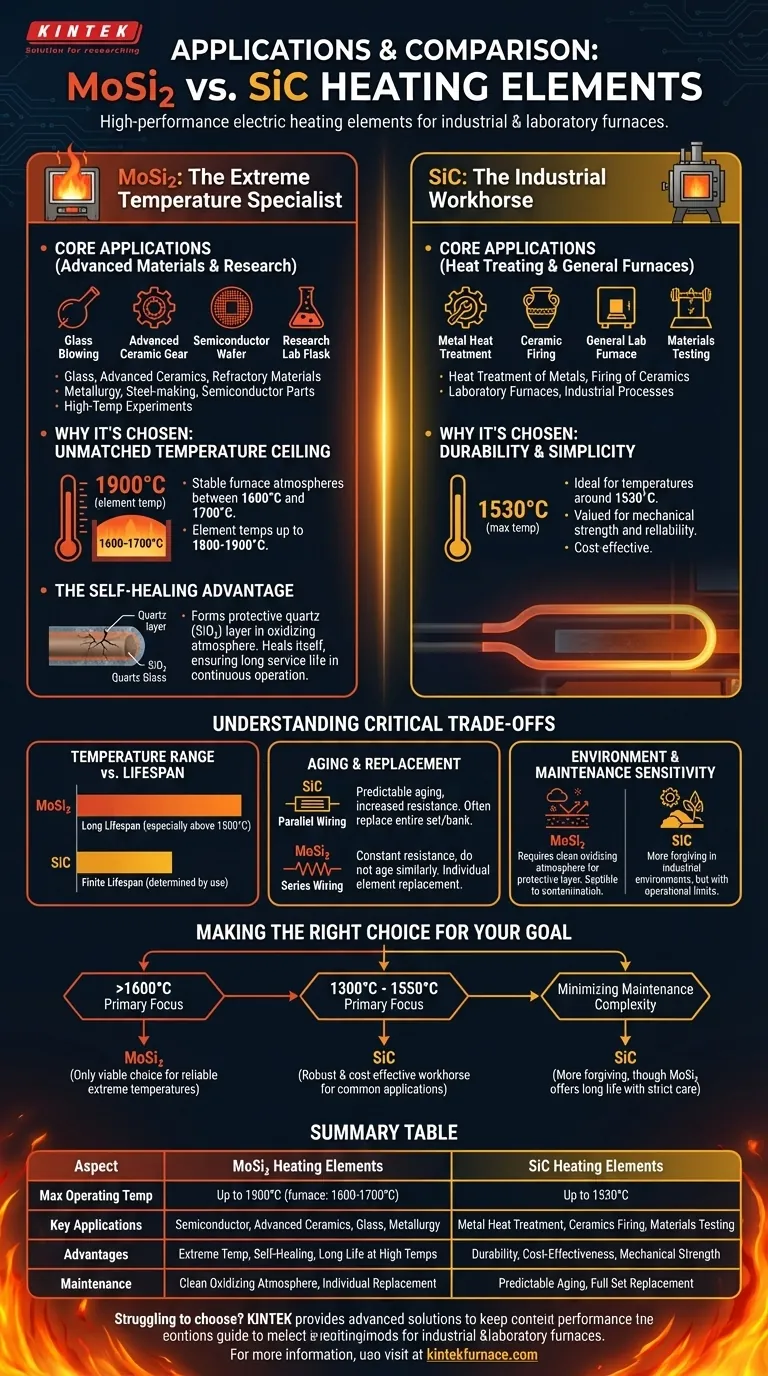

At their core, Molybdenum Disilicide (MoSi₂) and Silicon Carbide (SiC) are both high-performance electric heating elements designed for industrial and laboratory furnaces. MoSi₂ elements are chosen for the most extreme temperature applications above 1600°C, such as in semiconductor, advanced ceramic, and glass production. Silicon Carbide serves as a robust workhorse for a slightly lower, yet still very high, temperature range up to about 1530°C in applications like metal heat treatment and materials testing.

The decision between MoSi₂ and SiC is not about which is universally "better," but which is precisely suited for your target temperature range and operating environment. MoSi₂ excels at extreme heat but requires careful maintenance, while SiC is a durable option for the vast majority of high-temperature industrial processes.

MoSi₂: The Extreme Temperature Specialist

Molybdenum Disilicide (MoSi₂) elements are renowned for their ability to perform reliably at furnace temperatures that other elements cannot withstand. This makes them essential in highly specialized fields.

Core Applications: Advanced Materials & Research

MoSi₂ is the element of choice for furnaces used in the research and production of glass, advanced ceramics, and refractory materials.

They are also critical in metallurgy, steel-making, and the manufacturing of electronic parts and semiconductor materials. In research settings, they enable high-temperature experiments and new material synthesis.

Why It's Chosen: Unmatched Temperature Ceiling

The primary advantage of MoSi₂ is its maximum operating temperature. The elements themselves can reach 1800-1900°C, allowing for stable furnace atmospheres between 1600°C and 1700°C.

This capability is non-negotiable for processes that require sintering or melting points beyond the reach of SiC or metallic elements.

The Self-Healing Advantage

MoSi₂ elements exhibit robust oxidation resistance at high temperatures. When exposed to an oxidizing atmosphere, they form a protective, passive layer of quartz glass (SiO₂) on their surface.

If this layer is damaged, the underlying material re-oxidizes to "heal" the protective coating, contributing to a long service life in continuous operation.

Silicon Carbide (SiC): The Industrial Workhorse

While MoSi₂ dominates the highest temperature niches, Silicon Carbide (SiC) elements are a proven and widely used solution for a broad range of industrial heating processes.

Core Applications: Heat Treating and General Furnaces

SiC elements are frequently used in applications requiring a maximum furnace temperature of around 1530°C.

This makes them ideal for the heat treatment of metals, firing of ceramics, and in various laboratory and industrial furnaces where extreme temperatures are not the primary requirement.

Why It's Chosen: Durability and Simplicity

SiC elements are valued for their mechanical strength and reliability within their specified temperature band. They represent a cost-effective and durable solution for many common high-temperature tasks.

Understanding the Critical Trade-offs

Choosing the correct element requires a clear understanding of their distinct operational differences, which directly impact furnace design, maintenance, and longevity.

Temperature Range vs. Lifespan

MoSi₂ elements can last longer than SiC elements when operated consistently above 1500°C, where their protective layer is most effective.

Conversely, SiC elements have a finite lifespan determined by use, and their resistance gradually increases over time. This aging process is a predictable part of their operational life.

The Impact of Aging and Replacement

When a SiC element fails, its increased resistance means you often must replace the entire set or bank of elements to maintain a balanced electrical load. They are typically wired in parallel.

MoSi₂ elements do not age in the same way, and their resistance remains relatively constant. This allows for individual element replacement, as new and old elements are compatible. They are typically wired in series.

Environmental and Maintenance Sensitivity

The performance of MoSi₂ is highly dependent on a clean, oxidizing atmosphere to maintain its protective layer. They are more susceptible to contamination and can be damaged by certain chemical environments, dissolving in nitric and hydrofluoric acid.

SiC elements are generally considered more forgiving in a wider range of industrial environments, though they have their own operational limits.

Making the Right Choice for Your Goal

Your final decision must be guided by the specific thermal and chemical demands of your process.

- If your primary focus is operating above 1600°C: MoSi₂ is the only technically viable choice for achieving these extreme temperatures reliably.

- If your primary focus is processing between 1300°C and 1550°C: SiC is often the more robust and cost-effective workhorse for these common industrial applications.

- If your primary focus is minimizing maintenance complexity: SiC can be more forgiving, whereas MoSi₂ demands strict attention to furnace purity and atmosphere control to deliver its long service life.

Ultimately, selecting the right heating element is about matching the tool's specific strengths to the unique demands of your application.

Summary Table:

| Aspect | MoSi2 Heating Elements | SiC Heating Elements |

|---|---|---|

| Max Operating Temp | Up to 1900°C (furnace: 1600-1700°C) | Up to 1530°C |

| Key Applications | Semiconductor, advanced ceramics, glass production, metallurgy | Metal heat treatment, ceramics firing, materials testing |

| Advantages | Extreme temperature capability, self-healing oxidation resistance, long life at high temps | Durability, cost-effectiveness, mechanical strength |

| Maintenance | Requires clean oxidizing atmosphere, individual element replacement | Predictable aging, full set replacement often needed |

Struggling to choose the right heating element for your high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you need MoSi2 for extreme temperatures or SiC for industrial durability. Contact us today to optimize your process and boost efficiency!

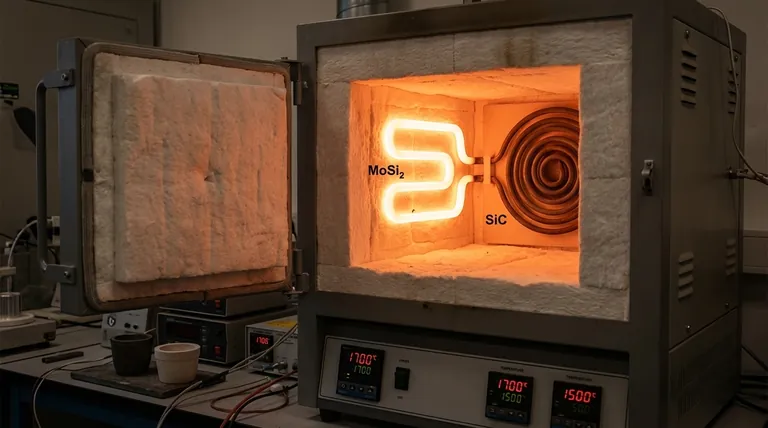

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is Serpentine Technology in heating elements? High-Temp, High-Stakes Heating Solutions

- What are the operating temperature limits for 'one piece' and 'three piece' SiC resistors in air or inert atmospheres? Ensure Longevity and Performance

- What are the limitations of Copper Nickel alloys for heating applications? Key Temperature and Performance Insights

- What are the key properties of effective heating elements? Optimize Your Heat Generation for Efficiency and Longevity

- What are the typical applications of Molybdenum Disilicide (MoSi₂)? Unlock High-Temp Heating Solutions

- How do alkali, alkaline oxides, and melting metals affect silicon carbide heating elements? Prevent Damage for Long Lifespan

- What are the ideal applications for MoSi2 heating elements? Achieve Reliable High-Temp Performance

- What are the typical applications of SC Type Silicon Carbide Heating Elements? Ensure Uniform Heat for Industrial Processes