The key advantages of modern muffle furnace heating elements are their ability to reach significantly higher operating temperatures, provide more uniform heat distribution, and improve overall process efficiency. These advancements have expanded the furnace's capabilities from simple heat treatment to sophisticated metallurgical applications that were previously not possible.

The evolution in heating element materials has transformed the muffle furnace from a basic high-heat chamber into a precision tool. Modern elements like molybdenum disilicide are not just an upgrade; they are an enabling technology for advanced industrial processes like metal injection molding.

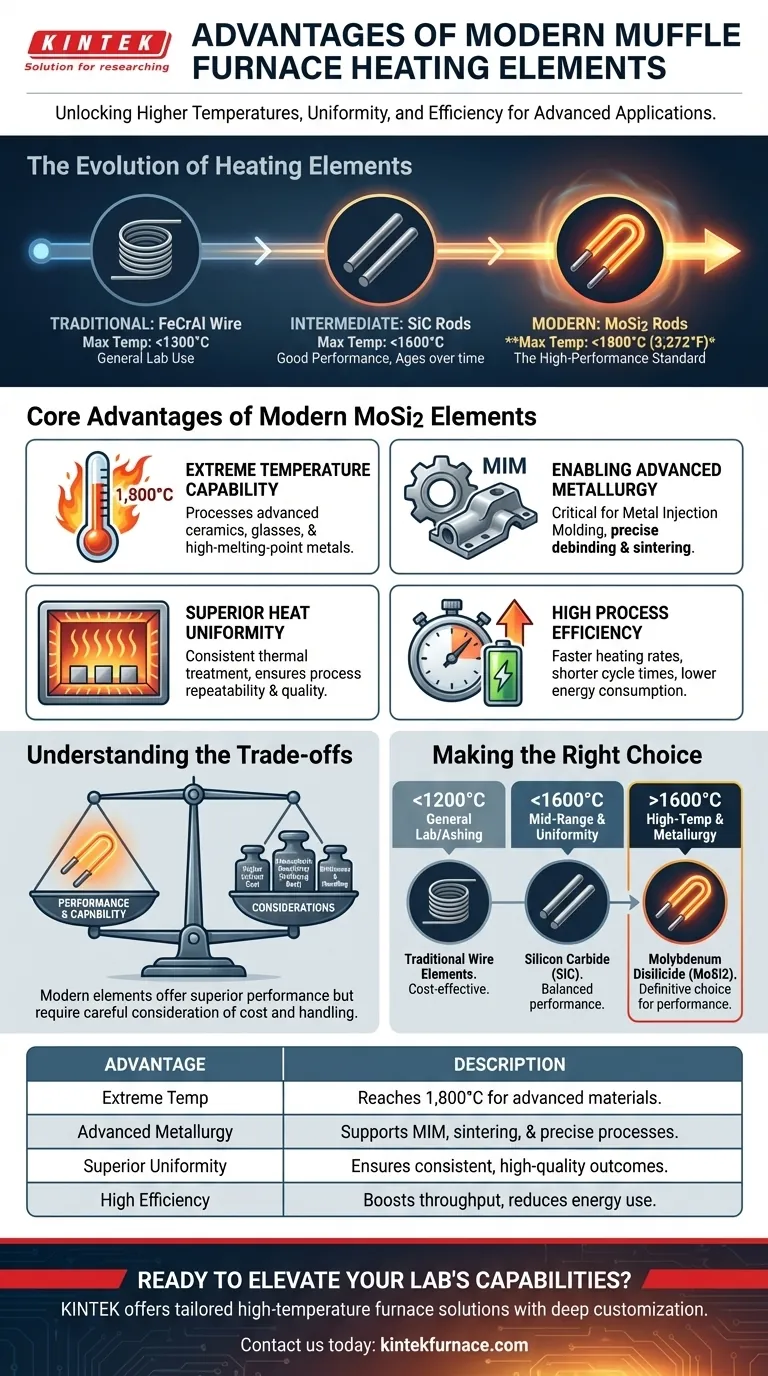

The Evolution of Furnace Heating Elements

To understand the advantages of modern elements, it's helpful to compare them to their predecessors. The type of element used directly dictates the furnace's performance capabilities.

Traditional: Electric Wire Elements (FeCrAl)

Traditional muffle furnaces often use iron-chromium-aluminum (FeCrAl) alloy wires, sometimes known as Kanthal. These are reliable and cost-effective for general-purpose applications.

However, their primary limitation is a maximum operating temperature typically around 1200-1300°C, which is insufficient for many modern material science and metallurgy needs.

Intermediate: Silicon Carbide (SiC) Rods

Silicon carbide rods represent a significant step up from wire elements. They can operate at higher temperatures, often up to 1600°C.

SiC elements offer good performance and are used in many industrial and laboratory settings. However, they can age over time, with their electrical resistance increasing, which requires periodic adjustments to the power supply.

Modern: Molybdenum Disilicide (MoSi2) Rods

Molybdenum disilicide (often abbreviated as MoSi2) is the current standard for high-performance, high-temperature muffle furnaces.

These elements can operate reliably at extreme temperatures, reaching up to 1,800°C (3,272°F). This capability is the driving force behind the key advantages of modern furnaces.

Core Advantages of Modern MoSi2 Elements

The use of materials like molybdenum disilicide provides clear, measurable benefits that unlock new processing capabilities.

Advantage 1: Extreme Temperature Capability

The ability to reach 1,800°C is the most significant advantage. This opens the door to processing advanced ceramics, glasses, and metals with very high melting points.

Advantage 2: Enabling Advanced Metallurgy

This high-temperature capability directly enables sophisticated processes that are critical in modern manufacturing.

Examples include debinding and sintering for metal injection molding (MIM), where precise temperature control at very high levels is required to produce dense, final-shape metal parts.

Advantage 3: Superior Heat Uniformity

Modern heating elements are engineered for exceptional temperature consistency throughout the furnace chamber.

This uniformity is critical for process repeatability and ensuring that every part in a batch receives the same thermal treatment, preventing defects and improving quality.

Advantage 4: High Process Efficiency

MoSi2 elements can often support faster heating rates compared to older materials. This shortens cycle times, increasing laboratory or factory throughput and reducing energy consumption per cycle.

Understanding the Trade-offs

While modern elements offer superior performance, they come with a different set of considerations compared to traditional materials.

Upfront Cost

Advanced materials like silicon carbide and molybdenum disilicide are more expensive than traditional FeCrAl wire elements. The initial investment in the furnace will be higher.

Atmospheric Sensitivity

MoSi2 elements perform best and have the longest life in oxidizing atmospheres (like air), where they form a protective, self-healing layer of silica glass on their surface. Their performance can be compromised in certain reducing atmospheres.

Brittleness and Handling

Unlike ductile metal wires, SiC and MoSi2 elements are ceramic-based and are brittle at room temperature. They require careful handling during installation and furnace maintenance to avoid breakage.

Making the Right Choice for Your Goal

Selecting a furnace requires matching the heating element technology to your specific process requirements and budget.

- If your primary focus is general lab work or ashing below 1200°C: A furnace with traditional electric wire (FeCrAl) elements is the most cost-effective and suitable choice.

- If your primary focus is mid-range applications (up to 1600°C) requiring good uniformity: A furnace with silicon carbide (SiC) elements offers a balanced trade-off between performance and cost.

- If your primary focus is high-temperature metallurgy, sintering, or advanced materials research (above 1600°C): A furnace with molybdenum disilicide (MoSi2) elements is the necessary and definitive choice for performance.

Ultimately, understanding the heating element technology is the key to selecting a furnace that can truly meet the demands of your application.

Summary Table:

| Advantage | Description |

|---|---|

| Extreme Temperature Capability | Reaches up to 1,800°C, enabling processing of advanced ceramics and high-melting-point metals. |

| Enabling Advanced Metallurgy | Supports processes like metal injection molding (MIM) for precise debinding and sintering. |

| Superior Heat Uniformity | Ensures consistent temperature distribution for repeatable, high-quality outcomes. |

| High Process Efficiency | Faster heating rates reduce cycle times and energy consumption, boosting throughput. |

Ready to elevate your lab's capabilities with advanced high-temperature furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency