducing defects. |

Elevate your material processing with KINTEK's advanced vacuum sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're working with reactive metals, ceramics, or medical components. Contact us today to discuss how our technology can enhance your product quality and efficiency!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance