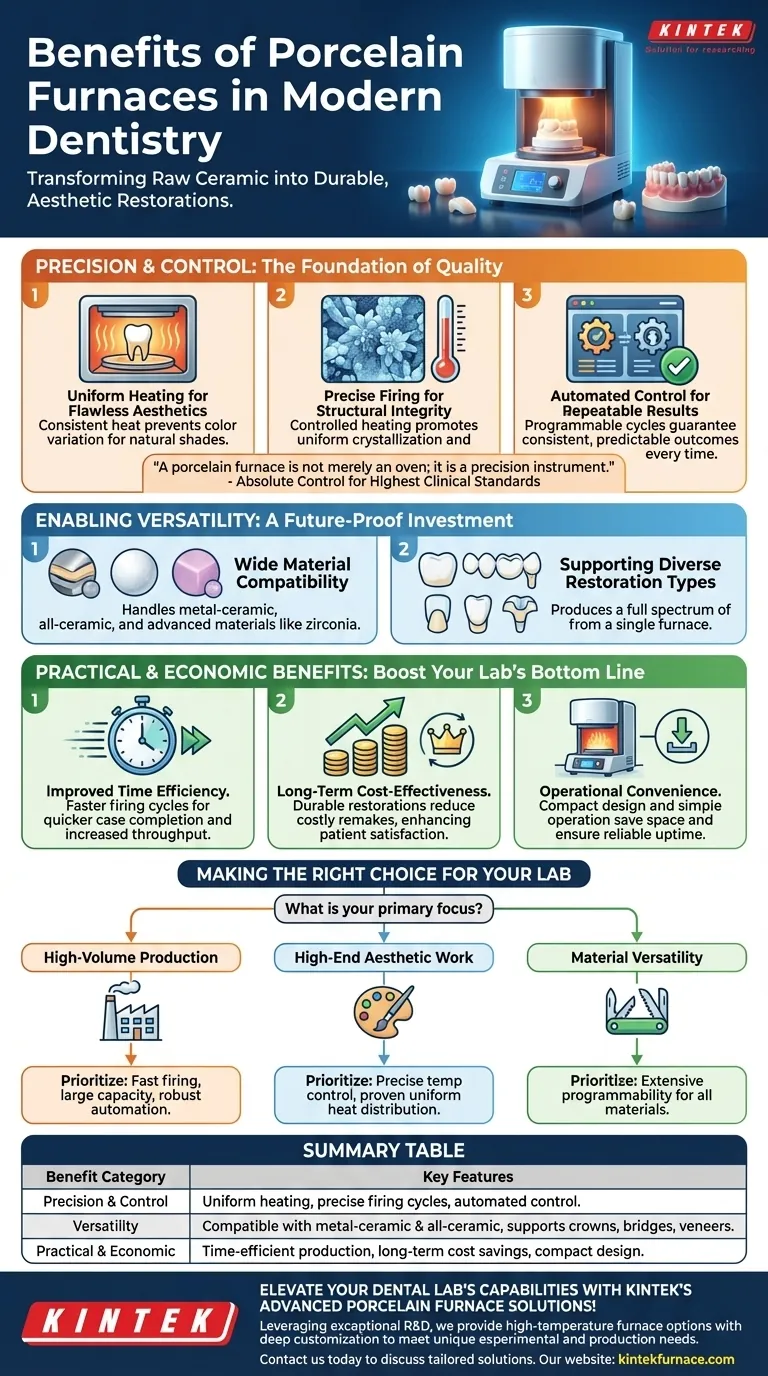

In modern dentistry, porcelain furnaces are the indispensable tools that transform raw ceramic materials into durable, aesthetic, and perfectly fitting restorations. The primary benefits are the ability to achieve accurate and consistent firing results, provide uniform heating for structural integrity, offer versatility across various ceramic materials, and improve the overall time and cost-effectiveness of the dental laboratory.

A porcelain furnace is not merely an oven; it is a precision instrument. It grants dental technicians absolute control over the material properties of a restoration, ensuring the final product is strong, visually flawless, and meets the highest clinical standards.

The Foundation of Quality: Precision and Control

The ultimate goal of any dental restoration is a perfect blend of form and function. A porcelain furnace is the critical component that makes this possible by ensuring every restoration is both strong and aesthetically pleasing.

Uniform Heating for Flawless Aesthetics

Consistent heat distribution is paramount for appearance. When a restoration heats unevenly, it can lead to noticeable color variations across its surface.

Modern furnaces provide uniform process heat, eliminating these temperature differences. This ensures the final restoration has a consistent, natural-looking shade that matches the patient's existing teeth.

Precise Firing for Structural Integrity

The durability of a ceramic restoration is determined at the microscopic level. A furnace's ability to precisely control the firing cycle directly impacts this.

Controlled heating promotes uniform crystallization and densification of the porcelain. This creates a homogenous structure that is mechanically strong and highly resistant to the cracking or chipping that can occur under oral conditions.

Automated Control for Repeatable Results

Consistency is the hallmark of a professional lab. Modern porcelain furnaces feature highly reliable, automatic process control systems.

Technicians can program specific firing cycles for different materials and restoration types. This automation guarantees that every unit, from the first to the last, is produced with the exact same predictable and high-quality result.

Enabling Versatility in Modern Restorations

The field of dental materials is constantly evolving. A key benefit of a quality porcelain furnace is its ability to adapt to a wide range of materials and applications, making it a future-proof investment for any dental lab.

Compatibility with a Wide Range of Materials

Today's furnaces are not limited to a single type of porcelain. They are designed to be versatile, handling both metal-ceramic and all-ceramic restorations.

This includes firing precious and non-precious metal frameworks, as well as sintering advanced materials like zirconia and lithium disilicate.

Supporting Diverse Restoration Types

This material versatility allows labs to produce a full spectrum of dental prosthetics.

A single furnace can be used to fire dental crowns, bridges, inlays, and laminate veneers. This flexibility allows a lab to meet the functional and aesthetic demands of nearly any clinical case.

Understanding the Practical and Economic Benefits

Beyond the clinical quality of the final product, a porcelain furnace delivers significant operational advantages that impact a lab's bottom line and workflow efficiency.

Improved Time Efficiency

In a competitive environment, turnaround time matters. Modern furnaces are engineered for time-efficient production, enabling faster firing cycles without sacrificing quality.

This allows labs to complete cases more quickly, improving service to dentists and increasing the overall throughput and profitability of the laboratory.

Long-Term Cost-Effectiveness

While a furnace represents a significant initial investment, it provides value through the creation of durable, long-lasting restorations.

High-quality outcomes reduce the costly and time-consuming need for remakes or adjustments. This reliability leads to greater patient satisfaction and reinforces the lab's reputation for excellence.

Operational Convenience

Furnaces are also designed with the user in mind. Many feature a compact design to save valuable floor space, along with systems for easy loading and unloading.

Simple operation and maintenance routines ensure the equipment remains a reliable asset rather than a source of downtime, even in high-volume production environments.

Making the Right Choice for Your Lab

Selecting the right furnace requires aligning its capabilities with your specific operational priorities.

- If your primary focus is high-volume production: Prioritize a furnace known for its fast firing cycles, large capacity, and robust automation features.

- If your primary focus is high-end aesthetic work: Seek a furnace renowned for its exceptionally precise temperature control and proven uniform heat distribution.

- If your primary focus is material versatility: Ensure the model you choose offers extensive programmability to handle everything from traditional metal-ceramics to modern zirconia and pressable ceramics.

Ultimately, the right porcelain furnace is a cornerstone investment that empowers your lab to consistently deliver exceptional results.

Summary Table:

| Benefit Category | Key Features |

|---|---|

| Precision & Control | Uniform heating, precise firing cycles, automated control for consistent results |

| Versatility | Compatible with metal-ceramic and all-ceramic materials, supports crowns, bridges, veneers |

| Practical & Economic | Time-efficient production, long-term cost savings, compact design for easy operation |

Elevate your dental lab's capabilities with KINTEK's advanced porcelain furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production needs, delivering durable, aesthetic restorations with improved efficiency. Contact us today to discuss how our tailored solutions can enhance your workflow and boost profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab