At their core, graphite crucible furnaces provide a combination of rapid heating, exceptional temperature uniformity, and precise high-temperature control. This makes them indispensable for applications demanding stringent thermal management and consistent, high-purity material properties, from metal melting to the synthesis of advanced materials.

While many furnaces can achieve high temperatures, the graphite crucible furnace's primary advantage is its ability to deliver unmatched temperature stability and uniformity at extreme heats. This makes it the definitive choice for processes where material integrity and predictable outcomes are non-negotiable.

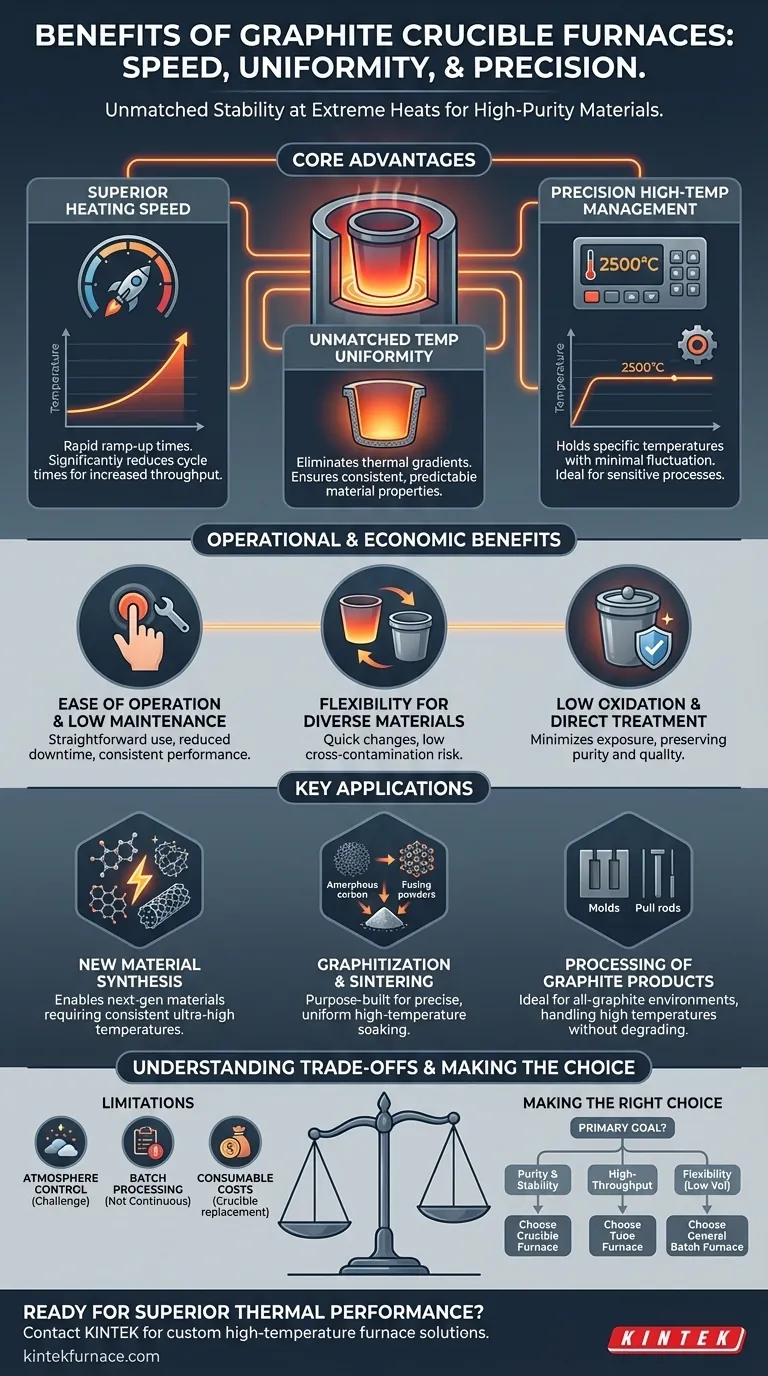

The Core Advantages: Speed, Uniformity, and Control

A graphite crucible furnace's performance is defined by its superior thermal characteristics. These are not just minor improvements; they are fundamental to achieving high-quality results in demanding applications.

Superior Heating Speed

The graphite heating element allows for exceptionally fast ramp-up times compared to many other furnace types. This significantly reduces cycle times, increasing operational throughput and efficiency.

Unmatched Temperature Uniformity

These furnaces are engineered to eliminate hot and cold spots within the crucible. This ensures that the entire batch of material is processed at the exact same temperature, leading to highly consistent and predictable material properties.

Precision High-Temperature Management

The ability to hold a specific high temperature with minimal fluctuation is critical. Graphite crucible furnaces excel at this, making them ideal for sensitive processes like crystal growth, sintering, or producing advanced alloys where slight deviations can ruin the result.

Operational and Economic Benefits

Beyond thermal performance, these furnaces offer practical advantages that make them a strategic choice for both research labs and industrial production.

Ease of Operation and Low Maintenance

Crucible furnaces are generally straightforward to operate, requiring minimal specialized training. Their design often leads to lower maintenance requirements, reducing downtime and ensuring consistent performance over time.

Flexibility for Diverse Materials

The crucible design allows for quick changes between different materials or alloys with a low risk of cross-contamination. Simply swapping the crucible enables a high degree of process flexibility.

Low Oxidation and Direct Treatment

Melting or treating materials directly within the crucible minimizes their exposure to outside atmospheres. This results in very low oxidation losses, preserving the purity and final quality of the material.

Where Graphite Crucible Furnaces Excel

These furnaces are not just for melting metal; their unique capabilities make them critical tools in advanced material science and manufacturing.

Enabling New Material Synthesis

The production of next-generation materials like graphene and carbon nanotubes often requires the consistent, ultra-high temperatures that graphite crucible furnaces provide, making them a key enabler of technological innovation.

Critical for Graphitization and Sintering

Processes like graphitization (converting amorphous carbon to crystalline graphite) and sintering (fusing powders into a solid mass) depend on precise, uniform high-temperature soaking. The graphite crucible furnace is purpose-built for these tasks.

Processing of Graphite Products

These furnaces are also used in the manufacturing of other graphite components, such as casting molds and pull rods. Their ability to handle high temperatures without degrading makes them ideal for an all-graphite processing environment.

Understanding the Trade-offs

No single technology is a universal solution. Understanding the limitations of a graphite crucible furnace is crucial for making an objective decision.

Atmosphere Control

While excellent for purity, achieving a highly controlled or specific gas atmosphere can be more challenging than in a sealed tube furnace. The crucible is often open or loosely covered, limiting its use for processes requiring a strict vacuum or reactive gas environment.

Batch Processing Throughput

By their nature, crucible furnaces are batch processors. For applications requiring high-volume, continuous production, a system like a tube furnace may be better suited for automated, continuous material flow.

Consumable Costs

The graphite crucible itself is a consumable component with a finite lifespan. Its replacement represents an ongoing operational cost that must be factored into the total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct furnace requires aligning the technology's strengths with your primary goal.

- If your primary focus is material purity and thermal stability at extreme temperatures: The graphite crucible furnace's uniform heating and inert processing environment are unparalleled.

- If your primary focus is high-throughput, continuous production: A tube furnace designed for continuous flow may offer better efficiency for your workflow.

- If your primary focus is flexible heat treatment of varied parts in low volumes: A general-purpose batch furnace might provide the necessary versatility for a lower initial investment.

Ultimately, choosing a graphite crucible furnace is an investment in process control, material purity, and final product quality.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Heating Speed | Rapid ramp-up times reduce cycle times and increase throughput. |

| Temperature Uniformity | Eliminates hot/cold spots for consistent, predictable material properties. |

| High-Temperature Control | Precise, stable temperature holding for sensitive processes like sintering. |

| Operational Flexibility | Easy crucible swapping allows for diverse materials with low contamination risk. |

| Material Purity | Low oxidation losses preserve the quality and purity of the final product. |

Ready to achieve superior thermal performance and material purity in your lab or production line?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like yours.

Contact us today to discuss how a custom high-temperature furnace solution can enhance your process control and final product quality.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD