In short, an intelligent operation interface on a porcelain furnace transforms a complex, manual process into a simple, predictable, and highly repeatable one. It provides significant advantages in ease of use through high-definition touch screens, guarantees consistent results with pre-set programs and automatic temperature control, and offers advanced customization for various dental materials.

Firing dental ceramics is a science where precision is non-negotiable. The core value of an intelligent interface is that it moves this critical task from an art form reliant on individual skill to a standardized, electronically controlled process, directly improving the quality, consistency, and efficiency of your lab's output.

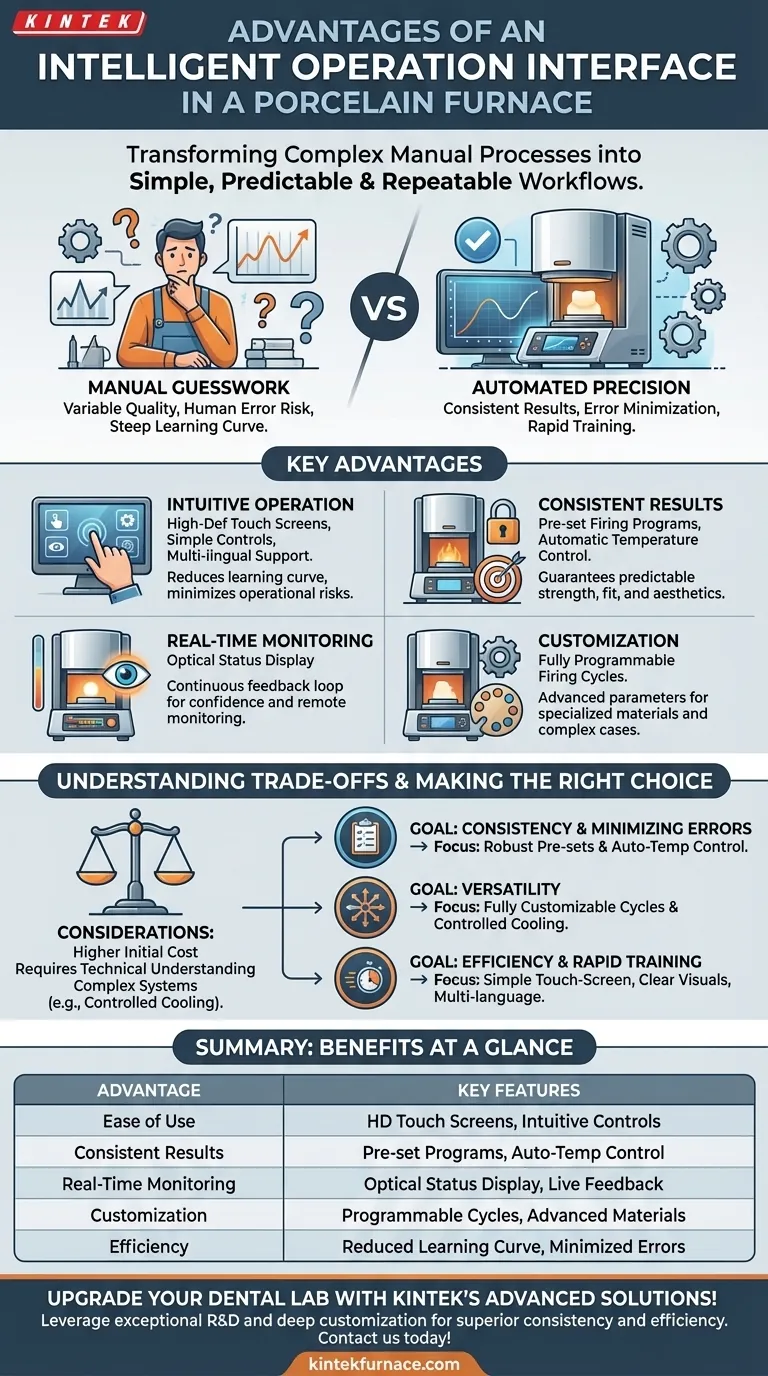

From Manual Guesswork to Automated Precision

The primary function of an intelligent interface is to remove the variables and potential for human error that can compromise the quality of a dental restoration. It achieves this by simplifying control while simultaneously increasing precision.

Intuitive Operation for All Skill Levels

Modern interfaces are built around high-definition touch screens with intuitive controls. This design is often multi-lingual and straightforward enough for even minimally trained technicians to operate confidently.

The result is a significantly reduced learning curve, allowing new team members to become productive more quickly and minimizing the risk of operational errors.

Guaranteeing Consistent, Repeatable Results

Perhaps the most significant advantage is the ability to achieve identical results time after time. Intelligent furnaces use pre-set firing programs for common materials like zirconia or lithium disilicate.

This, combined with automatic temperature adjustment, takes the guesswork out of the firing cycle. The furnace, not the operator, ensures the precise temperature curve is followed perfectly, leading to predictable strength, fit, and aesthetics in the final restoration.

Real-Time Monitoring and Control

An intelligent interface provides a clear, optical status display that shows the operator exactly what is happening inside the furnace in real-time.

This continuous feedback loop gives technicians the confidence that the cycle is running correctly and allows them to monitor progress without needing to be right next to the machine.

Customization for Advanced Materials

While pre-set programs handle common tasks, advanced labs require flexibility. Intelligent interfaces allow technicians to create and save fully programmable firing cycles.

This is essential for fabricating restorations from specialized materials or for adapting to the specific requirements of a complex case. The interface enables customization of every parameter, from heating rates to hold times and controlled cooling.

Understanding the Trade-offs

While the benefits are substantial, it's crucial to view these advanced features within the context of your lab's specific needs and to be aware of the associated considerations.

Cost vs. Capability

Furnaces with more sophisticated interfaces and programmable features typically come with a higher initial investment. The decision should be based on a clear analysis of the return on investment through reduced remakes, material savings, and improved efficiency.

Automation Is Not a Substitute for Knowledge

An intelligent interface is a powerful tool, but it does not replace the technician's fundamental understanding of dental ceramics. Operators must still know why certain parameters are chosen to troubleshoot issues effectively and handle non-standard situations.

Controlled Cooling and System Complexity

Advanced features like controlled cooling systems add another layer of sophistication. While invaluable for preventing cracks and distortion in all-ceramic restorations, they also represent another component that must be maintained and understood, adding to the device's overall technical complexity.

Making the Right Choice for Your Goal

The ideal furnace interface depends entirely on the primary objectives of your dental laboratory.

- If your primary focus is consistency and minimizing errors: Prioritize a furnace with a robust library of pre-set firing programs and proven automatic temperature control.

- If your primary focus is versatility for advanced restorations: Ensure the interface allows for fully customizable, savable firing cycles and features a controlled cooling function.

- If your primary focus is efficiency and rapid training: Look for a simple, high-definition touch-screen interface with clear graphical displays and multi-language support.

Ultimately, the right intelligent interface empowers your technicians to deliver the highest quality restorations with unparalleled predictability and confidence.

Summary Table:

| Advantage | Key Features |

|---|---|

| Ease of Use | High-definition touch screens, intuitive controls, multi-lingual support |

| Consistent Results | Pre-set firing programs, automatic temperature control |

| Real-Time Monitoring | Optical status display for live feedback |

| Customization | Fully programmable firing cycles for advanced materials |

| Efficiency | Reduced learning curve, minimized errors, improved productivity |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your needs. Our strong deep customization capability ensures precise solutions for unique experimental requirements, helping you achieve superior consistency and efficiency in ceramic restorations. Contact us today to discuss how we can enhance your lab's performance!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency