The primary benefit of miniaturization in IGBT induction melting furnaces is a significant reduction in both spatial footprint and operational cost. By leveraging modern solid-state IGBT (Insulated-Gate Bipolar Transistor) technology, these compact furnaces deliver high efficiency and precise control without the massive infrastructure demands of traditional melting systems, making them accessible to a wider range of facilities.

The true advantage of miniaturization is not just about saving space. It’s about democratizing access to advanced, efficient, and safer melting technology for operations that were previously limited by high capital costs and large facility requirements.

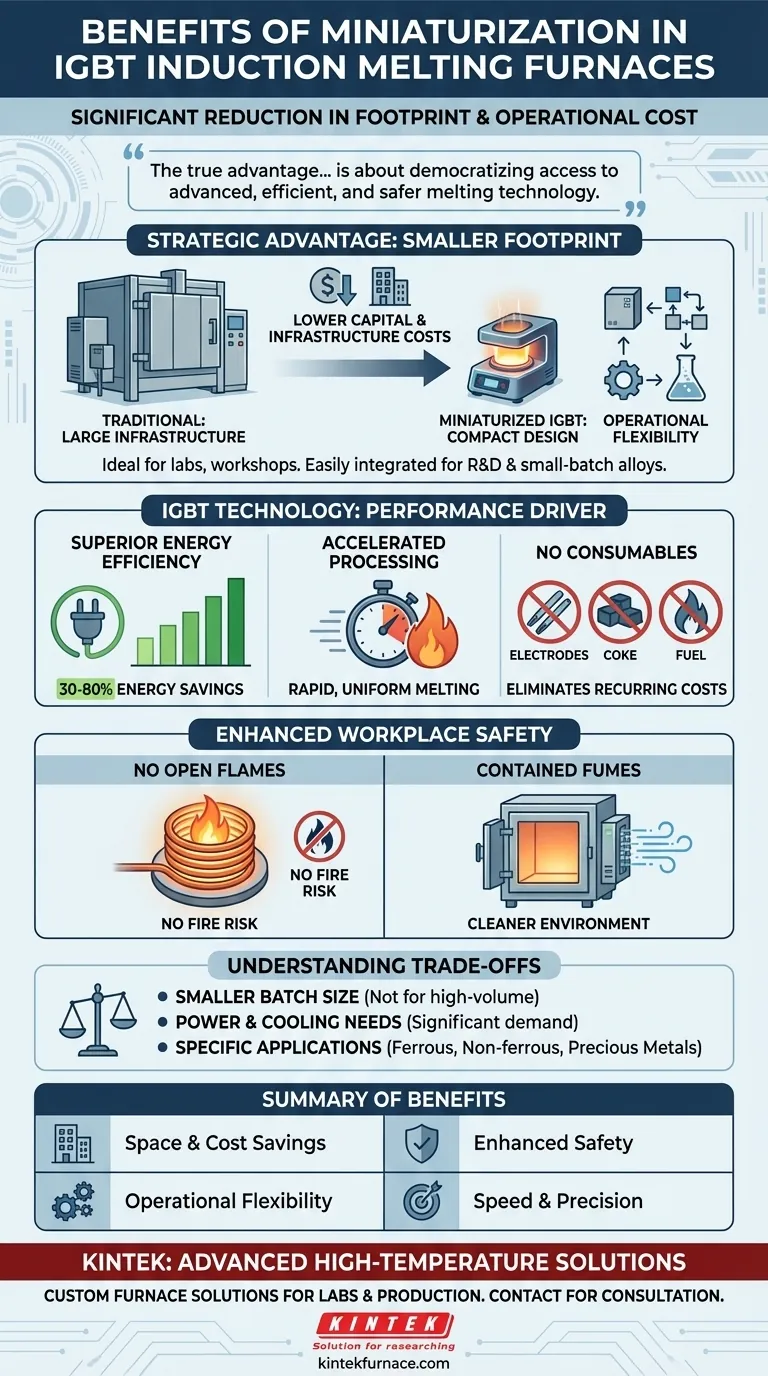

The Strategic Advantage of a Smaller Footprint

Miniaturization directly translates to tangible business benefits, primarily by reducing the physical and financial barriers to entry for advanced melting operations.

Reducing Infrastructure and Capital Costs

A compact design fundamentally lowers the cost of implementation. It allows the furnace to be installed in smaller production facilities, workshops, or laboratories, often avoiding the need for expensive new construction or major facility modifications.

This smaller footprint reduces the initial capital outlay required for both the equipment and the space it occupies, lowering the overall investment risk.

Enabling Operational Flexibility

Smaller furnaces can be more easily integrated into existing production lines or cellular manufacturing layouts. Their portability allows businesses to reconfigure floor space as operational needs change.

This is particularly valuable for research and development, prototyping, or the production of specialized, small-batch alloys where a large, dedicated furnace would be impractical and inefficient.

How IGBT Technology Drives Performance

The benefits of a compact form factor are made possible by the efficiency of the underlying IGBT power supply. This technology is what allows a small furnace to perform with impressive power and precision.

Unlocking Superior Energy Efficiency

IGBT-based systems offer dramatic energy savings, often between 30% and 80%, compared to older fuel-fired or resistance-based furnaces.

This efficiency comes from precise frequency control, which optimizes energy transfer to the metal, and the near-elimination of standby heat loss. The furnace consumes significant power only when it is actively melting.

Accelerating Processing Times

Induction heating is incredibly fast, bringing metal to its melting point far quicker than traditional methods. The electromagnetic field directly heats the target material from within, ensuring rapid and uniform melting.

This speed, combined with precise temperature control, improves throughput and allows for more consistent metallurgical results.

Eliminating Consumables and Fuel

Unlike arc or cupola furnaces, IGBT induction systems require no electrodes, coke, or combustible fuel. This simplifies operations, lowers recurring costs, and eliminates the safety hazards associated with storing and handling fuel.

Understanding the Trade-offs

While the benefits are significant, it is crucial to understand the limitations inherent in a smaller system.

Batch Size and Throughput

The most obvious trade-off is melting capacity. A miniaturized furnace is, by definition, designed for smaller batches. It is not a suitable replacement for a large-scale foundry requiring high-volume, continuous melts of several tons at a time.

Power and Cooling Requirements

Even a small induction furnace has significant electrical power requirements. You must ensure your facility's electrical service can support the unit's peak demand. Furthermore, the induction coils and power supply generate heat and require a reliable water-cooling system.

Scope of Application

While versatile, these furnaces are best suited for melting ferrous and non-ferrous metals, precious metals, and creating specialized alloys. They are not a universal solution for all heating applications and should be chosen based on the specific materials you intend to process.

Enhancing Workplace Safety

A core benefit of induction technology, maintained in miniaturized models, is a dramatic improvement in operational safety.

Eliminating Open Flames

Induction melting is a flameless process. This inherently reduces the risk of fires and severe burns associated with fuel-fired furnaces.

Containing Harmful Fumes

Because the process can occur in a controlled or sealed environment, the release of toxic fumes and smoke is minimized. This creates a cleaner, safer breathing environment for operators compared to open-flame systems.

Making the Right Choice for Your Operation

Choosing the right furnace requires aligning the technology's benefits with your primary operational goals.

- If your primary focus is cost reduction and space optimization: A miniaturized IGBT furnace is an ideal solution for minimizing both upfront infrastructure costs and long-term energy expenses.

- If your primary focus is R&D or specialized alloy production: The precise control, rapid heating, and smaller batch sizes of a compact furnace offer unmatched flexibility for experimentation and high-value manufacturing.

- If your primary focus is high-volume, continuous production: You must carefully evaluate if the throughput of a small furnace (or multiple units) can meet your targets, as a larger-capacity system may be necessary.

Ultimately, miniaturization makes the powerful benefits of IGBT induction technology more accessible, efficient, and safer for a broader range of modern industrial applications.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Space & Cost Savings | Reduces infrastructure and capital investment. |

| Energy Efficiency | Offers 30-80% energy savings over traditional furnaces. |

| Operational Flexibility | Enables easy integration into labs and existing production lines. |

| Enhanced Safety | Flameless process minimizes fire risks and contains harmful fumes. |

| Speed & Precision | Provides rapid, uniform heating with precise temperature control. |

Ready to integrate a high-efficiency, compact melting solution into your lab or production line?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you achieve superior results with a furnace tailored to your specific needs. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?